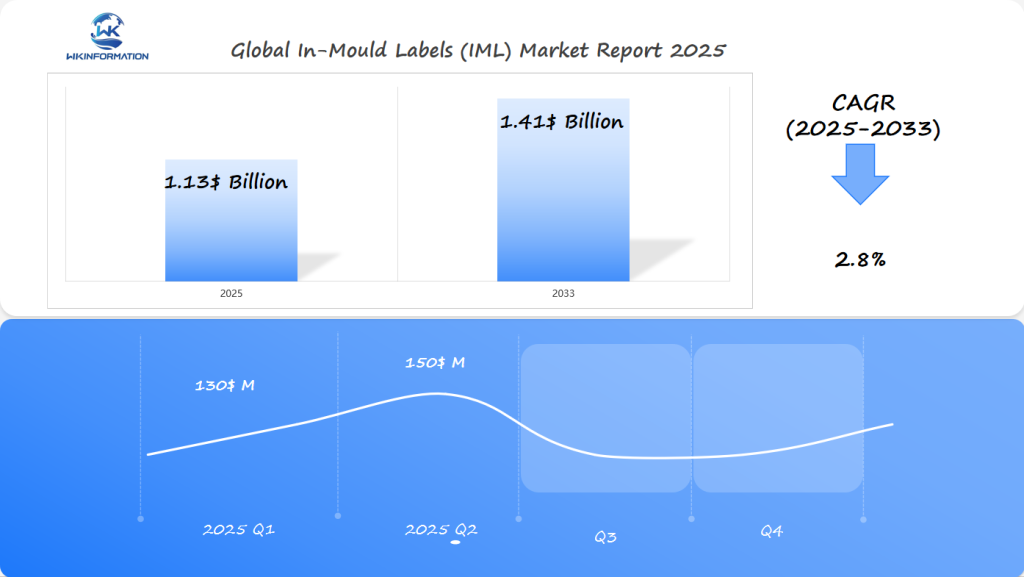

2025 In-Mould Labels (IML) Market: Capturing $1.13 Billion Potential, Supported by Markets in U.S., Germany & China

Explore the dynamic In-Mould Labels (IML) market trends and growth opportunities across the U.S., Germany, and China. Discover key technological advancements, sustainability initiatives, and market projections through 2025, featuring insights on major industry players and emerging challenges in the global packaging sector.

- Last Updated:

In-Mould Labels (IML) Market Forecast for Q1 and Q2 of 2025

The global In-Mould Labels (IML) market is projected to reach USD 1.13 billion in 2025, with a CAGR of 2.8%. In Q1 2025, the global market is expected to be around USD 130 million, as the industry sees steady demand. By Q2 2025, the market is forecast to reach approximately USD 150 million, with gradual growth expected across key regions like the U.S., Germany, and China, driven by the rising demand for packaging solutions.

This growth is slower compared to other markets, but shows steady progress in the first half of the year.

The In-Mould Labels (IML) Supply Chain Explained

Understanding the IML supply chain is essential for grasping how this innovative packaging solution reaches its end-users efficiently. The supply chain is divided into two main components: upstream and downstream processes, each playing a crucial role in delivering high-quality IML products.

Upstream Processes

The upstream segment of the IML supply chain involves critical elements such as raw materials and manufacturing processes. Key materials used include:

- Polypropylene (PP): Favored for its recyclability and compatibility with existing systems.

- Inks and Coatings: Essential for creating vibrant, durable labels that withstand the rigors of packaging.

Manufacturing processes are integral to the production of IMLs. Injection molding and blow molding are predominant techniques, where labels are integrated directly into the packaging during fabrication. This integration provides durability and resistance to peeling or fading. The precision required in these processes demands advanced machinery capable of high-speed operations without compromising quality.

Downstream Processes

Downstream aspects focus on distribution channels and end-users. Efficient distribution ensures that IML products reach their intended markets swiftly. Key channels include:

- Direct Sales: Often used by larger manufacturers to maintain control over supply.

- Distributors: Facilitate broader market reach, especially in regions where direct sales networks are limited.

- Online Platforms: Increasingly significant as digital commerce grows.

End-users span various industries:

- Food & Beverage: Demands tamper-evident and visually appealing labels.

- Pharmaceuticals: Seeks durable labeling for safety compliance.

- Consumer Goods: Prefers customizable options to enhance brand visibility.

Role of Technology in Optimizing the IML Supply Chain

Technology plays a pivotal role in optimizing every stage of the IML supply chain. Automation within manufacturing improves efficiency, allowing for faster production cycles while maintaining high standards. Digital printing technology has revolutionized customization, enabling brands to create unique designs that cater to specific consumer preferences.

Furthermore, advancements in logistics software aid in real-time tracking and management of inventory levels across multiple locations. This capability reduces delays, improves cost-efficiency, and enhances customer satisfaction by ensuring timely delivery of products.

Understanding the intricacies of the IML supply chain—from material selection through to technological enhancements—reveals how this robust system supports the growing demand across various industries worldwide.

Innovations and Trends in In-Mould Labels (IML) Technology

Recent Advancements in Molding Technology

The IML market is undergoing significant changes, mainly due to improvements in molding technology. Modern injection molding machines now use advanced robotics and automation, making them more precise and efficient. This technological advancement allows manufacturers to create high-quality labels with complex designs more quickly, saving time and money. For example, the use of robotics ensures that labels are consistently placed within molds, reducing mistakes and increasing production.

Digital Printing: Customization and Brand Visibility

Digital printing has revolutionized the world of IML packaging solutions. Its capability to deliver sharp graphics and bright colors enables brands to achieve unmatched customization, catering to individual consumer preferences. This technology supports short print runs without sacrificing quality, making it perfect for limited edition products or seasonal offerings. The versatility of digital printing not only enhances brand visibility but also sets products apart in competitive markets.

“Digital printing’s role in IML is crucial for brands aiming to stand out with distinctive and attention-grabbing designs.”

Sustainability Trends Shaping the Future of IML

With increasing environmental concerns, sustainable packaging solutions are becoming more popular in the IML market. Companies are adopting eco-friendly practices such as using recyclable materials like polypropylene. This shift aligns with global efforts to reduce waste and promote circular economies. Additionally, innovations in biodegradable materials are opening doors for more sustainable options, meeting consumer demand for environmentally friendly products.

- Recyclable Materials: Polypropylene-based IMLs stand out for their recyclability and compatibility with existing recycling systems.

- Biodegradable Options: Research into materials that break down naturally offers promising avenues for future development.

These trends emphasize how technological advancements are not only improving efficiency but also reshaping market expectations for quality and sustainability in packaging solutions.

Challenges Facing the In-Mould Labels (IML) Industry

The In-Mould Labels (IML) market has its own set of challenges that businesses need to overcome in order to grow and innovate. The main issues here are high raw material costs and problems with the supply chain.

Impact of Raw Material Costs

The prices of raw materials, especially polypropylene, can be unpredictable. This directly affects how much it costs to produce IML products. When manufacturers can’t predict their costs accurately, it becomes difficult for them to plan their operations effectively.

Risks from Supply Chain Disruptions

Global events like pandemics or political conflicts can cause delays in getting raw materials. This, in turn, affects production schedules and increases costs. It’s essential for companies to have a strong supply chain in place so they can always deliver their products on time.

Regulatory Challenges

Following environmental laws and industry standards is important, but it can also be a burden on businesses. Sometimes, these strict rules require companies to spend more money on research and development in order to come up with eco-friendly solutions without sacrificing quality.

Competition in the Market

There are many players in the IML industry competing against each other. This competition puts pressure on companies to lower their prices in order to keep their customers. However, this can lead to price wars where everyone ends up making less profit.

Strategies for Overcoming Challenges

To deal with these challenges, businesses need to be flexible and adapt their strategies accordingly. Here are some ways they can do this:

- Focus on innovation: Instead of just relying on low prices, companies should invest in developing new and better products that stand out from the competition.

- Strengthen supply chains: By building strong relationships with suppliers and diversifying sources of raw materials, businesses can reduce the impact of disruptions on their operations.

- Invest in compliance initiatives: Rather than seeing regulations as obstacles, companies should view them as opportunities to differentiate themselves by offering sustainable packaging solutions.

By implementing these strategies, IML companies can navigate through the challenges they face and position themselves for long-term success.

The Impact of Global Politics on In-Mould Labels (IML) Production and Trade

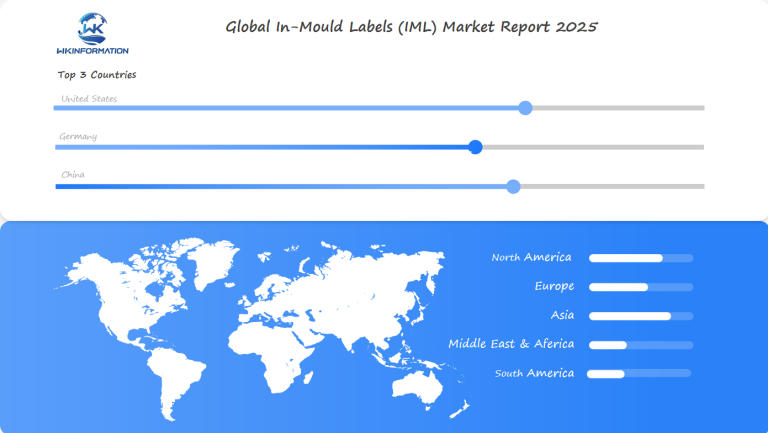

Global politics impact the dynamics of the In-Mould Labels (IML) market significantly, especially in relation to trade policies and geopolitical influences. Key regions like the U.S., Germany, and China are pivotal in shaping these dynamics through their trade relations. Understanding how these interactions affect the IML market is crucial for stakeholders aiming to navigate this competitive landscape strategically.

Trade Relations

1. U.S., Germany, and China

These countries are central players in the global IML market. Their trade relationships influence not only market dynamics but also pricing strategies and supply chain efficiencies. As these regions engage in trade negotiations or conflicts, the ripple effects can alter market conditions, potentially impacting availability and costs of raw materials. How geopolitics is changing trade is a pertinent aspect to consider here.

2. Trade Policies

Variations in tariffs, import/export duties, and trade agreements between these nations can either facilitate smooth market operations or create barriers that disrupt supply chains. For instance, any increase in tariffs on plastic materials could raise production costs for IML producers, affecting profit margins and pricing strategies.

Political Factors Influencing Manufacturing

1. Manufacturing Locations

Political stability and policy frameworks play a critical role in determining optimal manufacturing locations for IML production. Countries offering favorable business environments with minimal bureaucratic hurdles attract more investment from multinational companies. Conversely, regions plagued by political instability might deter investment due to perceived risks.

2. Cost Implications

Political factors such as labor laws, environmental regulations, and energy policies directly influence production costs. Manufacturers must account for these variables when selecting locations for their operations to ensure cost-efficiency while complying with local regulations.

Tariffs and Trade Agreements

1. Tariffs

The imposition of tariffs can have a substantial impact on the IML industry. For example, increased tariffs on imported components may lead manufacturers to seek alternative suppliers or shift production to regions with lower tariff rates.

2. Trade Agreements

Agreements such as the United States-Mexico-Canada Agreement (USMCA) or those within the European Union can dictate terms of trade that benefit certain regions over others. These agreements often result in reduced tariffs and streamlined customs procedures, which can enhance the competitiveness of IML products in international markets.

Understanding how these geopolitical influences shape the global IML industry is essential for businesses to adapt their strategies effectively. By aligning operations with favorable political climates and proactively responding to changes in trade policies, companies can better mitigate risks associated with global politics impact on IML production and trade.

In-Mould Labels (IML) Market Segmentation by Type and Application Area

The In-Mould Labels (IML) market segmentation offers a detailed breakdown of product types and application areas, highlighting the versatility and adaptability of IML technology in various industries.

Types of In-Mould Labels by Material

1. Polypropylene (PP)

Polypropylene emerges as a frontrunner in the IML segment due to its unique properties. Known for its recyclability, PP-based IMLs align seamlessly with sustainability goals, making them highly desirable.

- Their compatibility with existing recycling systems ensures a minimal environmental footprint while maintaining high durability and resistance to wear.

2. Polyethylene (PE)

Offering flexibility and toughness, PE is another popular material in IML production. Its application is notable in scenarios requiring robust packaging solutions that withstand varied conditions.

3. Other Materials

While PP and PE dominate, other materials like polystyrene and polycarbonate find niche applications based on specific industry needs. Each material offers distinct advantages tailored to particular use cases.

Application Areas Across Industries

Food & Beverage Industry

The demand for visually appealing and durable packaging drives the adoption of IMLs in food & beverage sectors. Products benefit from labels that resist moisture and maintain integrity over time, crucial for maintaining freshness and brand appeal.

Pharmaceuticals

In pharmaceuticals, IMLs provide tamper-evident solutions, enhancing safety standards. This feature is critical given the need for secure packaging that ensures consumer trust and compliance with stringent regulations.

Cosmetics

Cosmetic brands utilize IMLs to achieve high-resolution designs that enhance product aesthetics. The ability to deliver vibrant colors and intricate designs boosts shelf appeal, a significant factor in consumer purchasing decisions.

Automotive and Industrial Applications

Beyond consumer goods, IMLs are increasingly used in automotive components where label durability against wear and chemicals is paramount. Industrial applications benefit similarly from the robustness and clarity offered by these labels.

The segmentation of the IML market by type underscores polypropylene’s role as a pivotal material choice due to its environmental benefits and versatility. Meanwhile, exploring the diverse application areas reveals how industries leverage IML technology to meet specific needs—from enhancing product safety in pharmaceuticals to boosting visual appeal in cosmetics. This comprehensive understanding of IML segmentation provides valuable insights into its broad market potential.

Application Market Analysis: The Role of In-Mould Labels (IML) in Packaging Solutions

In-mould labels (IML) have become a crucial part of packaging solutions in many industries. They offer benefits that improve both function and appearance. One of the main industries benefiting from IML is the food and beverage industry.

Benefits of IML in the Food and Beverage Industry

In this industry, IML provides features that prevent tampering and resist moisture. This ensures that products are safe and have a longer shelf life. Additionally, the ability to include detailed graphics directly into the packaging mold enhances brand visibility, making it an appealing choice for manufacturers looking to stand out on the shelf.

Advantages of IML in the Pharmaceutical Sector

The pharmaceutical sector also takes advantage of what IML can do. With strict rules for labeling, IML offers durability by preventing labels from peeling or fading. This is essential for staying compliant and ensuring consumer safety. Furthermore, incorporating barcodes and QR codes within labels allows for efficient inventory management and traceability.

Applications of IML in Consumer Goods

In the world of consumer goods, IML’s flexibility in design and customization helps products stand out. Brands have the opportunity to explore different textures and finishes without sacrificing quality or functionality. Moreover, using recyclable materials like polypropylene in IML aligns with the increasing demand from consumers for sustainable packaging options.

These qualities make IML an essential tool for industries seeking to blend creativity with practicality in their packaging strategies.

Regional Insights into the In-Mould Labels (IML) Market: 2025 Outlook for U.S., Germany & China

U.S. IML Market Insights

The U.S. In-Mould Labels (IML) market is poised for growth, largely driven by the pharmaceutical sector’s demand for tamper-evident solutions. Consumer preferences in the U.S. are shifting towards high-quality, durable packaging that enhances product safety and integrity. This trend is crucial for pharmaceuticals where compliance with stringent regulatory frameworks necessitates reliable labeling solutions.

- Growth Drivers:Increased consumption of packaged foods.

- Advancements in digital printing technologies.

- Rising demand for sustainable packaging solutions.

Key players like CCL Industries Inc. and Avery Dennison Corp. are focusing on innovation and strategic acquisitions to enhance their market presence, adapting to industry requirements and consumer expectations.

Germany IML Market Trends

In Germany, the IML market is significantly influenced by the beverage industry’s quest for eco-friendly solutions. The country’s strong environmental regulations drive a focus on sustainable materials such as polypropylene, known for its recyclability.

- Growth Drivers:Strong emphasis on sustainable practices.

- Regulatory frameworks promoting eco-friendly materials.

- Industry demand for high-resolution, customizable labels.

Major contributors to this market include companies like Fuji Seal International Inc., which are leveraging sustainable technology advancements to cater to evolving industry demands while maintaining competitiveness through innovation.

China IML Market Growth

China’s expanding consumer base and increasing demand for packaged goods position it as a crucial player in the global IML landscape. The country’s rapid industrialization has created a robust market environment favoring innovative and efficient packaging solutions.

- Growth Drivers:Rising consumer demand for packaged goods.

- Government initiatives supporting industrial growth.

- Technological advancements facilitating efficient production processes.

Prominent companies such as Huhtamaki Oyj and Constantia Flexibles Group are capitalizing on these growth opportunities by expanding their operations and investing in local partnerships to strengthen their foothold in the Chinese market.

The dynamic nature of each region’s market necessitates a keen understanding of local consumer preferences, regulatory conditions, and competitive strategies. As these factors continue to evolve, they will play a pivotal role in shaping the future trajectory of the In-Mould Labels (IML) industry across these key regions.

U.S. In-Mould Labels (IML) Market Analysis

The U.S. market for In-Mould Labels (IML) is growing, driven by several key factors. The pharmaceutical sector is a significant driver, with an increasing demand for tamper-evident and durable packaging solutions that IML provides. Emphasizing safety and product integrity, the sector’s reliance on IML is expected to continue expanding.

1. Consumer Preferences

Heightened consumer awareness towards eco-friendly and sustainable packaging solutions plays a pivotal role in shaping the IML market in the U.S. Polypropylene-based IMLs are favored due to their recyclability, aligning with the growing environmental consciousness among consumers.

2. Technological Advancements

The integration of digital printing technologies into IML production allows for high-resolution graphics and customization. This capability enhances brand visibility and supports product differentiation, attracting industries across food & beverage and personal care sectors.

3. Regulatory Environment

Stringent regulations pertaining to packaging standards ensure that IML remains a viable choice for manufacturers seeking compliance without compromising on quality or aesthetics.

Key players such as CCL Industries Inc. and Avery Dennison Corp. dominate this space, focusing on innovation and strategic partnerships to strengthen their foothold in the market. Their efforts in advancing sustainable solutions align well with industry demands, fueling market growth in the region.

Germany In-Mould Labels (IML) Market Analysis

Germany’s IML market is experiencing strong growth, mainly driven by the demand for sustainable packaging solutions in the beverage industry. The following factors are contributing to this trend:

1. Eco-friendly Initiatives

German consumers and regulations prioritize environmentally conscious products. IML technology, with its ability to integrate labels during the molding process, offers a sustainable solution that aligns with these values.

2. Technological Advancements

The adoption of advanced molding technologies enhances the durability and aesthetic appeal of IMLs, meeting the high standards expected by German manufacturers and consumers alike.

3. Industry Dynamics

The beverage sector in Germany is a significant contributor to the IML market’s expansion, as brands seek durable and visually appealing packaging that withstands moisture and temperature variations.

Notable Players in Germany’s IML Market:

- CCL Industries Inc.

- Avery Dennison Corp.

- Constantia Flexibles Group

These companies are actively investing in research and development to introduce innovative IML solutions that cater to evolving consumer preferences. Strategic partnerships and acquisitions are also prevalent as businesses strive to fortify their market positions. By understanding these dynamics, stakeholders can better navigate Germany’s rapidly evolving IML landscape.

China In-Mould Labels (IML) Market Analysis

China presents a significant growth opportunity for the In-Mould Labels (IML) market, driven by increasing consumer demand for packaged goods. The rapidly expanding middle class in urban areas is contributing to this surge, with preferences leaning towards high-quality and visually appealing packaging.

Key Growth Drivers in the Chinese Market

The following factors are driving the growth of the IML market in China:

- Rising Demand for Packaged Foods: Urbanization and changing lifestyles are boosting the consumption of packaged foods, necessitating innovative packaging solutions like IML.

- Technological Advancements: Integration of cutting-edge digital printing techniques allows for high-resolution, customizable labels which cater to local brands seeking differentiation in a competitive market.

- Sustainability Initiatives: As global awareness around environmental issues grows, Chinese manufacturers are increasingly adopting sustainable IML solutions that align with regulations and consumer expectations. Polypropylene-based IMLs are particularly popular due to their recyclability.

Major Players in China’s IML Market

Key players in China’s IML market focus on strategic partnerships and local manufacturing capabilities to efficiently meet domestic demand. Companies such as Huhtamaki Oyj and Constantia Flexibles Group leverage their global expertise while customizing solutions to regional needs, ensuring competitiveness in this rapidly growing market.

Future Development Analysis: The Future Role of In-Mould Labels (IML) in Sustainable Packaging Solutions

Technological advancements continue to play a crucial role in shaping the future of IML packaging sustainability. As industries work towards their sustainability goals, it is essential to integrate eco-friendly materials and processes into IML solutions. Experts predict that innovations in biodegradable and compostable plastics will greatly improve the sustainability profile of IML packaging.

1. Technological Advancements

Research and development efforts are focusing on creating new polymer blends that not only provide durability but also reduce environmental impact. Improved recycling methods for polypropylene-based IMLs are expected to emerge, increasing their appeal as a sustainable choice. The incorporation of smart technologies, such as QR codes embedded in labels, offers additional value by enabling consumers to easily access recycling information.

2. Consumer Preferences

There’s a growing shift among consumers towards environmentally friendly products. This change is influencing packaging choices across various sectors. The demand for sustainable packaging is driving manufacturers to adopt IML solutions that align with eco-conscious values. Companies are increasingly prioritizing transparency in their supply chain and production practices, which includes adopting greener labeling technologies.

Consumer awareness regarding environmental issues is higher than ever. Brands leveraging IML technology can offer durable, visually appealing packaging that meets both aesthetic and sustainability standards. This balance enhances brand loyalty and positions companies as leaders in responsible packaging.

3. Market Implications

As sustainable practices become industry norms, companies investing in advanced IML technologies may gain competitive advantages. The future likely holds increased collaboration between material scientists, designers, and manufacturers to develop innovative solutions that address both performance and environmental concerns.

In essence, the future of IML lies in its ability to adapt to evolving consumer demands and regulatory pressures while continuously innovating towards a more sustainable tomorrow.

Competitor Analysis: Major Players in the In-Mould Labels (IML) Market

The In-Mould Labels (IML) market is characterized by several key players who significantly influence its dynamics.

- Avery Dennison

- CCL Industries

- Constantia Flexibles

- Coveris Holdings

- Huhtamaki Group

- Multi-Color Corporation

- Innovia Films

- Jindal Films

- Taghleef Industries

- EVCO Plastics

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global In-Mould Labels (IML) Market Report |

| Base Year | 2024 |

| Segment by Type |

· Polypropylene (PP) · Polyethylene (PE) · Other Materials |

| Segment by Application |

· Food & Beverages · Pharmaceuticals · Cosmetics · Automotive and Industrial Applications · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The future outlook for the IML market is bright, supported by a combination of technological advancements, changing consumer preferences, and increasing demand for sustainable packaging solutions. Stakeholders who are considering investing or innovating in this area should pay attention to several key trends:

- Technological Advancements: The integration of digital printing technologies and improvements in molding processes are set to enhance customization and efficiency, driving further adoption of IML solutions.

- Sustainability Focus: As environmental concerns rise, the shift towards eco-friendly packaging is expected to boost the demand for polypropylene-based IMLs due to their recyclability.

- Regional Growth Drivers:

- U.S.: Largely driven by pharmaceutical demands for tamper-evident solutions.

- Germany: Emphasis on sustainable solutions within the beverage industry presents significant opportunities.

- China: Rising consumer appetite for packaged goods indicates a robust expansion potential.

Investors and innovators should leverage these dynamics to capture growing opportunities in the In-Mould Labels (IML) market, positioning themselves strategically to meet future demands across key regions.

Global In-Mould Labels (IML) Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: In-Mould Labels (IML) Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- In-Mould Labels (IML)Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global In-Mould Labels (IML)players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: In-Mould Labels (IML) Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: In-Mould Labels (IML) Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: In-Mould Labels (IML) Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofIn-Mould Labels (IML)Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are In-Mould Labels (IML) and why are they significant in the packaging industry?

In-Mould Labels (IML) are labels that are applied during the molding process of plastic containers, providing a seamless and durable finish. They are significant in the packaging industry due to their ability to enhance product visibility, improve brand recognition, and offer customization options while maintaining sustainability.

What challenges does the IML market currently face?

The IML market faces several challenges including rising raw material costs, supply chain disruptions, regulatory hurdles impacting production, and intense market competition affecting pricing strategies. These factors can hinder growth and innovation within the industry.

How is technology influencing the IML supply chain?

Technology plays a crucial role in optimizing the IML supply chain by enhancing manufacturing processes, improving distribution efficiency, and facilitating digital printing, which allows for greater customization and brand visibility in packaging solutions.

What are the current trends in IML technology?

Current trends in IML technology include advancements in molding techniques, increased adoption of digital printing for better customization, and a strong shift towards sustainable packaging solutions. These trends are shaping the future of IML by addressing consumer demands for eco-friendly products.

How do global politics affect the In-Mould Labels (IML) market?

Global politics significantly impact the IML market through trade relations between key regions like the U.S., Germany, and China. Political factors influence manufacturing locations, costs for producers, and trade policies such as tariffs and agreements that shape the overall dynamics of the global IML industry.

What is the outlook for the In-Mould Labels (IML) market by 2025?

The outlook for the IML market by 2025 indicates strong growth opportunities across key regions. Factors such as evolving consumer preferences towards sustainable packaging, technological advancements, and strategic positioning of major players will drive this growth, making it an attractive sector for investment and innovation.