2025 Hypo Eutectoid Steel Market Insights: USA, Germany, and Japan Leading the Innovation Worth $596.54 Million

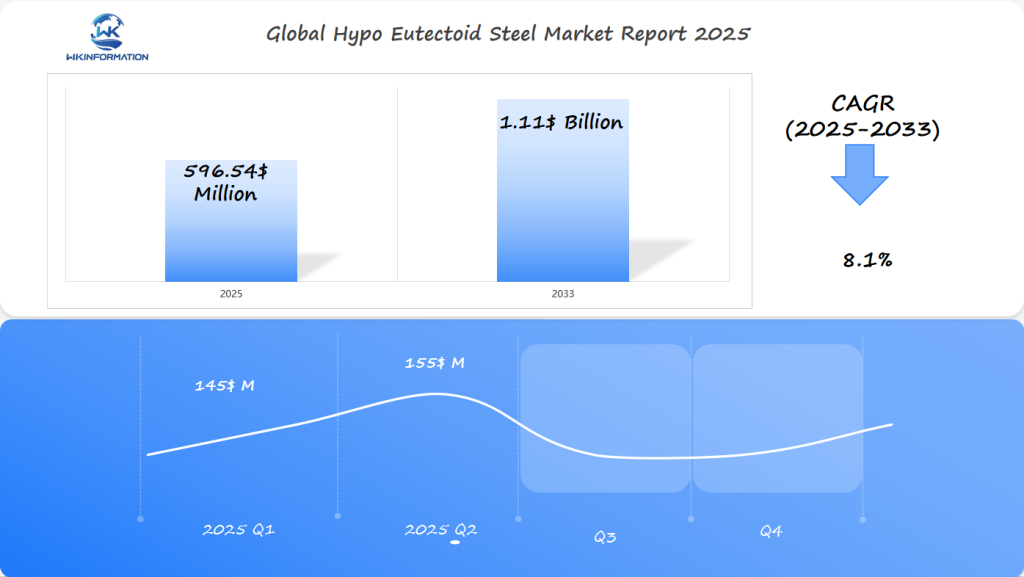

The Hypo eutectoid steel market will reach USD 596.54 Million in 2025 and is expected to reach USD 1.11 Billion by 2033, with a CAGR of 8.1% from 2025 to 2033.

- Last Updated:

Projected Market Insights for Hypo Eutectoid Steel in Q1 and Q2 of 2025

The Hypo Eutectoid Steel market is forecast to reach $596.54 million in 2025, with a CAGR of 8.1% from 2025 to 2033. In Q1, the market is projected to generate about $145 million, driven by increasing demand for high-performance materials in automotive and industrial applications. By Q2, the market size is expected to rise to approximately $155 million, reflecting robust growth.

The USA, Germany, and Japan are expected to be the most significant players in this market, owing to their advanced manufacturing sectors and strong demand for steel in heavy industries. Technological advancements and growing industrial production in these regions will further drive market expansion throughout the year.

Understanding the Factors Affecting the Hypo Eutectoid Steel Market

The hypo eutectoid steel market is influenced by complex factors.

Upstream Dynamics

Upstream dynamics focus on raw material sourcing, which plays a critical role in pricing and availability. Essential inputs like iron ore and carbon significantly impact cost structures. Fluctuations in raw material prices can lead to volatility in steel pricing, affecting overall market stability.

Downstream Dynamics

In the supply chain, downstream dynamics refer to the critical stages of processing and distribution. After acquiring raw materials, they go through different refining processes to create hypo eutectoid steel. Using efficient processing methods improves quality and performance. The distribution phase involves transporting finished products to various industries, requiring strong logistical systems to ensure on-time delivery.

Understanding these dynamics is essential for stakeholders who want to navigate the market successfully. By examining both upstream and downstream processes, companies can optimize their operations, reduce costs, and enhance supply chain efficiency. Engaging with these dynamics provides valuable insights into market trends and offers pathways for strategic decision-making in this evolving industry landscape.

Key Trends Influencing the Hypo Eutectoid Steel Market in 2025

Emerging technologies are radically transforming the hypo eutectoid steel production landscape. Advanced metallurgical techniques, such as controlled rolling and microalloying, enhance the mechanical properties of steel while reducing costs. These innovations not only improve performance but also widen the range of applications for hypo eutectoid steel in various industries.

Sustainability initiatives are equally crucial in shaping industry practices. As environmental concerns rise, there’s a significant shift towards more eco-friendly production methods. Carbon-neutral processes and the use of recycled materials are becoming standard practice among forward-thinking manufacturers. This shift is driven by strict regulations and growing consumer demand for sustainable products.

The combination of innovation and sustainability is setting new standards in the hypo eutectoid steel market, creating opportunities for growth while addressing environmental challenges. Industry leaders adopting these trends are poised to gain a competitive edge, pushing the market towards its projected valuation of $596.54 million by 2025.

Barriers and Restrictions Impacting the Hypo Eutectoid Steel Industry

Navigating the complex landscape of regulations is a critical challenge for the Hypo Eutectoid Steel Market. Stringent environmental standards often influence production processes, requiring manufacturers to adopt cleaner technologies. Compliance with these regulations ensures environmental safety but can lead to increased operational costs.

Trade Restrictions

Trade restrictions present another significant hurdle. International trade policies and tariffs can dramatically influence market dynamics. For instance, tariffs imposed on steel imports can escalate costs, impacting pricing strategies and competitiveness in global markets. These economic factors force companies to continually adapt their supply chain strategies to mitigate adverse impacts.

Cross-Border Trade Barriers

Cross-border trade barriers also complicate distribution networks. Differences in national standards and certification requirements mean that companies must navigate diverse regulatory landscapes to maintain smooth operations. This can lead to delays and increased administrative burdens, affecting the timely delivery of products.

Understanding these regulatory challenges is essential for stakeholders aiming to maintain a competitive edge in the Hypo Eutectoid Steel Market. By staying informed about evolving regulations and actively engaging in policy discussions, companies can better position themselves within this dynamic industry environment.

Geopolitical Factors Shaping the Hypo Eutectoid Steel Market

Geopolitical factors have a significant impact on the hypo eutectoid steel market, affecting both supply chains and market dynamics.

1. Geopolitical tensions

Geopolitical tensions can disrupt supply chains, leading to significant delays and increased costs. When countries experience diplomatic disputes or regional conflicts, the transportation and availability of raw materials and finished products often suffer. This disruption can cause fluctuations in pricing and availability, influencing global markets. Such risks are not just limited to localized effects; they also affect the world economy on a larger scale.

2. Impact of tariffs and trade agreements

The impact of tariffs and trade agreements also plays a crucial role in shaping the hypo eutectoid steel industry’s landscape. Tariffs imposed by one country on another can lead to increased production costs, which are often passed on to consumers. Trade agreements, on the other hand, can facilitate smoother transactions between countries by reducing or eliminating these tariffs. For instance, the NAFTA’s economic impact illustrates how such agreements can reshape market dynamics. The balance between protectionism and free trade significantly affects market competitiveness and strategic positioning.

3. International relations

International relations dictate how these geopolitical factors play out within the industry. As nations navigate their political landscapes, the hypo eutectoid steel market must adapt to changing policies and economic alliances. Understanding these dynamics is essential for stakeholders aiming to maintain stability and growth in this competitive sector.

Types of Hypo Eutectoid Steel and Their Technological Advancements

Understanding the types of steel within the hypo eutectoid category is crucial for optimizing applications and performance. These steels are characterized by a carbon content typically less than 0.8%, allowing them to exhibit unique mechanical properties that make them suitable for various industrial uses.

Breakdown of Different Types

- Low Carbon Steels: Often containing up to 0.3% carbon, these steels are known for their ductility and weldability, making them ideal for manufacturing processes where flexibility is necessary.

- Medium Carbon Steels: Containing approximately 0.3% to 0.6% carbon, these steels offer a balance between strength and ductility, often used in construction and automotive manufacturing.

Technological Advancements

Recent technological advancements have enhanced the performance and applicability of hypo eutectoid steels:

- Advanced Heat Treatment Techniques: Such processes refine the grain structure, enhancing strength without sacrificing ductility.

- Alloying Innovations: Incorporating elements like vanadium or niobium has led to improved toughness and resistance to wear.

- Additive Manufacturing Adaptations: Enabling complex geometries and reducing waste in production, expanding their use in high-tech industries.

These innovations ensure that hypo eutectoid steels remain at the forefront of material science, continually adapting to meet evolving industry demands.

Applications of Hypo Eutectoid Steel in Various Industries

Hypo eutectoid steel has become a cornerstone in several industries due to its unique properties and versatility. Its applications span across automotive manufacturing, construction projects, and industrial machinery.

1. Automotive Sector

In the automotive industry, hypo eutectoid steel is highly valued for its durability and strength. It is commonly used in the manufacturing of structural parts like car frames and chassis, which need materials that can bear heavy pressure while still being lightweight. The capability to improve fuel efficiency without sacrificing safety makes hypo eutectoid steel a top choice.

2. Construction Industry

The construction industry relies heavily on hypo eutectoid steel for infrastructural development. Its high tensile strength and resistance to wear make it ideal for use in building frameworks, reinforcement bars, and girders. These properties ensure long-term stability and safety in large-scale construction projects.

3. Industrial Machinery

Hypo eutectoid steel is used in industrial machinery to make machine parts that require accuracy and strength. It is often used in gears, shafts, and bearings where high performance under stress is important.

These different uses show how important hypo eutectoid steel is in many industries, helping progress and ensuring dependability in key economic activities.

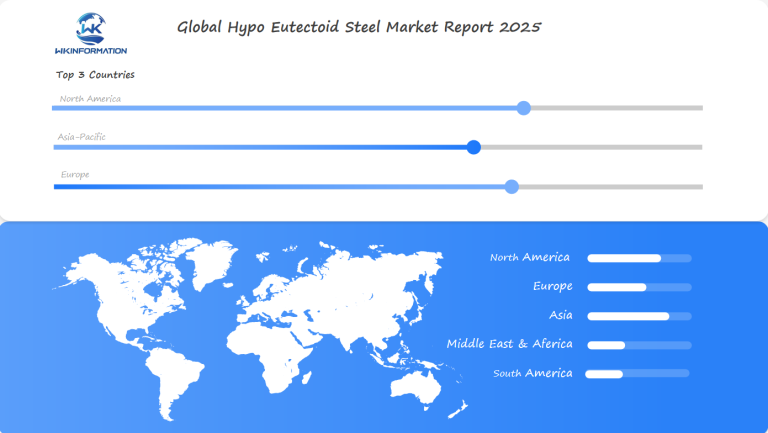

Global Market Performance: Hypo Eutectoid Steel Market Across Key Regions

The hypo eutectoid steel market shows different performances in important regions, each playing a significant role in the expected market value of $596.54 million by 2025.

North America: Technological Advancements in Automotive and Aerospace Industries

North America is a key player, with the United States leading the way in technological advancements and innovative applications in the automotive and aerospace industries. The region’s focus on high-strength materials positions it as a leader in global market performance.

Europe: Sustainable Practices in Manufacturing

In Europe, Germany stands out due to its strong manufacturing sector and commitment to sustainable practices. German companies prioritize energy-efficient production techniques, aligning with strict EU environmental regulations, which gives them a competitive advantage.

Asia-Pacific: Research and Development Driving Growth

Asia-Pacific, particularly Japan, is experiencing impressive growth driven by their commitment to research and development. Japanese manufacturers place a high priority on precision engineering, improving the quality and versatility of hypo eutectoid steel. Their investments in modern infrastructure projects also drive demand within the region.

These regional factors not only highlight different market strategies but also emphasize the importance of innovation and sustainability in maintaining a competitive position worldwide. Understanding these subtleties provides valuable insights for stakeholders looking to take advantage of emerging opportunities in the hypo eutectoid steel industry.

USA Hypo Eutectoid Steel Market: Market Trends and Growth Insights

The USA hypo eutectoid steel market is witnessing steady growth, driven by its widespread applications in industries such as automotive, construction, and manufacturing. This type of steel, which contains less than 0.8% carbon, is favored for its balance of strength, ductility, and machinability, making it a crucial material in structural components and machinery parts. The market is benefiting from advancements in steel processing technologies, including improved heat treatment methods that enhance the mechanical properties of hypo eutectoid steel.

Additionally, sustainability initiatives in the U.S. steel industry, such as increased recycling and lower carbon emissions in production, are shaping market trends. With infrastructure development projects and the resurgence of domestic manufacturing, demand for high-quality, cost-effective steel solutions is expected to remain strong.

Germany Hypo Eutectoid Steel Market: Key Developments and Forecasts

Germany’s hypo eutectoid steel market is driven by the country’s strong engineering and manufacturing sectors, particularly in the automotive and machinery industries. Precision engineering and high-performance requirements have led to the adoption of advanced steel grades that offer enhanced strength and durability. Key developments in the German market include innovations in alloy compositions and metallurgical processes that improve the performance and sustainability of hypo eutectoid steel.

Moreover, the push for green steel production—aiming to reduce CO₂ emissions through cleaner manufacturing technologies—is influencing market dynamics. Forecasts indicate stable growth in the coming years, with demand fueled by Germany’s industrial sector, ongoing infrastructure projects, and the transition toward more sustainable metal production.

Japan Hypo Eutectoid Steel Market: Market Insights and Innovations

The hypo eutectoid steel market in Japan is characterized by technological innovation and a strong emphasis on high-quality materials for precision manufacturing. The country’s advanced automotive, robotics, and construction industries rely on hypo eutectoid steel for its excellent machinability and structural integrity. Japanese manufacturers are at the forefront of developing new processing techniques, such as microalloying and thermomechanical treatments, to improve the performance of hypo eutectoid steel.

Additionally, the shift towards eco-friendly production methods, including hydrogen-based steelmaking, is shaping the market’s future. With Japan’s focus on technological advancements and sustainable manufacturing, the hypo eutectoid steel market is expected to see continued growth, supported by investments in research and development.

Looking Ahead: What’s Next for the Hypo Eutectoid Steel Market in 2025?

The future outlook 2025 for the hypo eutectoid steel market suggests a dynamic evolution driven by current trends and challenges. Technological advancements are set to enhance production efficiency, reduce costs, and improve material properties. The growing emphasis on sustainability will likely push manufacturers towards adopting eco-friendly practices and materials.

Key predictions include:

- Increased Demand: As industries such as automotive and construction continue to grow, the demand for hypo eutectoid steel is expected to surge.

- Technological Integration: Innovations like AI in manufacturing processes are anticipated to streamline production, offering better quality control and reduced wastage. This technological integration will be crucial for meeting the rising demand while maintaining quality.

- Regulatory Pressures: Stricter environmental regulations could pose challenges but also drive innovation in cleaner production techniques. Such regulatory pressures require industry players to remain agile, focusing on sustainable growth strategies while adapting to regulatory landscapes. This proactive approach ensures they harness opportunities emerging from technological and market shifts.

Competitive Analysis in the Hypo Eutectoid Steel Market

Major Players:

1. PepsiCo Inc. —— United States

2. The Coca-Cola Company —— United States

3. Cott Corporation —— Canada

4. Dohler GmbH —— Germany

5. The Kraft Heinz Company —— United States

6. Dr. Pepper Snapple Group Incorporated —— United States

7. Monster Beverage Corporation —— United States

8. Nestlé SA —— Switzerland

9. Ingredion Incorporated —— United States

10. Kerry Group plc —— Ireland

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Hypo Eutectoid Steel Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The hypo eutectoid steel market demonstrates significant potential for future growth, driven by technological advancements and increasing demand across key sectors. The market’s expansion is fueled by its applications in the automotive and construction industries, where the need for lightweight and durable materials is paramount. As global industrialization and urbanization continue, the market is poised to capitalize on emerging opportunities. Stakeholders should remain vigilant, leveraging insights from market analysis to navigate challenges and harness growth potential effectively.

Global Hypo Eutectoid Steel Market Report (Can Read by Free sample) – Table of Contents Chapter 1: Hypo Eutectoid Steel Market Analysis Overview Competitive Forces Analysis (Porter’s Five Forces) Strategic Growth Assessment (Ansoff Matrix) Industry Value Chain Insights Regional Trends and Key Market Drivers Hypo Eutectoid Steel Market Segmentation Overview Chapter 2: Competitive Landscape Global Hypo Eutectoid Steel players and Regional Insights oKey Players and Market Share Analysis Sales Trends of Leading Companies oYear-on-Year Performance Insights Competitive Strategies and Market Positioning oKey Differentiators and Strategic Moves Chapter 3: Hypo Eutectoid Steel Market Segmentation Analysis Key Data and Visual Insights oTrends, Growth Rates, and Drivers Segment Dynamics and Insights oDetailed Market Analysis by Segment Chapter 4: Regional Market Performance Consumer Trends by Region oHistorical Data and Growth Forecasts Regional Growth Factors oEconomic, Demographic, and Technological Impacts Challenges and Opportunities in Key Regions Regional Trends and Market Shifts Key Cities and High-Demand Areas Chapter 5: Hypo Eutectoid Steel Emerging and Untapped Markets Growth Potential in Secondary Regions oTrends, Challenges, and Opportunities Chapter 6: Product and Application Segmentation Product Types and Innovation Trends Application-Based Market Insights Chapter 7: Hypo Eutectoid Steel Consumer Insights Demographics and Buying Behaviors oTarget Audience Profiles Chapter 8: Key Findings and Recommendations Summary of Hypo Eutectoid Steel Market Insights Actionable Recommendations for Stakeholders

Chapter 1: Hypo Eutectoid Steel Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Hypo Eutectoid Steel MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Hypo Eutectoid Steel players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Hypo Eutectoid Steel Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Hypo Eutectoid Steel Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Hypo Eutectoid Steel Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofHypo Eutectoid Steel Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected financial outlook for the hypo eutectoid steel market in 2025?

The hypo eutectoid steel market is projected to reach an estimated financial outlook of $596.54 million by 2025.

What are the upstream and downstream factors affecting the hypo eutectoid steel market?

Upstream factors include the sourcing of raw materials, which affects pricing and availability. Downstream factors focus on the processing and distribution stages within the supply chain.

What key trends are influencing the hypo eutectoid steel market in 2025?

Emerging technologies in production and sustainability initiatives are key trends shaping the hypo eutectoid steel market in 2025.

What barriers and restrictions impact the hypo eutectoid steel industry?

The industry faces regulatory challenges, trade restrictions between countries, and various economic factors that affect production and distribution.

How do geopolitical factors shape the hypo eutectoid steel market?

Geopolitical tensions can disrupt supply chains, while tariffs and trade agreements significantly influence market dynamics.

Industries that use hypo eutectoid steel

Hypo eutectoid steel is widely used in industries such as:

- Automotive manufacturing

- Construction projects

- Industrial machinery