$44.87 Billion Linear Actuator Market Projected to Grow in the U.S., Germany, and Japan by 2025

Explore the Linear Actuator Market’s growth, trends, and innovations, including automation, sustainability, and compact designs driving industry advancements.

- Last Updated:

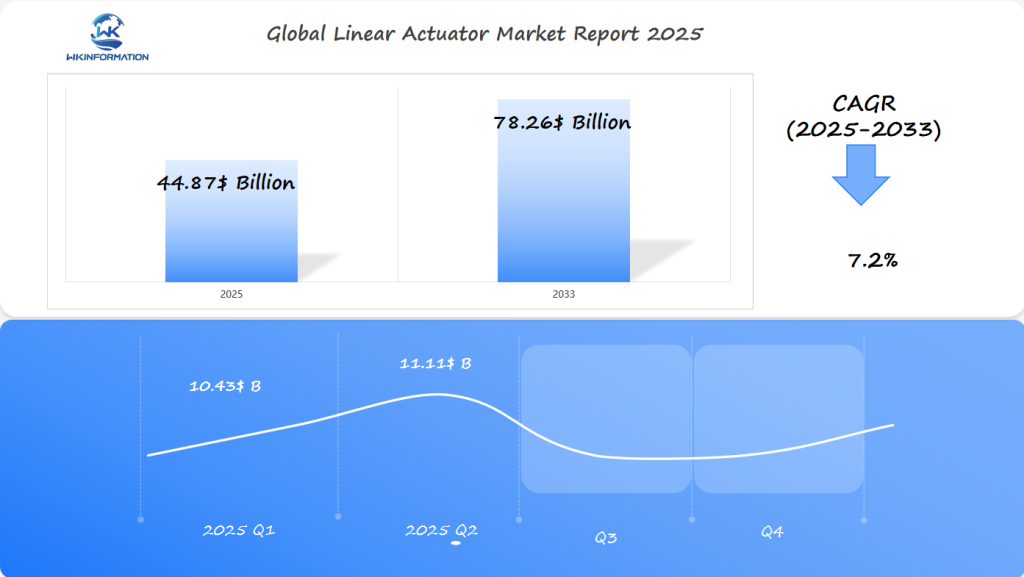

Projected Market Insights for Linear Actuator in Q1 and Q2 of 2025

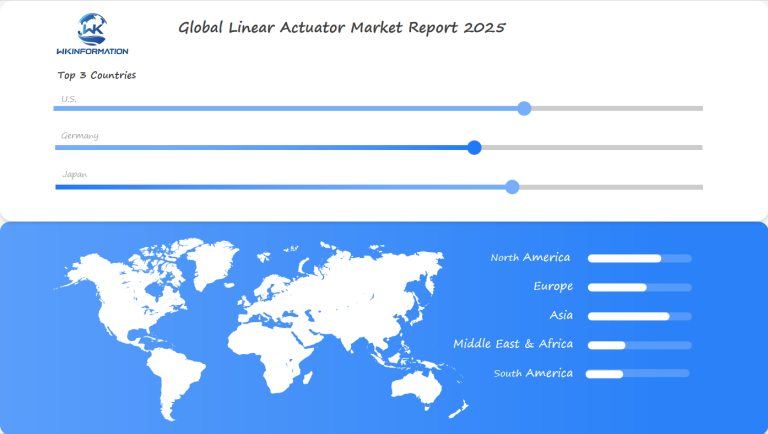

The Linear Actuator market is expected to reach $44.87 billion in 2025, with a CAGR of 7.2% from 2025 to 2033. In Q1, the market is projected to generate around $10.43 billion, driven by the demand from industries such as automotive, robotics, and healthcare for precision control mechanisms. By Q2, the market is expected to rise to approximately $11.11 billion, as applications in electric vehicles (EVs) and automation technologies continue to expand. The U.S., Germany, and Japan are key markets for linear actuators.

The U.S. is experiencing rapid growth in the EV sector, which is increasing the demand for actuators, while Germany and Japan are strong in automation and robotics, driving demand in manufacturing and industrial automation. As industries adopt more intelligent systems, the linear actuator market is set for sustained growth.

Understanding the Upstream and Downstream Industry Chains for Linear Actuators

To fully understand how the linear actuator market works, we need to look at both the upstream and downstream industry chains.

Upstream Components

The upstream components include essential raw materials like steel, aluminum, and plastics. These materials are crucial for creating strong and durable actuators. Through accurate manufacturing methods such as machining, assembling, and quality testing, these materials are converted into top-quality products.

Downstream Processes

On the other hand, the downstream processes focus on distribution channels that transport the final product to end-users in various sectors. Efficient distribution systems are essential in meeting customer demand in industries such as automotive and healthcare. The smooth operation of these channels guarantees timely delivery and ensures a steady supply of actuators to markets worldwide.

Impact of Supply Chain on Market Growth

A well-coordinated supply chain has a significant influence on market growth. When logistics are efficient and production is streamlined, lead times and costs can be reduced, leading to increased competitiveness in the market.

Companies that effectively manage their supply chains are better equipped to respond to changes in demand, which is crucial given the rising use of automation technologies. This efficiency not only boosts profits but also strengthens a company’s position in the rapidly changing linear actuator industry.

Trends Shaping the Linear Actuator Industry and Its Applications

The linear actuator industry is experiencing significant growth, driven by several trends across various sectors:

1. Robotics and Automation

The integration of automation technologies in robotics is creating new opportunities. Industries are increasingly adopting linear actuators to enhance precision and efficiency in automated systems. This trend is prevalent in automotive and manufacturing sectors, where automation reduces labor costs and increases productivity.

2. Healthcare Innovations

The demand for medical devices is rising, with linear actuators playing a critical role. From hospital beds to surgical robots, actuators offer precise control and movement essential for medical applications. This trend highlights the industry’s focus on improving healthcare delivery through technological advancements.

3. Manufacturing Advances

There is a growing push towards increased automation in manufacturing processes. Linear actuators are vital in this shift, facilitating tasks such as material handling and assembly operations. The agriculture sector also benefits from this trend, with mechanization leading to enhanced productivity and efficiency in farming activities.

4. Smart Home Integration

As consumers embrace smart home technologies, the demand for linear actuators rises. These components enable automated control of home features like adjustable furniture, window treatments, and security systems, offering convenience and energy efficiency.

These trends highlight the crucial role of linear actuators in modernizing industries through improved automation and technological integration.

Challenges in Developing and Customizing Linear Actuators

Limitations in Actuator Design

Design limitations present significant hurdles in the linear actuator market. As industries demand more compact and efficient systems, the challenge lies in developing actuators that meet these criteria while maintaining performance. The need for specialized designs that cater to unique applications often delays innovation, as it requires a delicate balance between creativity and practicality. These design limitations can significantly hinder the advancement of actuator technology.

Impact of Customization on Production Costs

Customization has both positive and negative effects. On one hand, tailored solutions provide a competitive edge. On the other hand, they also increase production costs.

When it comes to manufacturing custom actuators, there are two main reasons why costs go up:

- Higher expenses for materials: Customization often requires using specialized materials or components that are more expensive than standard ones. For instance, precast concrete is a customized material that significantly raises the cost.

- Increased labor costs: Custom actuators may require skilled workers or specialized machinery for precise engineering, leading to higher labor costs. A detailed breakdown of custom manufacturing costs can shed light on this aspect.

These cost factors can discourage companies from pursuing extensive customization. As a result, they may struggle to offer unique solutions to niche markets. However, research indicates that despite these challenges, the benefits of customization in terms of market differentiation and customer satisfaction can outweigh the increased production costs【10.1177/16878132241307065】.

It’s important to note that understanding the impact of customization on production costs is crucial for businesses aiming to balance between offering customized solutions and managing their expenses effectively.

Balancing Performance with Affordability

The search for high-performing actuators at affordable prices is ongoing. Manufacturers face the constant challenge of integrating advanced technologies, such as those seen in haptic experiences, without driving up costs. Cost-effective solutions often require compromises on performance attributes such as speed, load capacity, or durability. Striking a balance between these elements is crucial for sustaining growth within the competitive landscape of the linear actuator market.

These challenges highlight the complexity involved in pushing the boundaries of linear actuator technology while keeping products accessible and economically viable for a broad range of industries.

Geopolitical Factors Influencing the Global Linear Actuator Market

Geopolitical influences play a crucial role in shaping the manufacturing and sales channels of linear actuators. Global politics can significantly impact the availability and cost of raw materials, affecting production schedules and pricing strategies for manufacturers.

Key Aspects of Geopolitical Influences:

1. Trade Regulations

Trade policies are crucial in determining market dynamics. Tariffs, import/export restrictions, and bilateral agreements can either facilitate or hinder access to key markets. For instance, changes in U.S.-China trade relations have historically affected global supply chains across various industries, including linear actuators.

2. International Relations

Diplomatic relationships between countries influence industry growth by either promoting collaborative ventures or causing restrictions. Positive international relations often lead to joint ventures, technology exchanges, and investment opportunities that stimulate market expansion.

3. Regional Stability

Stability within a region directly impacts its attractiveness for business investments. Political unrest or economic uncertainty can deter potential investors and disrupt existing manufacturing operations. In contrast, stable regions like Germany and Japan offer secure environments conducive to technological advancements and industrial growth.

Understanding these geopolitical factors is vital for stakeholders aiming to navigate the complexities of the global linear actuator market successfully.

Market Segmentation: Types and Applications of Linear Actuators

The linear actuator market is characterized by a variety of technologies and applications, each suited to specific industry needs.

1. Electric Actuators

Electric actuators are favored for their precision and efficiency, making them ideal for automation processes in sectors like manufacturing and robotics. These actuators offer the advantage of low power consumption, aligning with the growing emphasis on energy-efficient solutions.

2. Hydraulic Actuators

Hydraulic actuators are renowned for their incredible power density, often used in heavy-duty applications such as aerospace and automotive industries. Their ability to generate high force makes them indispensable in situations where significant mechanical strength is required.

3. Pneumatic Actuators

Pneumatic actuators rely on air pressure, offering a cost-effective solution for applications requiring rapid movement and reliability. Industries such as food processing and packaging frequently deploy these actuators due to their simplicity and ease of maintenance.

Across various industries, linear actuators play crucial roles:

- Automotive: In car seat adjustments, throttle control, and advanced driver-assistance systems (ADAS).

- Aerospace: Used in flight control systems, landing gear operations, and cargo handling.

- Healthcare: Integral to medical devices like hospital beds and MRI machines.

- Construction: Essential in heavy machinery for positioning components accurately.

This segmentation highlights the diverse capabilities of linear actuators, underscoring their importance in modern industrial applications.

Linear Actuators in Robotics, Automation, and Healthcare Industries

Healthcare Industries

Linear actuators play a crucial role in various industries, including robotics, automation, and healthcare. Their ability to provide precise and controlled motion makes them essential components in these fields.

Linear Actuators in Robotics

In robotics, linear actuators are vital for the movement and positioning of robotic arms. They enable tasks that require high levels of accuracy, such as assembly, inspection, and packaging. With linear actuators, robotic arms can achieve smooth and controlled motion along a straight line, making them ideal for applications where space efficiency and reliability are critical.

Linear Actuators in Automation

The automation sector extensively uses linear actuators in manufacturing processes, assembly lines, and material handling systems. These devices automate repetitive tasks, leading to improved efficiency, precision, and reduced human error. Their versatility allows them to be integrated into various systems like conveyor belts, robotic grippers, and automated positioning systems. This integration contributes to the industry’s overall transition towards smart and automated solutions.

Linear Actuators in Healthcare

In healthcare settings, linear actuators find applications in medical devices and equipment such as hospital beds, prosthetics, and surgical robots. They facilitate important movements like adjusting bed height or positioning limbs in rehabilitation equipment. This functionality provides patients and healthcare providers with greater control and comfort.

As the demand for minimally invasive procedures and customizable medical solutions continues to rise, the significance of linear actuators in improving patient care and operational efficiency is expanding throughout the healthcare sector.

Global Insights into the Linear Actuator Market: Opportunities and Challenges

The global market for linear actuators presents numerous opportunities for growth, driven largely by emerging markets that are increasingly adopting automation technologies. Countries in Asia-Pacific, such as China and India, are seeing heightened demand due to rapid industrialization and the expansion of sectors like automotive and electronics. This region offers a fertile ground for investment, particularly as governments prioritize infrastructure development and smart manufacturing.

Opportunities for Growth:

- Emerging Markets: Rapid urbanization and industrial growth in countries like China and India bolster demand.

- Technological Advancements: Innovations in materials and design enhance actuator efficiency, appealing to industries seeking cost-effective solutions. This is part of the broader Fourth Industrial Revolution which is characterized by a range of new technologies that are blurring the lines between the physical, digital and biological worlds.

- Industry Diversification: Expanding applications across sectors including healthcare, aerospace, and agriculture create new avenues for growth. For instance, the integration of advanced actuators in these sectors is projected to significantly impact their operational efficiency and effectiveness as outlined in this recent study.

Potential Challenges:

- Supply Chain Disruptions: Manufacturers face challenges due to fluctuations in raw material availability and geopolitical tensions affecting trade routes.

- Cost Pressures: Balancing innovation with affordability remains a critical hurdle as consumers demand high-performance yet cost-effective solutions.

- Regulatory Compliance: Navigating diverse regulatory landscapes can be complex, especially for companies operating across multiple jurisdictions.

These factors influence the global linear actuator market, creating both opportunities and challenges for manufacturers.

U.S. Market Demand for Linear Actuators in Robotics and Automation

In the U.S., the demand for linear actuators in robotics and automation is rapidly increasing, driven by the need for greater efficiency, precision, and reliability in manufacturing and industrial processes.

As industries adopt more advanced automation technologies, linear actuators play a crucial role in enhancing robotic systems’ performance, enabling seamless movement for tasks like material handling, assembly, and precision control.

With the rise of Industry 4.0 and the expansion of smart factories, linear actuators are essential in driving innovation in robotics, particularly in areas like collaborative robots (cobots) and automated guided vehicles (AGVs).

The growing focus on reducing operational costs and increasing production efficiency is further fueling the demand for linear actuators across various U.S. sectors, including automotive, electronics, and food processing.

Germany’s Role in Advancing Linear Actuator Technologies

Germany is a global leader in the development and advancement of linear actuator technologies, especially in the fields of robotics and automation. The country’s strong engineering and manufacturing foundation, along with its focus on precision and innovation, has resulted in the creation of state-of-the-art linear actuators designed for high-performance applications.

Key Contributions of Germany in Linear Actuator Technologies

- Integration with Motion Control Systems: German companies are leading the way in combining linear actuators with advanced motion control systems, providing solutions that improve the accuracy and dependability of robotic systems.

- Industry 4.0 Implementation: Germany’s emphasis on Industry 4.0 and the automation of intricate manufacturing processes has fueled the use of linear actuators in smart production lines, leading to increased productivity and adaptability.

Germany’s expertise in mechanical engineering and industrial automation continues to influence the future of linear actuator technologies worldwide.

Japan’s Innovations in Linear Actuator Design and Application

Japan has long been recognized for its innovations in robotics and automation, and its contributions to the design and application of linear actuators are no exception. Japanese manufacturers are leading the charge in developing compact, high-performance actuators with advanced features like precise positioning and energy efficiency.

Applications of Linear Actuators in Japan

These actuators are used in a variety of applications, including:

- Industrial robotics

- Automated machinery

- Medical devices

- Consumer electronics

Impact of Japanese Advancements on Linear Actuators

Japanese advancements in miniaturization and precision engineering have made linear actuators an integral part of technologies such as:

- Robotic arms

- Smart manufacturing systems

- Autonomous vehicles

The country’s strong focus on research and development, combined with a deep understanding of automation needs, continues to drive innovation in the linear actuator market.

The Future of Linear Actuators: Automation, Robotics, and Energy Efficiency

The future of linear actuators is closely tied to advancements in automation, robotics, and energy efficiency. As industries push for more intelligent, efficient, and sustainable systems, linear actuators will play a central role in enabling high-precision movements and energy-efficient operations.

Advancements in Robotics

In robotics, the need for greater flexibility and adaptability in tasks such as assembly, packaging, and testing will drive the development of more advanced, customizable actuators.

Demand for Energy Efficiency

Additionally, the increasing demand for energy-efficient solutions in industries like manufacturing and logistics will encourage the adoption of actuators that consume less power while delivering superior performance.

Innovations in Materials

Innovations in materials, such as lightweight composites and energy-efficient motor technologies, will further enhance the capabilities of linear actuators, making them indispensable for the next generation of automation and robotic systems.

Ongoing Trend Toward Automation

With the ongoing trend toward automation and smart systems, linear actuators will continue to evolve, playing a critical role in shaping the future of numerous industries.

Competitive Landscape in the Linear Actuator Industry

The linear actuator industry is characterized by the presence of several major players who are shaping its competitive dynamics. Key companies include:

-

Bosch Rexroth AG —— Germany

-

Emerson Electric Co. —— USA

-

HepcoMotion Ltd. —— UK

-

Kollmorgen Corporation —— USA

-

LINAK —— Denmark

-

Oriental Motor Co. Ltd —— Japan

-

Parker Hannifin Corporation —— USA

-

Rockwell Automation —— USA

-

Thomson Industries Inc. —— USA

-

Tolomatic Inc. —— USA

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Linear Actuator Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Linear Actuator Market is still very competitive because of new technologies and a growing need for automation in many industries. Companies that are good at coming up with new ideas and adapting to change have a great chance to grow in this changing environment.

The linear actuator market is expected to grow significantly due to advancements in automation, sustainability, and smart technologies. Electric linear actuators, projected to grow at a 7.2% CAGR through 2033, will dominate because of their energy efficiency and smooth integration with Industry 4.0 systems. Emerging markets, especially in Asia-Pacific, are expected to drive this growth, supported by rapid industrialization and the increasing demand for precision in manufacturing.

Global Linear Actuator Market Report (Can Read by Free sample) – Table of Contents Chapter 1: Linear Actuator Market Analysis Overview Competitive Forces Analysis (Porter’s Five Forces) Strategic Growth Assessment (Ansoff Matrix) Industry Value Chain Insights Regional Trends and Key Market Drivers Linear Actuator Market Segmentation Overview Chapter 2: Competitive Landscape Global Linear Actuator players and Regional Insights oKey Players and Market Share Analysis Sales Trends of Leading Companies oYear-on-Year Performance Insights Competitive Strategies and Market Positioning oKey Differentiators and Strategic Moves Chapter 3: Linear Actuator Market Segmentation Analysis Key Data and Visual Insights oTrends, Growth Rates, and Drivers Segment Dynamics and Insights oDetailed Market Analysis by Segment Chapter 4: Regional Market Performance Consumer Trends by Region oHistorical Data and Growth Forecasts Regional Growth Factors oEconomic, Demographic, and Technological Impacts Challenges and Opportunities in Key Regions Regional Trends and Market Shifts Key Cities and High-Demand Areas Chapter 5: Linear Actuator Emerging and Untapped Markets Growth Potential in Secondary Regions oTrends, Challenges, and Opportunities Chapter 6: Product and Application Segmentation Product Types and Innovation Trends Application-Based Market Insights Chapter 7: Linear Actuator Consumer Insights Demographics and Buying Behaviors oTarget Audience Profiles Chapter 8: Key Findings and Recommendations Summary of Linear Actuator Market Insights Actionable Recommendations for Stakeholders

Chapter 1: Linear Actuator Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Linear Actuator MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Linear Actuatorplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Linear Actuator Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Linear Actuator Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Linear Actuator Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Linear Actuator Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the current market value and growth projection for linear actuators?

The linear actuator market is growing rapidly. It is expected to increase significantly in value because of the rising demand in industries like robotics, automation, and healthcare.

What are the key components of the supply chain for linear actuators?

The supply chain for linear actuators includes:

- Upstream components such as raw materials and production processes

- Downstream processes that involve distribution channels to end-users

Both upstream and downstream components have an impact on overall market growth.

What trends are currently shaping the linear actuator industry?

Current trends driving demand in the linear actuator industry include:

- Advancements in automation technologies

- Integration of smart home devices

- Increasing use in medical applications, particularly in robotics and healthcare

What challenges do manufacturers face in customizing linear actuators?

Manufacturers face several challenges when customizing linear actuators, such as:

- Design limitations

- High production costs associated with customization

- The need to balance performance with affordability

How do geopolitical factors influence the global linear actuator market?

Geopolitical factors have a major impact on the global linear actuator market. Trade regulations and international relations play a key role in shaping manufacturing capabilities and sales channels. These factors also affect regional stability and industry growth.

What types of linear actuators are available on the market, and what are their applications?

There are several types of linear actuators available on the market:

- Electric Actuators: These use electrical energy to create motion and are commonly found in applications where precise control is required.

- Hydraulic Actuators: These rely on fluid power to generate movement and are often used in heavy machinery or industrial settings.

- Pneumatic Actuators: These operate using compressed air and are typically employed in applications where quick, repetitive motion is necessary.

These actuators find applications in various industries such as:

- Automotive: Used in vehicle assembly lines for tasks like lifting, pushing, or pulling components.

- Aerospace: Employed in aircraft manufacturing for precise positioning of parts during assembly.

- Manufacturing: Utilized in factories for automated processes requiring linear movement.

- Robotics: Integrated into robotic systems for achieving specific linear motions.

The versatility of linear actuators makes them suitable for a wide range of applications across different sectors.