2025 Molded Pulp Packaging Market Boom: Unlocking a $5.1 Billion Opportunity with Sustainable Solutions in USA, China, and Germany

Explore the latest trends and forecasts in sustainable packaging with insights into how the US, China, and Germany are shaping the molded pulp packaging market through 2025. Analysis includes market growth predictions, regional impacts, and key factors driving industry expansion in these leading markets.

- Last Updated:

Molded Pulp Packaging Market: Q1 and Q2 2025 Predictions

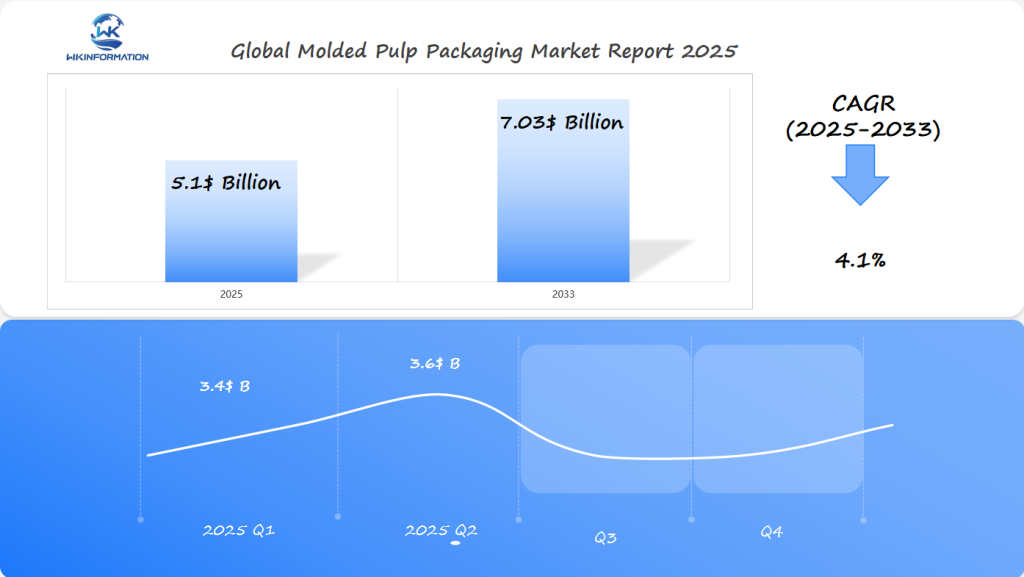

The Molded Pulp Packaging market, valued at approximately USD 5.1 billion in 2025, is projected to grow at a CAGR of 4.1% from 2025 to 2033, driven by the growing demand for sustainable packaging solutions.

In Q1 2025, the market is projected to generate around USD 1.2 billion, accounting for roughly 23% of the annual market size. This initial growth is expected to stem from rising environmental awareness in the U.S., China, and Germany, where industries are increasingly adopting eco-friendly alternatives. By Q2 2025, the market is expected to rise to around USD 1.3 billion, supported by greater regulatory pressure for sustainable packaging and consumer demand for greener products.

Understanding the Upstream and Downstream Dynamics of Molded Pulp Packaging

The molded pulp packaging industry is part of a complex supply chain that includes both upstream suppliers and downstream users.

Upstream Suppliers: The Backbone of Molded Pulp Production

At the core of this supply chain are the upstream suppliers, who provide essential raw materials such as fibrous sources. These materials, primarily derived from wood pulp as well as rapidly growing non-wood alternatives like bagasse and bamboo, ensure a steady supply of high-quality inputs for molded pulp production. The role of these suppliers is crucial, as they not only maintain the flow of materials but also influence the sustainability credentials of the final products.

Downstream Users: Industries Embracing Eco-Friendly Packaging

On the other end, downstream users encompass a wide range of industries utilizing molded pulp for its eco-friendly properties. Key sectors include:

- Food Service: Demand for trays, containers, and clamshells to handle hot and greasy foods.

- Electronics: Focus on protective packaging that offers durability during transit while being lightweight.

- Consumer Goods: Requirement for versatile and aesthetically pleasing designs catering to diverse product lines.

These industries prioritize specific attributes such as recyclability, biodegradability, and cost-effectiveness from their packaging solutions.

Innovation Through Collaboration

The interaction between suppliers and manufacturers provides fertile ground for innovation. Collaboration opportunities abound in areas like developing new molding processes or enhancing material compositions to meet stringent sustainability targets. Such partnerships are vital in driving technological advancements that can transform production processes, reducing costs while boosting efficiency.

Strategic Alliances for Sustainable Growth

This intricate interplay within the supply chain underscores the need for strategic alliances aimed at fostering growth through sustainable practices. As market demands evolve, adaptability within these dynamics will be pivotal in maintaining competitive advantage across the industry landscape.

Key Trends and Innovations Shaping the Future of Molded Pulp Packaging

The molded pulp packaging industry is undergoing a significant transformation, driven by several key trends and innovations that are shaping its future. Here are some of the most important factors influencing the industry:

1. Shift Towards Biodegradable Materials

The molded pulp packaging industry is witnessing a significant shift towards biodegradable materials, catering to the growing consumer demand for sustainable solutions. This trend is largely driven by an increasing preference for compostable materials that mitigate environmental impact. As consumers become more environmentally conscious, companies are investing in biodegradable options to meet these expectations and contribute to reducing their carbon footprint.

2. Technological Advancements in Production

Technological advancements play a crucial role in the evolution of molded pulp packaging. Innovations in production techniques, such as advanced molding processes and automated systems, have enhanced both efficiency and design versatility. These technologies allow manufacturers to produce intricate designs with improved precision, meeting diverse customer needs across various sectors. The integration of automation not only boosts productivity but also minimizes waste, aligning with eco-friendly trends.

3. Embracing Circular Economy Practices

Another notable development is the industry’s movement towards circular economy practices. Emphasizing recyclability and reusability, companies are rethinking product life cycles to foster sustainability. Molded pulp products are increasingly designed for multiple uses, promoting longer life spans and reducing the need for single-use alternatives. This approach not only conserves resources but also supports regulatory compliance as governments worldwide implement stricter environmental regulations.

To illustrate, companies like Huhtamaki Oyj are at the forefront of adopting these practices, showcasing how innovation can drive change within the packaging landscape. By focusing on sustainable solutions, they set a benchmark for others in the industry.

These key trends underscore a transformative phase for molded pulp packaging, where innovation meets ecological responsibility. As technology continues to evolve alongside consumer preferences and regulatory frameworks, expecting ongoing developments that further enhance sustainability is reasonable.

Overcoming Challenges in Scaling Up Molded Pulp Packaging Production

The Molded Pulp Packaging Market is not without its hurdles, especially when scaling up production. One of the most pressing issues is the tightening of recycling regulations. These policies are crucial for ensuring environmental sustainability but can also impose significant constraints on manufacturers. Compliance with these regulations often requires substantial investment in new technologies and processes, which can be a barrier to entry for smaller companies.

Fluctuating raw material prices present another challenge. The cost of key inputs such as recycled paper and cardboard can vary significantly due to market dynamics, affecting production costs and squeezing profit margins. This volatility necessitates strategic sourcing and inventory management to mitigate financial risks.

Addressing these challenges requires innovative strategies:

- Investment in Technology: Upgrading to more efficient production systems can help streamline operations and reduce waste, aligning with recycling standards while lowering costs.

- Sustainable Sourcing: Developing partnerships with stable suppliers of raw materials ensures a consistent supply chain, reducing exposure to price fluctuations.

- Regulatory Compliance Expertise: Engaging specialists in environmental law can aid in navigating complex regulations, ensuring compliance, and avoiding costly penalties.

By employing these strategies, manufacturers can better position themselves to capitalize on the growing demand for eco-friendly packaging solutions. The ability to adapt and innovate will be key in overcoming production challenges and achieving sustainable growth within the molded pulp packaging industry.

Geopolitical Factors Influencing the Global Landscape of Molded Pulp Packaging Industry

Navigating the global landscape of the molded pulp packaging industry requires a keen understanding of trade policies and their impact on competitiveness. Tariff barriers, such as import duties, can significantly affect pricing strategies, making it challenging for manufacturers to compete in foreign markets. Non-tariff measures, including quotas and import restrictions, further complicate market access. These elements play a crucial role in shaping the regional distribution of molded pulp products.

Environmental regulations across different countries are pivotal in defining market dynamics. Nations with stringent environmental policies often drive innovation within the industry, pushing manufacturers to develop more sustainable solutions. For instance, Europe’s strong emphasis on reducing carbon emissions has accelerated advancements in biodegradable packaging options. In contrast, regions with lenient regulations may lag in adopting eco-friendly alternatives.

Geopolitical tensions introduce another layer of complexity to supply chains for molded pulp manufacturers. Political instability or diplomatic conflicts can disrupt trade routes and increase transportation costs. Companies must remain agile, adapting sourcing strategies to mitigate risks associated with volatile geopolitical climates.

Understanding these factors is essential for stakeholders aiming to capitalize on the burgeoning opportunities within the molded pulp packaging arena. As markets become increasingly interconnected, being aware of how trade policies and environmental regulations influence global market dynamics will empower businesses to make informed decisions and thrive amidst changing geopolitical landscapes.

By aligning with international standards and fostering innovation, companies can navigate these challenges effectively while contributing to a more sustainable future in packaging solutions.

Types of Molded Pulp Packaging Solutions and Their Benefits

Molded pulp packaging is an eco-friendly alternative to traditional plastic and foam packaging, made from recycled paper, cardboard, or other natural fibers. It is widely used in various industries due to its sustainability, cost-effectiveness, and protective qualities. There are four main types of molded pulp packaging solutions:

-

Thick-Walled Molded Pulp – This type is rigid and durable, typically used for heavy-duty packaging applications like automotive and industrial parts. It provides excellent shock absorption and structural integrity.

-

Transfer Molded Pulp – Commonly found in egg cartons, drink carriers, and electronic packaging, this type has a smooth surface on one side and a textured finish on the other. It is lightweight, cost-efficient, and ideal for retail packaging.

-

Thermoformed Molded Pulp – Also known as precision molded pulp, this solution is created using heat and pressure, resulting in a smooth, high-quality finish. It is often used for premium product packaging, including cosmetics, electronics, and luxury goods.

-

Processed Molded Pulp – This type undergoes additional treatments such as coatings, laminations, or coloring to enhance its moisture resistance, durability, and aesthetic appeal. It is widely used in food packaging, medical trays, and custom-designed applications.

Benefits of Molded Pulp Packaging

- Eco-Friendly: Made from recycled materials and biodegradable, it reduces environmental impact.

- Cost-Effective: Lower material and production costs compared to plastic and foam alternatives.

- Protective: Offers cushioning and shock absorption for fragile items.

- Customizable: Can be molded into various shapes and sizes for specific product needs.

- Lightweight: Reduces transportation costs and enhances handling efficiency.

As businesses and consumers increasingly prioritize sustainability, molded pulp packaging solutions provide a viable, eco-conscious alternative that meets both environmental and functional demands.

Exploring Diverse Applications: Molded Pulp Packaging Solutions Across Industries

The versatility of molded pulp packaging shines across a range of industries, offering sustainable solutions while meeting specific functional needs. One major area where this type of packaging excels is the food service industry.

1. Food Service Trays and Containers

Molded pulp is ideally suited for creating trays and containers used in food service. These products accommodate hot and greasy foods effectively, making them a popular choice among quick-service restaurants and catering services. The natural insulating properties of molded pulp help maintain food temperature, enhancing consumer satisfaction. Additionally, its compostable nature aligns with the growing consumer demand for eco-friendly options.

In the realm of electronics, molded pulp packaging provides another set of benefits:

2. Electronics Packaging

The electronics sector leverages molded pulp’s ability to offer superior protection during transit. This packaging type is not only lightweight but also cost-effective, making it an attractive option for companies looking to reduce shipping costs without compromising on product safety. Molded pulp can be customized to fit various shapes and sizes, ensuring that delicate electronic components are cushioned against shocks and vibrations.

These applications demonstrate how molded pulp packaging meets diverse industry needs while emphasizing sustainability. By providing robust protection and maintaining environmental responsibility, molded pulp continues to gain traction across sectors seeking innovative and green packaging solutions.

Regional Insights: Growth Drivers Behind Asia Pacific Dominance in Molded Pulp Packaging Market

The Asia Pacific region stands out as a powerhouse in the molded pulp packaging market, driven by several key factors. Rising disposable income levels across countries like China and India have significantly amplified the demand for packaged goods. This economic growth facilitates increased consumer spending, particularly on food and beverage products that heavily rely on sustainable packaging solutions.

Key Factors Contributing to Market Expansion:

- Rising Disposable Income: As consumers’ purchasing power increases, there is a heightened preference for quality and convenience in packaging, pushing demand for molded pulp products.

- Booming Food and Beverage Industry: The region’s extensive food service sector continues to expand, with a growing emphasis on eco-friendly and recyclable packaging materials.

- Government Initiatives: Proactive regulations promoting environmentally sustainable practices support the adoption of biodegradable packaging solutions.

These elements collectively position Asia Pacific as a dominant player in the global molded pulp packaging market, setting a benchmark for other regions to emulate. This expansion not only signifies regional growth but also highlights the potential for further innovation and investment within this sector.

The USA’s Role as an Innovation Leader in Sustainable Packaging Technologies

The United States is a major player in the molded pulp packaging market, leading the way with innovative solutions focused on sustainability. Leading companies like Huhtamaki are at the forefront, revolutionizing traditional packaging methods with environmentally friendly practices and advanced technologies. Their dedication to innovation reflects broader trends in the USA market, highlighting sustainable solutions designed for various industries.

Key Initiatives by Leading Companies

Huhtamaki, along with industry counterparts such as Sonoco Products Co. and Genpak LLC, leads efforts that prioritize materials which can decompose naturally or be recycled. By concentrating on minimizing carbon footprints, these companies are in sync with the increasing consumer demand for environmental responsibility.

Technological Advancements in Production

The USA market shows a strong emphasis on technological progress, integrating automated systems and sophisticated molding processes to improve production efficiency and design capabilities.

Collaboration for Compliance and Innovation

Partnerships between manufacturers and environmental agencies are another aspect of the USA’s leadership in this field, ensuring adherence to strict regulations while promoting innovation.

This vibrant environment not only establishes the USA as a leader in sustainable packaging but also sets a standard for other regions aiming to achieve eco-friendly objectives. As businesses continue to evolve, the molded pulp sector holds great promise for exciting advancements in sustainability and innovation.

China’s Growing Demand for Molded Pulp Packaging Amidst Environmental Concerns

China’s rapidly growing economy is a major factor driving the increasing demand for molded pulp packaging. As disposable incomes rise and the consumer market expands, there is a greater need for packaging solutions that cater to various industries such as food service, electronics, and consumer goods.

1. Economic Growth and Consumer Behavior

As China’s economy continues to grow, so does its middle class. This shift in demographics is leading to more packaged goods being consumed, which in turn creates a greater need for sustainable packaging solutions like molded pulp products.

2. Environmental Challenges

Addressing environmental issues has become critically important in China. The government is implementing stricter regulations to reduce plastic waste and promote eco-friendly alternatives. Molded pulp packaging, made from renewable resources like recycled paper and cardboard, aligns with these regulatory goals and public expectations for sustainability.

3. Sustainable Innovation

Chinese manufacturers are adopting advanced production techniques to effectively meet these demands. They are investing in technology that improves the recyclability and biodegradability of molded pulp products, positioning the industry as a leader in sustainable practices.

With these factors at play, the Chinese market is expected to play a crucial role in the global molded pulp packaging industry, balancing economic growth with environmental responsibilities.

Germany’s Contribution to the Molded Pulp Packaging Market in Latin America

Germany plays a crucial role in the molded pulp packaging market, extending its influence beyond Europe into regions like Latin America. German manufacturers are known for their innovative approaches to sustainable packaging, which have become benchmarks for other markets. Their expertise in engineering efficient production processes and integrating environmentally friendly technologies gives Latin American businesses a competitive edge.

Key Contributions:

- Technological Transfer: German companies often partner with Latin American firms to transfer cutting-edge technology, enhancing local manufacturing capabilities. This collaboration helps Latin American companies improve product quality and production efficiency.

- Sustainability Practices: Germany’s commitment to sustainability has inspired similar practices in Latin America. By adopting eco-friendly production methods and using renewable resources, German firms encourage local manufacturers to align with global environmental standards.

- Market Expansion Strategies: German businesses frequently engage in joint ventures and strategic alliances with Latin American partners. These collaborations facilitate market penetration, offering German expertise while leveraging local market knowledge.

Example: Companies such as Pöppelmann GmbH & Co. KG are leading the way in these efforts, providing sustainable solutions that resonate with eco-conscious consumers in Latin America.

As Germany continues to drive sustainable innovation, its impact on the molded pulp packaging market across different continents remains significant, setting a high standard for global industry practices.

Future Innovations on Horizon: Anticipating Next-Generation Developments in Molded Pulp Manufacturing Processes

The Molded Pulp Packaging Market is on the brink of several exciting transformations, with emerging technologies set to redefine its landscape. As companies push for greater efficiency and functionality, a few key innovations are poised to lead the way:

1. Advanced Molding Techniques

The integration of cutting-edge molding processes promises enhanced precision and reduced waste. New techniques aim to streamline production while maintaining structural integrity and design flexibility.

2. Smart Packaging Solutions

Incorporating technology into molded pulp products could revolutionize usability. Imagine packaging that not only protects but also interacts with consumers via embedded sensors or QR codes.

3. Eco-Friendly Material Innovations

The development of new bio-based materials will further reduce environmental impact. These materials, potentially derived from agricultural by-products, could offer the same durability as traditional options with an even smaller carbon footprint.

Such advancements highlight a commitment to sustainability without compromising performance. Industry leaders are investing heavily in research and development, seeking breakthroughs that align with consumer demands for greener solutions. As these technologies mature, they are expected to drive significant shifts within the sector, opening new avenues for growth and innovation.

Leading Competitors Driving Growth Within The Global Molded Pulp Packaging Market

In the competitive landscape of the Molded Pulp Packaging Market, several major players are leading the way in innovation and expansion.

- Huhtamaki Oyj

- Brodrene Hartmann A/S

- UFP Technologies

- Sabert Corporation

- Sonoco Products Co.

- Genpak LLC

- Fabri-Kal

- Pro-Pac Packaging

- Enviropak Corporation

- Smurfit Kappa

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Molded Pulp Packaging Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The molded pulp packaging market is at the forefront of innovation and sustainability, with the potential for significant growth by 2025. As consumers increasingly seek eco-friendly options, molded pulp products provide an attractive alternative to conventional packaging. Key regions such as the USA, China, and Germany are leading this movement, driven by government regulations and economic development.

Factors Driving Growth

Several factors are contributing to the promising future of molded pulp packaging:

- Technological advancements: Improvements in production processes are making manufacturing more efficient and allowing for greater design flexibility. This enables producers to cater to various industries’ requirements.

- Environmental considerations: The demand for biodegradable and recyclable packaging solutions is on the rise. Businesses can align themselves with global sustainability objectives by adopting molded pulp materials.

- Challenges as opportunities: While there are obstacles such as fluctuating raw material prices and strict recycling laws, these challenges also present opportunities for innovation in sourcing and production techniques.

The Importance of Collaboration

The dynamics of international trade and competition are influenced by geopolitical factors. Therefore, it is essential for all parties involved—suppliers, manufacturers, distributors—to work together in order to navigate these complexities effectively.

By embracing these trends and overcoming challenges through collaboration, the molded pulp packaging industry has the potential for significant growth. Prioritizing sustainable practices not only benefits the environment but also promotes long-term economic development worldwide.

Global Molded Pulp Packaging Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Molded Pulp Packaging Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Molded Pulp Packaging Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global Molded Pulp Packaging Players and Regional Insights

-

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

-

- Key Differentiators and Strategic Moves

Chapter 3: Molded Pulp Packaging Market Segmentation Analysis

- Key Data and Visual Insights

-

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

-

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

-

- Historical Data and Growth Forecasts

- Regional Growth Factors

-

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Molded Pulp Packaging Emerging and Untapped Markets

- Growth Potential in Secondary Regions

-

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Molded Pulp Packaging Consumer Insights

- Demographics and Buying Behaviors

-

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Molded Pulp Packaging Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the molded pulp packaging market and why is it significant?

The molded pulp packaging market refers to the production and use of eco-friendly packaging solutions made from recycled paper and other natural fibers. Its significance lies in its contribution to sustainable packaging efforts, addressing environmental concerns by providing biodegradable alternatives to traditional plastic packaging.

What are the projected growth trends for the molded pulp packaging market by 2025?

Market projections indicate that the molded pulp packaging sector is expected to experience substantial growth by 2025, particularly in key regions like the USA, China, and Germany. This growth is driven by increasing demand for eco-friendly packaging solutions and supportive regulatory frameworks.

What challenges does the molded pulp packaging industry face in scaling up production?

The industry faces several challenges including stringent recycling regulations, fluctuations in raw material prices, and production difficulties during large-scale manufacturing. Addressing these challenges is crucial for enhancing profitability and ensuring widespread adoption of molded pulp products.

How are geopolitical factors influencing the molded pulp packaging industry globally?

Geopolitical factors such as international trade policies and environmental regulations significantly impact the competitiveness of molded pulp products. Tariff barriers and non-tariff measures can affect market dynamics, while geopolitical tensions may disrupt supply chains for manufacturers operating on a global scale.

What innovations are shaping the future of molded pulp packaging?

Key innovations include advancements in biodegradable materials, improved production techniques utilizing automation, and a shift towards circular economy practices that emphasize recyclability and reusability. These trends enhance efficiency and meet consumer demands for sustainable options.

Which industries are major users of molded pulp packaging solutions?

Molded pulp packaging is widely utilized across various industries including food service, where it excels in applications like trays and containers for hot or greasy foods, as well as in the electronics sector, where it provides lightweight protection during transit.