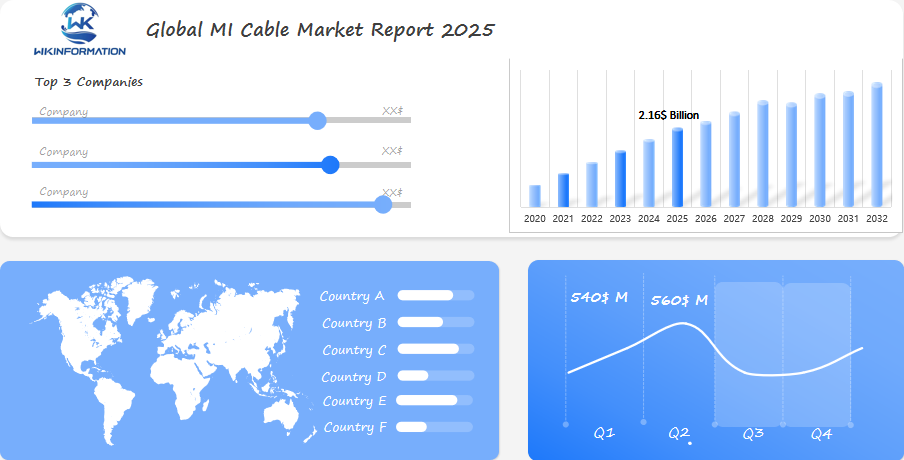

MI Cable Market Forecast for Q1 and Q2 of 2025

The global demand for MI Cable is expected to be valued at USD 2.16 billion in 2025, growing at a CAGR of 5.13% from 2025 to 2033. Flexible mineral-insulated cables are used in applications that require high-performance and safety, such as industrial machinery, energy systems, and building infrastructure. These cables are known for their resistance to extreme temperatures and harsh environments, making them ideal for use in industries like oil and gas, power generation, and construction. By the end of Q1 2025, the market size is estimated to be approximately USD 540 million, driven by increasing construction activities and demand for energy-efficient solutions in industrial sectors. By Q2 2025, the market could grow to around USD 560 million, with strong demand from the U.S., China, and Germany.

This market’s growth is expected to be supported by regulatory requirements for fire-resistant and durable materials in industrial and commercial applications.

Key Takeaways

- The U.S., China, and Germany lead the global expansion of the MI cable market.

- MI cables are crucial for ensuring electrical safety in industrial and power applications.

- The MI cable market is projected to reach US$ 2.16 billion by 2025.

- Construction and infrastructure projects drive market growth.

- These nations are pioneering innovations in electrical safety and reliability.

Overview of the MI Cable Market

The flexible mineral insulated (MI) cable market is a crucial segment in the electrical industry, known for its durability and reliability in high-temperature environments. As industries seek safer and more efficient power distribution solutions, the demand for MI cables has surged, making it a key area of focus.

MI Cable Size and Growth Projections

The global demand for MI Cable was valued at USD 2.16 Billion in 2025, growing at a CAGR of 5.13% between 2025 and 2033. This growth is driven by increasing infrastructure projects and the need for advanced electrical systems.

Technical Specifications and Material Insights

MI cables are constructed using copper rods as conductors and magnesium oxide as the insulating material, providing exceptional thermal stability. The table below outlines key specifications and materials:

| Specification | Details |

|---|---|

| Conductor Material | Copper Rods |

| Insulation | Magnesium Oxide |

| Maximum Operating Temperature | Up to 1050°C |

| Applications | Industrial, Power Plants, High-Temperature Environments |

These technical advancements ensure MI cables meet stringent safety standards, making them ideal for critical applications. As MI Cable Market evolves, ongoing innovations will further enhance their performance and adaptability.

Technological Advancements Driving Cable Innovation

Technological advancements are revolutionizing the design and manufacturing of electrical cables, particularly in the mineral insulated sector. These innovations are not only enhancing durability but also introducing new levels of flexibility and intelligence to cable systems.

Emerging Manufacturing Techniques

Modern manufacturing techniques are playing a pivotal role in improving the efficiency and safety of cable production. For instance, advanced extrusion processes and precision winding technologies are enabling the creation of cables with tighter tolerances and superior performance characteristics.

| Advancement | Improvement | Example |

|---|---|---|

| Smart Monitoring Systems | Real-time diagnostics and fault detection | Integration of temperature sensors for predictive maintenance |

| Nano-material Coatings | Enhanced durability and fire resistance | Application in high-temperature industrial environments |

| Automated Insulation Processes | Consistent insulation quality and faster production | Reduced human error and increased output capacity |

These technological breakthroughs are not only optimizing production but also enabling the development of cables that can withstand extreme conditions while maintaining high performance standards. The integration of intelligent features, such as real-time monitoring and fault detection, is setting new benchmarks for reliability and safety in the industry.

Key Market Drivers in the U.S., China & Germany

The expansion of the MI cable market in the U.S., China, and Germany is driven by a combination of industrial advancements, infrastructure development, and stringent safety regulations. These nations are at the forefront of innovation, creating a dynamic environment that fuels market growth.

Industrial Automation and Safety Enhancements

Industrial automation has become a cornerstone of modern manufacturing, significantly boosting the demand for high-performance electrical solutions. In the U.S., industries like automotive and aerospace are increasingly adopting automated systems, requiring reliable power transmission solutions. Similarly, China’s rapid industrialization is driving the need for advanced electrical systems that ensure both efficiency and safety.

Germany, a global leader in industrial automation, is pushing the boundaries with smart manufacturing technologies. The integration of intelligent monitoring systems in MI cables allows for real-time diagnostics, enhancing predictive maintenance capabilities and operational reliability.

Infrastructure Investments and Regulatory Initiatives

Substantial infrastructure investments in power transmission and transportation projects are another key driver. The U.S. is focusing on upgrading its aging power grid, while China is expanding its high-speed rail network. These projects require durable and high-temperature-resistant electrical solutions, making MI cables an ideal choice.

Regulatory measures in these countries further accelerate market growth. Stricter safety standards for electrical systems in industrial and commercial sectors have increased the demand for MI cables, known for their exceptional performance in harsh environments.

These factors collectively create a robust ecosystem for the MI cable market, driving innovation and ensuring sustained growth in the coming years.

Industrial Applications and Safety Standards for MI Cables

Mineral-insulated (MI) cables are pivotal in various industrial settings due to their exceptional fire resistance and ability to perform under extreme temperatures. These qualities make them indispensable in sectors where safety and reliability are paramount.

Fire Resistance and High-Temperature Performance

MI cables are renowned for their fireproof properties, primarily due to their magnesium oxide insulation. This insulation ensures that the cables can withstand intense heat without compromising their electrical integrity, making them ideal for high-risk environments.

| Feature | Specification |

|---|---|

| Fire Resistance | Withstands intense heat without damage |

| Maximum Temperature | Operates effectively up to 1050°C |

| Applications | Petrochemical plants, power generation, construction |

These cables are used in petrochemical plants to handle hazardous materials, in power generation for reliable energy transmission, and in construction for fire-safe electrical systems. Their ability to maintain performance under high temperatures aligns with stringent regulatory standards, ensuring safety and efficiency across industries.

Market Segmentation and Data-Driven Analysis

Understanding the diverse segments within the MI cable industry is crucial for grasping its growth dynamics. By categorizing MI Cable based on cable types, sheath materials, and end-user industries, stakeholders can better tailor their strategies to meet specific demands.

Cable Type and Material Composition

The MI cable market is segmented into single-core and twin-core cables, each catering to different applications. Single-core cables are ideal for high-temperature environments, while twin-core cables offer enhanced flexibility. The choice of sheath materials, such as copper or stainless steel, significantly impacts durability and application suitability.

End-User Industries and Energy Demand

Industries like energy and manufacturing drive the demand for MI cables due to their reliability in extreme conditions. Data-driven insights reveal that the energy sector alone accounts for a substantial portion of MI cable usage, underlining the need for tailored solutions to meet specific industry needs.

Segmentation for Strategic Innovation

By analyzing MI Cable segments, companies can identify opportunities for innovation. For instance, focusing on core materials can lead to advancements in thermal stability, directly benefiting high-energy applications. This targeted approach ensures that products meet the evolving needs of various sectors.

Such segmentation not only aids in understanding MI Cable dynamics but also guides the development of innovative solutions, ensuring sustained growth and adaptability in the MI cable industry.

Regulatory Landscape and Compliance Considerations

Regulatory standards play a crucial role in shaping the product design and installation processes of MI cables. In the U.S., Europe, and China, stringent safety regulations ensure that these cables meet specific criteria for fire resistance and thermal stability. For instance, the National Electric Code (NEC) in the U.S. sets strict guidelines for electrical systems, directly influencing how MI cables are constructed and implemented.

Construction codes and electrical regulations are fundamental in addressing safety risks. These frameworks serve as solutions to potential hazards by mandating rigorous testing and certification processes. For example, MI cables must pass intense heat resistance tests before being approved for use in high-risk industrial environments. Such measures ensure that gas emission restrictions and other environmental safety requirements are met, reducing the risk of accidents and environmental damage.

In key MI Cable Market, compliance measures are strictly enforced. In the U.S., MI cables must adhere to NEC guidelines, while in Europe, they must comply with the International Electrotechnical Commission (IEC) standards. These regulations not only enhance safety but also drive innovation, encouraging manufacturers to develop more reliable and efficient construction solutions.

By adhering to these regulations, industries ensure the safe and efficient use of MI cables, maintaining high standards of electrical safety and environmental responsibility.

Competitive Analysis of the MI Cable Market

The MI Cable market is gaining momentum due to its use in high-temperature and fire-resistant applications across industries such as construction, power generation, and oil and gas. Thermal Resources Management is a key player in MI Cable Market, providing MI Cables that offer exceptional thermal resistance and safety features for high-risk environments. AEI Cables offers a broad range of mineral-insulated cables that are ideal for industrial and commercial applications, providing enhanced performance in extreme conditions. Znergy Cable and ZMS Cable are notable competitors, focusing on the design and production of MI Cables for use in electrical systems that require high reliability, especially in hazardous locations. Simsheng Cable and Jiangsu Shangshang Cable Group offer cost-effective solutions for large-scale projects in various sectors, including construction and manufacturing. Haohui Cable, Xingsheng Cable, Southern Flame, and Shandong New Luxing Cable are also important players in the market, producing flexible mineral-insulated cables that meet safety standards and are suitable for use in fire-sensitive and hazardous environments.

As industries increasingly prioritize safety and durability, the demand for MI Cables is expected to grow, with these companies leading the charge in providing high-quality and fire-resistant solutions.

Regional Insights with a Focus on the United States

The United States is leading the charge in the regional growth of the MI cable industry, driven by significant infrastructure investments and stringent safety regulations. According to recent MI Cable Market reports, North America is expected to account for a substantial share of the global forecast, with the U.S. at the forefront.

Key factors driving this growth include the nation’s focus on upgrading its power grid and expanding industrial automation. The increasing demand for reliable power transmission solutions in sectors like energy and manufacturing has further accelerated this trend. Regional manufacturing advancements and compliance with strict regulatory policies are also contributing to the market’s robust expansion.

The U.S. MI Cable Market is projected to grow at a CAGR of 6.8% through 2031, aligning with global forecasts. This growth is supported by the rising need for high-performance electrical systems capable of withstanding extreme conditions. Comparatively, the U.S. market dynamics mirror global trends but with a stronger emphasis on innovation and regulatory compliance.

In conclusion, the U.S. plays a pivotal role in shaping the future of the MI cable industry, with a promising outlook driven by technological advancements and strategic initiatives.

Innovative Design and Manufacturing Techniques

Modern manufacturing techniques have revolutionized the production of MI cables, integrating intelligent features that enhance performance and safety. These advancements ensure that MI cables meet the growing demands of industrial applications.

Role of Copper Conductors and Wire Construction

Copper conductors are at the heart of MI cable design, offering exceptional thermal stability and conductivity. High-quality wire construction ensures reliable power transmission, making these cables ideal for high-temperature environments.

Integration of Temperature Monitoring Systems

Intelligent temperature monitoring systems provide real-time diagnostics, enhancing operational safety and predictive maintenance. These systems help prevent overheating, ensuring continuous performance in critical applications.

Benefits of Stainless Steel Sheaths

Stainless steel sheaths offer superior durability and corrosion resistance. This makes MI cables suitable for harsh industrial environments, ensuring long-term reliability and minimal maintenance.

Applications of Heating Cable Features

Heating cable features are particularly beneficial in petrochemical plants and power generation, where consistent heat management is crucial. These applications highlight the versatility and efficiency of advanced MI cables.

Future Trends and Forecasts of the MI Cable Market

The MI cable market is poised for significant growth, driven by advancing technologies and rising demand for high-performance solutions. As industries evolve, the focus on safety, efficiency, and innovation will shape the future landscape.

Emerging Opportunities and Market Forecasts

Emerging opportunities in the MI cable market are largely spurred by advancements in insulation and heating technologies. These innovations are expected to drive market expansion, particularly in sectors requiring reliable high-temperature solutions.

| Trend | Impact |

|---|---|

| Advanced Insulation Materials | Enhanced thermal stability and durability |

| Smart Heating Systems | Improved energy efficiency and real-time monitoring |

| Cost-Effective Manufacturing | Increased accessibility for new market players |

Cost dynamics will play a crucial role in shaping future strategies. As manufacturing becomes more efficient, the entry of new players is expected to increase, fostering competition and innovation.

Technological developments, such as intelligent monitoring systems, will continue to enhance performance and safety. These advancements, coupled with strategic initiatives, will drive the MI Cable Market toward sustained growth and adaptation to industry needs.

Best Practices for Enhanced Electrical Safety

Electrical safety is paramount in ensuring the reliability and efficiency of power distribution systems. Implementing best practices is essential to minimize risks and optimize system performance. This section outlines key guidelines for selecting the right cable type and size, integrating systems effectively, and maintaining electrical integrity.

Selecting the appropriate cable type and size is critical. The cable must match the specific demands of the application, considering factors like voltage, current, and environmental conditions. For instance, in high-temperature environments, cables with superior thermal stability are essential to prevent overheating and ensure continuous operation.

System integration is another crucial aspect. Properly integrating electrical components ensures seamless communication and operation. Techniques such as real-time monitoring and predictive maintenance can enhance safety by identifying potential issues before they escalate, thus reducing downtime and improving overall efficiency.

Maintenance and installation practices play a vital role in sustaining safety standards. Regular inspections and adherence to industry protocols can prevent failures and extend the lifespan of electrical systems. Training personnel on the latest safety procedures further reinforces a culture of safety within organizations.

Adhering to industry standards is non-negotiable. Compliance with regulations ensures that systems meet established safety benchmarks, reducing the risk of accidents. For example, following the National Electric Code (NEC) guidelines in the U.S. is fundamental for maintaining electrical safety across various applications.

Case studies highlight the impact of these best practices. In one instance, a manufacturing plant implemented advanced cable monitoring systems, which led to a significant reduction in operational hazards. This example underscores the importance of integrating proven solutions to enhance safety outcomes.

By focusing on optimal cable selection, robust system integration, and stringent maintenance protocols, industries can achieve higher levels of electrical safety. These practices not only protect assets but also contribute to overall operational efficiency and reliability.

| Report Metric | Details |

|---|---|

| Report Name | Global MI Cable Market Report |

| Base Year | 2024 |

| Segment by Type |

· Single Core MI Cables · Multicore MI Cables · Copper-based MI Cables · Others |

| Segment by Application |

· Power Cables · Control Cables · Instrumentation Cables · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Conclusion

In conclusion, the mineral industry has shown remarkable resilience and growth, driven by innovation and regulatory compliance. The global demand for MI Cable was valued at USD 2.16 Billion in 2025, growing at a CAGR of 5.13% between 2025 and 2033. Key trends include the adoption of smart technologies and the emphasis on safety standards, particularly in the U.S., China, and Germany.

Regional drivers, such as infrastructure investments in the U.S. and China’s rapid industrialization, have significantly impacted MI Cable Market expansion. Competitive dynamics among major players like Raychem HTS, Emerson, and ABB continue to shape the industry landscape. These factors, combined with a focus on high-performance solutions, position the mineral sector for sustained growth.

Comprehensive MI Cable Market reports provide invaluable insights, guiding future strategies and reinforcing the industry’s forward-looking prospects. As the demand for reliable electrical systems grows, the mineral industry remains poised for innovation and continued success.

FAQ

What are the primary applications of mineral insulated cables?

Mineral insulated cables are widely used in high-temperature environments, such as industrial heating systems, power generation plants, and construction projects. They are also applied in fire-resistant installations due to their superior heat resistance and durability.

What materials are commonly used in the production of MI cables?

The core of MI cables is typically made from copper or stainless steel, while the insulation is composed of mineral oxides. This combination ensures excellent thermal performance and resistance to harsh conditions.

How does the global MI cable market segment by industry?

The market is segmented by industry into energy, manufacturing, and construction. Each sector has specific demands, with the energy sector driving much of the innovation in high-temperature applications.

What factors are driving the growth of the MI cable market?

Key growth drivers include increasing infrastructure investments, advancements in manufacturing technology, and rising demand for fire-resistant solutions in industrial and commercial settings.

Which regions are leading in the MI cable market?

The United States, China, and Germany are currently the leading regions. These areas are characterized by robust industrial infrastructure and stringent safety regulations, which fuel market expansion.

What are the expected market forecasts for MI cables?

Market forecasts indicate steady growth, driven by technological advancements and increasing demand for reliable high-temperature solutions. The market size is expected to expand significantly over the next five years.

How do MI cables contribute to electrical safety?

MI cables enhance electrical safety through their fire resistance and ability to maintain integrity under extreme temperatures. This makes them critical components in industrial and high-risk environments.

What role do key players play in the MI cable market?

Key players in the MI cable market are investing heavily in research and development to improve product performance and meet evolving industry standards. They also play a crucial role in setting market trends.

What are the challenges facing the MI cable market?

Challenges include high production costs, the need for specialized manufacturing techniques, and fluctuating raw material prices. These factors can impact market accessibility and growth.

How are MI cables used in the energy sector?

In the energy sector, MI cables are used for high-temperature power transmission and in environments where fire hazard is a significant concern. Their durability and reliability make them ideal for such applications.

Global MI Cable Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: MI Cable Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- MI Cable MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global MI Cable players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: MI Cable Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: MI Cable Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: MI Cable Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of MI Cable Market Insights

- Actionable Recommendations for Stakeholders