Mechanical Control Cables Market Estimated at $11.06 Billion by 2025: Demand Surging in China, Italy, and the U.S.

- Last Updated:

Mechanical Control Cables Market: Q1 and Q2 of 2025 Analysis

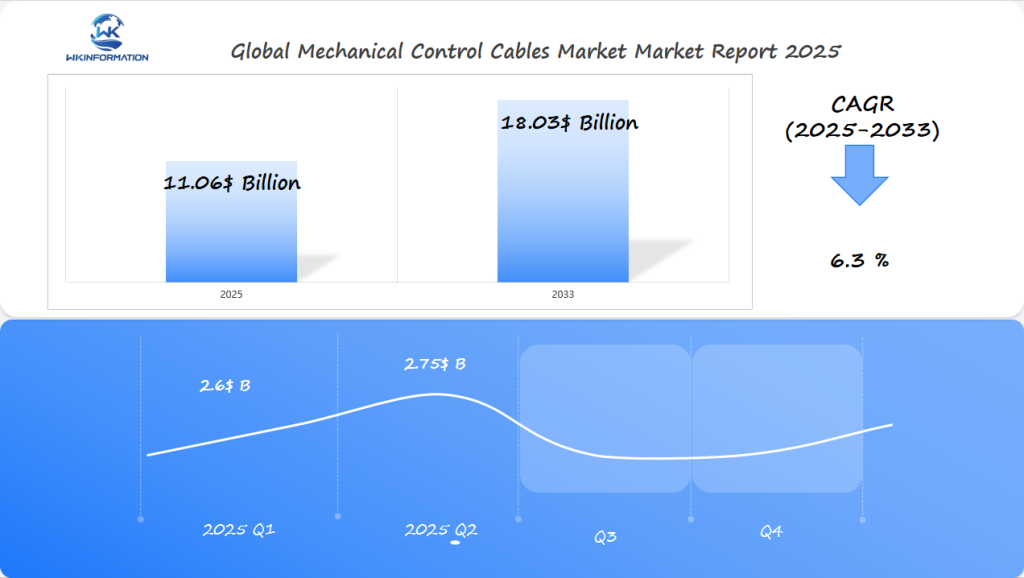

The Mechanical Control Cables market is expected to reach $11.06 billion by 2025, with a CAGR of 6.3% during the period from 2025 to 2033. In Q1 2025, the market size is forecast to be $2.6 billion, with growth continuing into Q2, reaching $2.75 billion. These cables are integral to a wide variety of applications, including automotive, aerospace, and industrial machinery, due to their durability and flexibility. China, Italy, and the U.S. are the largest consumers of mechanical control cables.

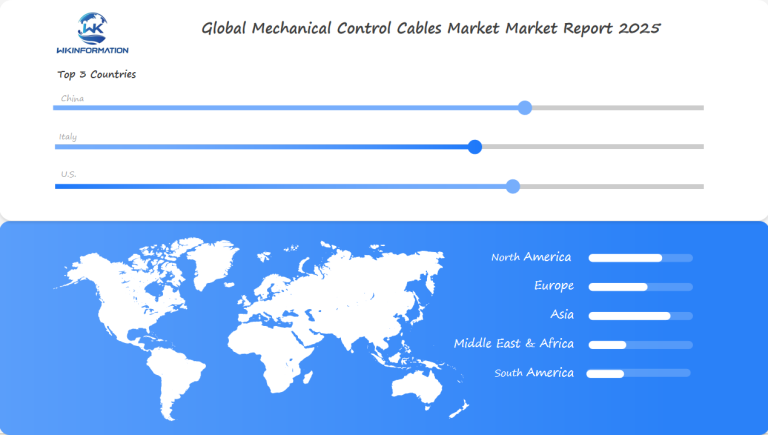

China remains a dominant player in manufacturing, while Italy and the U.S. focus on applications in the automotive and industrial sectors. As industries increasingly rely on automation and precise control mechanisms, the market for mechanical control cables will continue to expand, with a notable surge in demand for specialized cables for electric and hybrid vehicles. Growth in the automotive sector, particularly in electric vehicles, will further bolster demand in the coming years.

Key Takeaways

- The mechanical control cables market is expected to reach $11.06 billion by 2025.

- China, Italy, and the U.S. are driving global market expansion.

- The automotive and industrial sectors are the primary growth engines.

- Technological innovations are enhancing cable performance.

- Increasing industrial automation is supporting market development.

Mechanical Control Cables Market Upstream and Downstream Industry Chain Structure

The mechanical control cables industry is a complex web of processes and players. It starts with getting raw materials, goes through detailed making, and ends with getting the product to customers.

Upstream: Getting Raw Materials

Getting raw materials is key at the start of the chain. Important materials include:

- High-grade steel wires

- Specialized polymer coatings

- Precision metal alloys

- Corrosion-resistant lubricants

Manufacturing Process: Creating Mechanical Control Cables

Creating mechanical control cables involves many steps. Engineers use careful design to make sure the cables work well and last long. These steps include:

- Wire drawing and preparation

- Core cable assembly

- Protective coating application

- Quality control testing

Downstream: Where the Cables Go

The end of the chain is where the cables go to different industries. Automotive, aerospace, marine, and industrial machinery sectors are the main users. They drive the market.

Importance of Distribution: Getting Cables to Customers

Getting the cables to customers is crucial. It connects makers with buyers worldwide. This ensures new tech reaches various industries smoothly.

2025 Trends Influencing Mechanical Control Cables Markets

The mechanical control cables market is changing fast. New technologies are leading the way. These changes are making big impacts on how these parts are made and used in many fields.

Changes in Manufacturing and Applications

There are big changes in how these cables are made and used. Companies are working on making cables lighter and stronger. They need to work well in tough conditions and be very precise.

- Advanced materials like high-strength composites are replacing traditional metal cables

- Smart sensing technologies are being integrated into cable systems

- Increased demand for miniaturization in industrial and automotive applications

Key Areas of Technological Impact

There are three main areas where technology is making a big difference:

- Automotive Integration: Next-generation vehicles need better control systems

- Industrial Automation: Cables for complex robotic tasks

- Aerospace Engineering: Cables that are light but very strong

Innovations Driving Market Growth

The world is seeing a lot of new ideas in mechanical control cables. Researchers are making cables that are more flexible, lighter, and better at sending signals. These changes will help the market grow a lot in many different areas.

Barriers and regulatory issues affecting Mechanical Control Cables

The mechanical control cables industry faces big challenges from regulations. These rules shape how the market works and what products can be made. Safety standards and compliance rules are complex for makers and suppliers in various places.

How Regulatory Hurdles Affect Companies

Regulatory hurdles affect how companies enter markets and innovate. Here are some ways:

- Strict safety rules in cars and planes

- Global standards for cable quality and strength

- Need for quality certifications for cables

- Rules for using eco-friendly materials

Different places have their own rules. The U.S. has tough testing rules, while the EU cares about green materials and how well things work. These rules make it hard for companies to grow worldwide.

Industry standards are key in making and designing cables. Makers spend a lot on:

- Research to keep up with new standards

- Testing and getting certifications

- Improving quality all the time

- Keeping detailed records and tracking

Dealing with complex rules means makers need to be flexible and creative in making cables. Companies that get past these hurdles can become leaders and grow their market share.

Geopolitical risks and supply chain pressures for Mechanical Control Cables

The mechanical control cables market is facing big challenges from global politics. These challenges affect how goods are made and moved around the world. Companies and suppliers need to find new ways to manage these risks.

Supply chain problems come from several key areas:

- Trade tensions between big manufacturing countries

- Changes in regional economic policies

- Shortages of raw materials

- New rules for making things internationally

Companies must find strong ways to deal with these issues. Spreading out where they get their supplies is a key strategy to avoid market ups and downs.

Uncertainty in the global economy adds more trouble for makers of mechanical control cables. They are spending a lot on tools to predict and prevent problems.

Companies that plan well for risks can avoid big problems. They use:

- Full maps of their supply chains

- Planning for different scenarios

- Flexible ways to buy things

- High-tech systems to watch their supply chains

By tackling geopolitical risks head-on, makers of mechanical control cables can keep their production steady and stay competitive.

Type-specific breakdown in the Mechanical Control Cables market

The mechanical control cables market has many types of cables. These cables are key in various industries. There are mainly three types: push-pull, pull-pull, and push-push cables. Each type has special features for different needs and challenges.

Knowing about cable types is important for market analysis and choosing products. Companies work hard to make cables that fit complex industrial needs.

Push-Pull Cables: Versatile Performance Solutions

Push-pull cables are a basic type used in many places. They are great at moving mechanical force over different distances and angles. They have:

- High flexibility in mechanical power transmission

- Adaptable design for complex routing requirements

- Optimal performance in compact mechanical systems

Pull-Pull Cables: Precision Transmission Mechanisms

Pull-pull cables are all about precise linear motion control. They are getting more popular in automation and robotics. They have:

- Enhanced accuracy in force transmission

- Reduced friction compared to traditional mechanical links

- Consistent performance under repetitive stress

Push-Push Cables: Specialized Mechanical Interfaces

Push-push cables are great for tough mechanical settings. They are especially useful in aerospace and medical devices where exact control is needed.

The mechanical control cables market is growing fast. New innovations keep pushing the market forward. This growth is seen across many industries.

Exploring major applications of Mechanical Control Cables in various sectors

Mechanical control cables are key to making industries more efficient. They help control complex systems with great precision. This meets the needs of many industries.

These cables are very adaptable in different industries. They are made to meet high standards in several sectors.

Automotive Industry Innovations

Car makers use mechanical control cables for important functions. These cables control:

- Throttle control mechanisms

- Transmission shift linkages

- Emergency brake systems

- Clutch and accelerator operations

Aerospace and Defense Requirements

In aerospace and defense, precision is crucial. These cables must work well in harsh conditions and be very reliable.

| Sector | Primary Applications | Performance Criteria |

| Military Aircraft | Flight control systems | High durability, temperature resistance |

| Commercial Aviation | Landing gear mechanisms | Precision movement, low friction |

Marine Industry Deployment

Marine environments require durable mechanical control cables. These cables must be resistant to corrosion and perform effectively in harsh conditions. They are utilized in vessels for steering and engine control.

Industrial Machinery Applications

Manufacturing and industrial machinery use these cables for precise control. They help in robotic systems, assembly lines, and heavy equipment.

The development of mechanical control cables is key to improving industries worldwide. They help make systems more efficient and advanced.

Global Mechanical Control Cables market segmented by region

The mechanical control cables market varies greatly across different regions. Each area has its own market dynamics and growth potential. Understanding these regional markets is key to grasping the global scene.

Geographical segmentation shows different patterns of market growth in major global areas. Companies are now focusing on these regional differences to improve their strategies.

North American Market Insights

North America is a strong market for mechanical control cables. It has advanced industrial setups and big tech investments. The region’s automotive and aerospace sectors are driving the demand for advanced cable solutions.

- Strong automotive manufacturing base

- High technological innovation

- Substantial industrial automation investments

European Market Dynamics

European markets are experiencing rapid growth in mechanical control cables. Countries such as Italy and Germany are at the forefront of this growth, with their robust manufacturing industries playing a crucial role in this expansion.

Asia-Pacific Growth Trajectory

Rapid industrialization and increasing manufacturing capabilities are driving significant market opportunities in the Asia-Pacific region. China’s automotive sector is crucial for cable technology advancements.

- Expanding manufacturing capabilities

- Growing technological infrastructure

- Increasing industrial investments

The Rest of the World segment offers great potential for mechanical control cable makers. Developing economies are adopting advanced cable technologies in various industries.

China's automotive sector powering Mechanical Control Cable demand

The Chinese market is a key player in mechanical control cables, thanks to its booming automotive industry. New technologies and strong market drivers are driving growth in cable production and demand across various sectors.

Factors shaping the mechanical control cables market in China:

- Exponential growth in vehicle production

- Advanced automotive manufacturing technologies

- Strategic government industrial development policies

- Increasing investment in research and development

Domestic car makers are investing heavily in mechanical control cable technology to improve car performance and reliability. The Chinese automotive industry is leading the world in adopting high-quality cable solutions. These solutions enhance mechanical efficiency and safety standards.

Market research indicates that China’s mechanical control cables market is poised for significant growth. Companies are focused on developing lighter, superior cables that comply with stringent international standards. This strategy enables them to remain competitive both locally and globally.

Partnerships between car manufacturers and cable technology firms are accelerating innovation. These collaborations are resulting in the creation of advanced cable solutions that address complex engineering challenges in modern vehicles.

China’s car industry is undergoing rapid transformation, creating new opportunities for mechanical control cable manufacturers. This positions China as a leading player in cable technology and innovation on a global scale.

Italy's mechanical engineering firms driving cable applications

The Italian market is a leader in mechanical engineering. It’s known for making advanced mechanical control cables for industries. Italian companies are setting new standards in cable technology across many sectors.

Strengths of Italian Mechanical Engineering in Cable Design

Italian mechanical engineering is strong in cable design because of:

- Advanced precision engineering techniques

- High-quality material selection

- Innovative cable manufacturing processes

- Customized solutions for complex industrial requirements

Specialized Skills of Italian Makers

Italian makers are known for their specialized mechanical control cables. They meet tough performance standards. Their skills cover important areas like car systems and precise machinery.

Strategic Approach of Italian Mechanical Engineering Firms

Italian mechanical engineering firms follow a smart plan:

- They keep researching and developing

- They invest in the latest manufacturing tech

- They work with global industrial partners

- They focus on high-performance cable solutions

These companies do more than make cables. They create full solutions for tough mechanical control problems in many industries.

U.S. industrial automation boosting cable usage

The U.S. market is undergoing significant transformations in industrial automation. This shift is creating a substantial demand for mechanical control cables. The emergence of new manufacturing technologies is driving the need for advanced cable solutions capable of handling intricate tasks.

Factors driving the use of mechanical control cables in the U.S.

Several key factors are contributing to the increased adoption of mechanical control cables in the United States:

- Advanced robotic manufacturing systems

- Smart factory infrastructure development

- Precision control mechanisms in high-performance machinery

Investment in cable technologies

Companies are investing heavily in innovative cable technologies designed to withstand harsh industrial environments. Performance, durability, and reliability are paramount considerations for engineers selecting mechanical control cables.

The ongoing digital transformation within U.S. manufacturing presents new opportunities for innovation in mechanical control cables. Companies are developing customized cables that seamlessly integrate with cutting-edge automation technologies, ensuring optimal performance and enhanced efficiency.

Outlook on Mechanical Control Cables market growth

The mechanical control cables market is set to grow a lot in the next few years. This growth will come from new technologies and more use of automation. The market is expected to grow steadily in many areas, especially in cars, planes, and machines.

Key areas of market development include:

- Increased demand for precision engineering solutions

- Rising industrial automation requirements

- Technological innovations in cable design

- Expansion of manufacturing capabilities

Looking ahead, we see important trends. Emerging technologies are changing how we use mechanical control cables. This opens up new chances for makers and users. The market will keep growing thanks to more money spent on research and development.

Companies are working on making better mechanical control cables. They want to meet the needs of today’s industries. The forecast says we’ll see more innovation, especially in cables that are light, strong, and precise. With smart investments and new tech, the mechanical control cables market will keep growing. This will bring big chances for everyone in the industry.

Competitive positioning in the Mechanical Control Cables industry

The mechanical control cables market is very competitive. Many key players are working hard to grow. They keep coming up with new ideas to stay ahead.

Key Players:

-

Cablecraft Motion Controls LLC – United States

-

Loos & Co., Inc. – United States

-

Madison Company – United States

-

Teleflex Marine – United States

-

Morse Controls – United States

-

HWC Inc. (Houston Wire & Cable Company) – United States

-

Sava Industries, Inc. – United States

-

WireCo WorldGroup Inc. – United States

-

Lexco Cable Mfg. – United States

-

CMA/Flodyne/Hydradyne – United States

Top companies are using several important strategies:

- Investing in research and development

- Expanding global manufacturing capabilities

- Forming strategic partnerships

- Enhancing product performance and reliability

New players are shaking things up by offering affordable, high-tech cables. The competitive landscape is full of innovation and smart moves.

Big players are focusing on making their own parts and improving technology. They create special cables for cars, planes, and factories. This helps them stand out from others.

The industry is getting more competitive because of:

- Rapid technological adaptation

- Customization of cable solutions

- Sustainable manufacturing practices

- Global supply chain optimization

Companies that do well in the mechanical control cables market will be quick, tech-savvy, and strategic.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Mechanical Control Cables Market Report |

| Base Year | 2024 |

| Segment by Type |

· Push-Pull Cables · Pull-Pull Cables · Push-Push Cables |

| Segment by Application |

· Automotive Industry · Aerospace and Defense · Marine Industry · Industrial Machinery · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Mechanical control cables are key to making industries more efficient. They help machines work better and more precisely. This makes operations more reliable and efficient in complex settings.

These cables also make workplaces safer. They help avoid mistakes and improve safety standards. This is crucial in industries like cars, planes, and ships.

Modern mechanical control cables offer more than just basic functions. They use new materials and designs. This makes them last longer, need less upkeep, and perform better.

The development of mechanical control cables is vital for industry growth. As manufacturing gets more complex, these cables will keep improving. They ensure safe and reliable operations in many fields.

Global Mechanical Control Cables Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Mechanical Control Cables Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Mechanical Control Cables Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Mechanical Control Cables Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Mechanical Control Cables Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Mechanical Control Cables Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Mechanical Control Cables Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Mechanical Control Cables Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the estimated market value of Mechanical Control Cables by 2025?

The Mechanical Control Cables market is expected to reach $11.06 billion by 2025. This growth is primarily driven by countries such as China, Italy, and the United States.

What are the main types of Mechanical Control Cables?

There are mainly three types: push-pull, pull-pull, and push-push cables. Each is made for different uses in various industries.

Which industries primarily use Mechanical Control Cables?

Industries such as automotive, aerospace, marine, and industrial machinery utilize these cables. Each industry has its specific requirements and applications.

What factors are driving the growth of Mechanical Control Cables?

Growth is fueled by tech advancements, more automation, and demand in the auto sector. Also, the need for precise control in making things is a big factor.

How are geopolitical risks affecting the Mechanical Control Cables market?

Geopolitical risks affect the market through trade issues, economic policies, and global events. These can disrupt production, distribution, and prices of Mechanical Control Cables.

What regulatory challenges exist in the Mechanical Control Cables industry?

The industry faces challenges like industry standards, safety rules, and compliance. These vary by region and affect how companies enter the market and develop products.

Which regions are showing the most significant growth in Mechanical Control Cables?

North America, Europe, Asia-Pacific, and especially China are growing fast. Each region has its own market trends and opportunities.

How Mechanical Control Cables are contributing to industrial efficiency?

These cables enhance machine performance, provide precise control, and create safer work environments. They also enable advanced industrial capabilities across various industries.

What role does China play in the Mechanical Control Cables market?

China plays a crucial role in the growth of the Mechanical Control Cables market. The country’s thriving automotive industry and increasing vehicle production are major factors driving this growth. Additionally, government policies in China are also supportive of the industry, further contributing to its expansion.

How are technological advancements impacting Mechanical Control Cables?

New technology leads to better cable designs, improved performance, and longer life. It also opens up new uses in different industries.