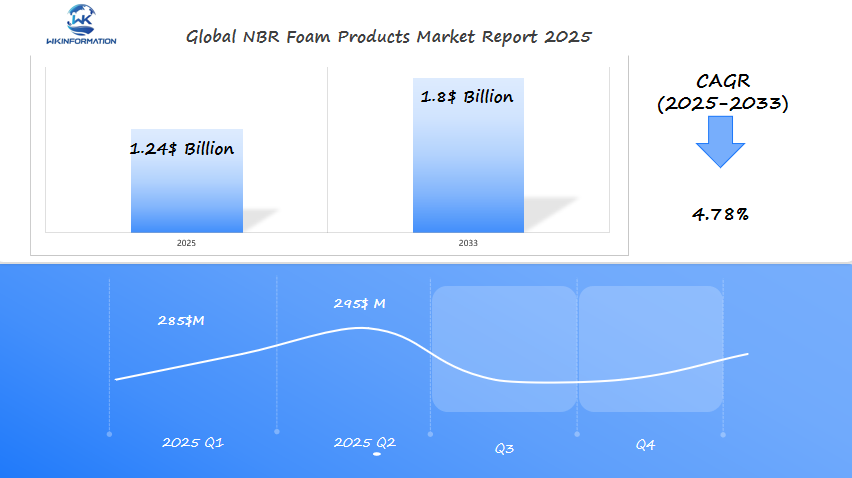

NBR Foam Products Market Poised to Surpass $1.24 Billion by 2025 Backed by Thermal Insulation Demand in the U.S., Germany, and Japan

The NBR (Nitrile Butadiene Rubber) foam products market forecast for Q1-Q2 2025 highlights key trends, growth projections, and influential factors shaping the industry. This analysis explores the market dynamics, including technological advancements, regional growth, and competitive shifts that will define the NBR foam products landscape in the coming months.

- Last Updated:

NBR Foam Products Market Outlook for Q1 and Q2 2025

The NBR Foam Products market is projected to reach $1.24 billion in 2025, with a CAGR of 4.78% from 2025 to 2033. In Q1 2025, the market is expected to be valued at approximately $285 million, driven by applications in automotive, construction, and industrial sectors, particularly in the U.S., Germany, and Japan. NBR (Nitrile Butadiene Rubber) foam’s excellent resistance to oils, fuels, and chemicals makes it highly sought after in these industries, particularly in the automotive sector where it is used for seals, gaskets, and insulation.

By Q2 2025, the market is forecast to grow to $295 million, as the demand for high-performance materials in industrial applications continues to rise. The U.S. will remain a key market due to the robust automotive and industrial sectors, while Germany’s emphasis on automotive innovation and Japan’s advanced manufacturing capabilities in electronics and automotive industries will further fuel growth. The market will continue to benefit from innovations in material science and the push towards more durable and sustainable solutions.

Key Takeaways

- Growing demand for thermal insulation drives market growth.

- The U.S. and Germany are key contributors to market expansion.

- Market is projected to surpass $1.24 billion by 2025.

- Increasing industrial applications fuel demand forNBR foam products.

- Technological advancements enhance product efficiency.

Understanding the NBR Foam Products Market Supply Chain

Understanding the supply chain dynamics of NBR Foam Products is crucial for manufacturers and stakeholders to navigate the market effectively. The NBR Foam Products market involves various players, including raw material suppliers, manufacturers, distributors, and end-users.

Upstream Suppliers: The Key to Quality Raw Materials

The supply chain starts with the production of raw materials, such as nitrile rubber, which is the main ingredient in NBR Foam Products. Upstream suppliers are essential in providing top-notch raw materials that meet the specific requirements for making NBR Foam Products.

NBR Foam Products Market Supply Chain

The manufacturing process involves the compounding and foaming of nitrile rubber, which is then processed into various forms such as sheets, rolls, or custom shapes. Efficient manufacturing processes are essential to ensure the quality and consistency of the final products.

Downstream Segment

The downstream segment of the supply chain involves the distribution and sale of NBR Foam Products to various end-use industries, including automotive, construction, and HVAC. Understanding the needs and preferences of these end-users is vital for manufacturers to tailor their products and services accordingly.

Effective Management

Effective management of the supply chain is crucial for the success of NBR Foam Products manufacturers. It involves coordinating with suppliers, optimizing manufacturing processes, and ensuring timely delivery to customers.

Growing Need for Better Insulation in HVAC and Automotive Systems

Thermal efficiency and sound insulation are now crucial in designing and running modern HVAC (Heating, Ventilation, and Air Conditioning) and automotive systems. As industries work to use less energy and meet stricter regulations, the need for effective insulation materials has increased significantly.

NBR Foam Products have become a popular option because they offer excellent thermal efficiency (ability to retain heat) and sound insulation (blocking noise) qualities.

Thermal Efficiency, Sound Insulation

The need for thermal efficiency is crucial in industries where energy conservation is important. NBR Foam Products offer superior thermal insulation, reducing heat transfer and energy loss. In HVAC systems, these products help maintain consistent temperatures, improving system efficiency and reducing operational costs.

Similarly, in automotive applications, NBR Foam Products contribute to better engine performance and reduced noise pollution.

HVAC, Automotive Applications

In HVAC systems, NBR Foam Products are used for insulation, helping to minimize energy loss and reduce the strain on heating and cooling systems. Their application in automotive industries is diverse, ranging from engine mounts to soundproofing materials.

The versatility of NBR Foam Products makes them an essential component in the manufacture of vehicles and HVAC equipment.

The benefits of using NBR Foam Products in these applications are multifaceted. They not only enhance thermal efficiency and reduce noise but also contribute to the overall durability and performance of the systems.

As the demand for energy-efficient and environmentally friendly solutions continues to grow, the role of NBR Foam Products is expected to become even more significant.

Regulatory constraints and raw material availability challenges

The growth of the NBR Foam Products Market is influenced by regulatory constraints and raw material availability. Regulatory constraints, in particular, play a crucial role in shaping the market’s dynamics. Stringent regulations regarding the production, usage, and disposal of NBR foam products can significantly impact the market’s growth.

Raw material availability is another critical factor affecting the NBR Foam Products Market. The availability of raw materials, such as nitrile rubber, can be impacted by various factors, including geopolitical tensions, trade policies, and supply chain disruptions. Ensuring a stable supply of raw materials is essential for manufacturers to maintain production levels and meet growing demand.

Regulatory Constraints

Regulatory constraints can take many forms, such as environmental regulations, safety standards, and trade policies. For example, regulations aimed at reducing environmental impact can lead to increased production costs for manufacturers. Manufacturers must comply with these regulations to avoid potential penalties and maintain their market presence.

Raw Material Availability

The availability of raw materials is critical for the production of NBR foam products. Fluctuations in raw material prices can significantly impact production costs and profitability. To manage raw material availability risks, manufacturers can adopt strategies such as diversifying their supplier base, investing in supply chain management, and developing alternative materials.

By understanding the challenges posed by regulatory constraints and raw material availability, stakeholders can navigate the NBR Foam Products Market more effectively. Developing strategies to mitigate these challenges can help manufacturers maintain their competitiveness and capitalize on emerging opportunities.

Geopolitical factors impacting supply of synthetic rubber

Geopolitical tensions are significantly impacting the production and distribution of synthetic rubber, a critical component in the manufacture of NBR Foam Products. The NBR Foam Products Market is closely tied to the availability and pricing of synthetic rubber, which is influenced by geopolitical factors.

The global supply chain for synthetic rubber is complex, involving multiple countries and manufacturers. Geopolitical instability in key producing regions can lead to supply chain disruptions, affecting the availability and cost of synthetic rubber. As noted by industry experts, “The ongoing geopolitical tensions have resulted in significant fluctuations in the global supply of synthetic rubber, impacting the NBR Foam Products Market.”

Geopolitical Factors Affecting Synthetic Rubber

Several geopolitical factors are currently influencing the supply of synthetic rubber. These include trade tensions between major economies, sanctions on key producers, and political instability in regions with significant synthetic rubber production capacities.

- Trade tensions can lead to tariffs and other trade barriers, increasing the cost of synthetic rubber.

- Sanctions on major synthetic rubber-producing countries can restrict supply, leading to shortages and price volatility.

- Political instability in key production regions can disrupt production and distribution networks.

These factors contribute to an uncertain environment for the NBR Foam Products Market, as manufacturers face challenges in securing a stable supply of synthetic rubber at predictable prices.

“The impact of geopolitical factors on the supply of synthetic rubber cannot be overstated. It is crucial for stakeholders in the NBR Foam Products Market to closely monitor geopolitical developments and adjust their strategies accordingly.”

The Synthetic Rubber market is expected to continue facing challenges due to geopolitical factors. Companies involved in the production of NBR Foam Products must develop strategies to mitigate these risks, such as diversifying their supply chains and investing in alternative materials.

Market segmentation by density, thickness, and form

Market segmentation is a critical aspect of the NBR Foam Products Market, influencing product development and marketing strategies. By understanding the different segments based on density, thickness, and form, manufacturers can tailor their products to meet specific customer needs.

Density

The density of NBR foam products is a crucial factor in determining their application and performance. Low-density foams are often used in applications where flexibility and lightweight properties are essential, such as in certain automotive and industrial applications. On the other hand, high-density foams are preferred in situations requiring greater durability and resistance to compression, such as in construction and heavy industrial settings.

Thickness

The thickness of NBR foam products is another significant segmentation criterion. Thin foams are typically used for applications requiring precision and minimal material usage, such as in gaskets and seals. In contrast, thicker foams are utilized in applications where insulation and cushioning are critical, such as in HVAC systems and soundproofing.

Form

NBR foam products come in various forms, including sheets, rolls, and custom molded shapes. The choice of form depends on the specific application and the manufacturing process. For instance, sheets and rolls are commonly used in large-scale industrial applications, while custom molded shapes are preferred in specialized applications requiring precise dimensions and shapes.

Understanding these segmentation strategies enables manufacturers to develop targeted marketing campaigns and product development initiatives, ultimately enhancing their competitiveness in the NBR Foam Products Market.

Application in HVAC, automotive, construction, and industrial insulation

With its unique properties, NBR Foam is being increasingly used in various sectors such as HVAC, automotive, construction, and industrial insulation. The versatility of NBR Foam Products makes them an ideal material for industries requiring thermal and sound insulation.

NBR Foam Products Applications

NBR Foam Products are widely used in the HVAC industry for their excellent thermal insulation properties. They help in reducing energy consumption by maintaining the desired temperature within buildings. The use of NBR Foam in HVAC systems also contributes to noise reduction, enhancing overall system efficiency.

In addition to HVAC applications, NBR Foam is also making significant strides in the automotive sector, where it’s used for soundproofing and thermal insulation. This not only enhances comfort but also improves energy efficiency in vehicles.

In the construction industry, NBR Foam’s thermal insulation properties are leveraged to create energy-efficient buildings. Its lightweight nature also makes it easier to handle and install.

Lastly, in the realm of industrial insulation, NBR Foam’s durability and resistance to harsh conditions make it a preferred choice for insulating pipes and equipment.

Key Industries Benefiting from NBR Foam

The automotive sector is another significant consumer of NBR Foam Products. These products are used in vehicle manufacturing for soundproofing and thermal insulation, improving the overall driving experience. NBR Foam’s resistance to oils and temperature variations makes it particularly suitable for automotive applications.

In the construction industry, NBR Foam is utilized for its insulation properties, helping to reduce energy costs and enhance building efficiency. It is used in various construction elements, including walls, floors, and ceilings, to provide thermal and acoustic insulation.

NBR Foam Products Applications

- Industrial insulation is another critical area where NBR Foam Products play a vital role. They are used to insulate equipment and pipelines, reducing heat loss and preventing damage from extreme temperatures. The durability of NBR Foam makes it a preferred choice for industrial applications.

- The benefits of NBR Foam Products across these industries include improved energy efficiency, reduced noise pollution, and enhanced product durability. As these industries continue to evolve, the demand for NBR Foam is expected to grow, driven by its versatile applications and performance.

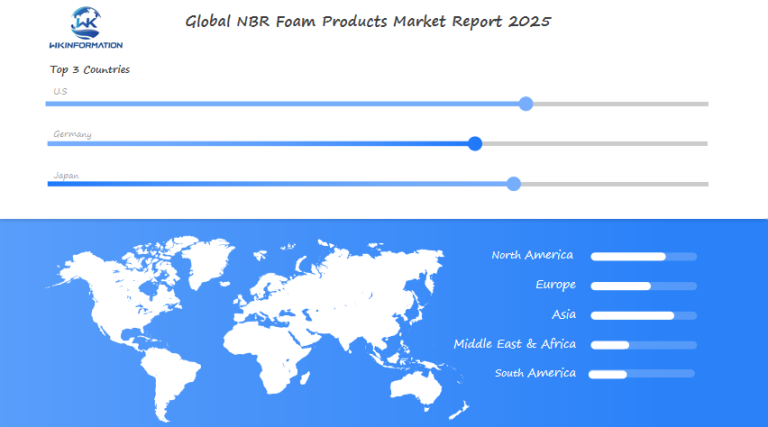

Regional adoption trends shaping the global NBR Foam Products market

As the global NBR Foam Products market continues to evolve, regional adoption trends are emerging as a key factor influencing its growth. The diverse regional adoption trends are driven by varying factors, including economic conditions, regulatory environments, and industry demands.

North America: Leading the Way in NBR Foam Products Adoption

The North American region, particularly the United States, is witnessing a significant adoption of NBR Foam Products due to its growing construction and automotive industries. The increasing demand for energy-efficient buildings and lightweight automotive components is driving the growth of the NBR Foam Products market in this region.

Europe: Stringent Regulations Fueling NBR Foam Products Adoption

In Europe, the adoption of NBR Foam Products is driven by the region’s stringent regulations on energy efficiency and environmental sustainability. Germany, in particular, is a significant market for NBR Foam Products due to its strong automotive industry and focus on reducing carbon emissions.

Regional Adoption Trends

The Asia-Pacific region is also experiencing rapid growth in the NBR Foam Products market, driven by the increasing demand from the construction, automotive, and industrial sectors. Countries such as China, Japan, and South Korea are witnessing significant adoption of NBR Foam Products due to their expanding manufacturing capabilities and growing infrastructure projects.

The regional adoption trends are not only driven by local factors but also influenced by global market dynamics. The global NBR Foam Products market is becoming increasingly interconnected, with regional players competing and collaborating to meet the growing demand for NBR Foam Products.

Key regional adoption trends shaping the global NBR Foam Products market include:

- Increasing demand from the construction and automotive industries

- Growing focus on energy efficiency and environmental sustainability

- Rapid industrialization and infrastructure development in emerging economies

- Technological advancements and innovations in NBR Foam Products

Understanding these regional adoption trends is crucial for stakeholders to identify opportunities and challenges in the global NBR Foam Products market. By analyzing regional dynamics, businesses can develop targeted strategies to capitalize on emerging trends and stay competitive in the market.

U.S. infrastructure and building efficiency driving foam usage

U.S. infrastructure development is significantly boosting the demand for NBR Foam Products due to its role in enhancing building efficiency. As the country’s infrastructure continues to evolve, the need for high-performance insulation materials like NBR Foam Products is becoming increasingly important.

The U.S. government has been investing heavily in infrastructure projects, which has led to a surge in the demand for NBR Foam Products. These products are used in various applications, including HVAC systems, automotive, and construction, due to their excellent thermal insulation properties and ability to reduce energy consumption.

U.S. Infrastructure

The development of U.S. infrastructure is a critical factor driving the demand for NBR Foam Products. As new infrastructure projects are undertaken, the need for efficient and effective insulation solutions becomes more pressing. NBR Foam Products are well-suited to meet this demand, providing excellent thermal insulation and contributing to the overall energy efficiency of buildings.

The use of NBR Foam Products in infrastructure projects also has a positive impact on the environment. By reducing energy consumption and minimizing heat loss, these products help to lower greenhouse gas emissions and mitigate the environmental impact of buildings.

Building Efficiency

Building efficiency is another key driver of the demand for NBR Foam Products in the U.S. As the country continues to focus on reducing energy consumption and promoting sustainable building practices, the demand for high-performance insulation materials like NBR Foam Products is expected to grow.

NBR Foam Products play a crucial role in enhancing building efficiency by providing excellent thermal insulation, reducing heat loss, and minimizing energy consumption. The use of these products in building construction can lead to significant energy savings and a reduced environmental impact.

| Application | Benefits |

| HVAC Systems | Excellent thermal insulation, reduced energy consumption |

| Construction | Improved building efficiency, reduced heat loss |

| Automotive | Lightweight, improved fuel efficiency |

The growing demand for NBR Foam Products in the U.S. is driven by the need for efficient and effective insulation solutions. As the country’s infrastructure continues to evolve and the focus on building efficiency grows, the demand for these products is expected to remain strong.

Germany’s automotive sector favoring lightweight insulation

Germany’s automotive manufacturers are turning to NBR Foam Products to meet the need for lightweight and efficient insulation solutions. The automotive industry is a significant consumer of these products, driven by the demand for thermal efficiency and sound insulation.

Lightweight Insulation Benefits

NBR Foam Products offer several benefits, including reduced weight, improved thermal insulation, and enhanced sound dampening. These advantages are crucial in the automotive sector, where minimizing weight is key to improving fuel efficiency and reducing emissions.

The use of NBR Foam Products in vehicles also contributes to a more comfortable driving experience by reducing noise levels. Moreover, these products are versatile and can be used in various applications, from HVAC systems to engine compartments.

NBR Foam Products in Automotive Industry

NBR Foam Products are utilized in several critical areas of vehicle manufacturing, including:

- Thermal insulation in engine compartments

- Sound insulation in vehicle interiors

- Sealing and gasketing applications

The following table highlights the advantages of NBR Foam Products in the automotive sector:

| Application | Benefits |

| Thermal Insulation | Reduces heat transfer, improving engine efficiency |

| Sound Insulation | Minimizes noise levels, enhancing driver comfort |

| Sealing and Gasketing | Provides durable seals, reducing vibrations and noise |

By adopting NBR Foam Products, Germany’s automotive manufacturers can achieve significant improvements in vehicle performance, efficiency, and comfort. As the industry continues to evolve, the demand for these innovative materials is expected to grow.

Japan’s energy efficiency policies accelerating adoption

Japan’s commitment to energy efficiency is significantly boosting the demand for NBR Foam Products. The country’s rigorous energy policies are designed to reduce energy consumption and greenhouse gas emissions, driving industries to adopt more energy-efficient solutions.

NBR Foam Products Adoption

The adoption of NBR Foam Products in Japan is on the rise due to their excellent thermal insulation properties and ability to meet the country’s stringent energy efficiency standards. These products are being increasingly used in various industries, including construction, automotive, and HVAC.

Key drivers of NBR Foam Products adoption in Japan include:

- Government regulations and policies promoting energy efficiency

- Growing demand for energy-efficient building materials

- Increasing use of NBR Foam Products in the automotive sector for sound insulation and thermal efficiency

The Japanese government has implemented various initiatives to promote energy efficiency, such as the Energy Conservation Law and the Top Runner Program. These initiatives have created a favorable environment for the adoption of NBR Foam Products.

As Japan continues to prioritize energy efficiency, the demand for NBR Foam Products is expected to grow. Manufacturers are responding by developing innovative products that meet the country’s energy efficiency standards.

Emerging formulations and technology in NBR Foam Products

Emerging formulations and technology in NBR Foam Products

The NBR Foam Products market is on the verge of a major change, driven by new formulations and technologies that promise better performance and sustainability. As the demand for high-quality insulation materials continues to grow, manufacturers are investing heavily in research and development to stay ahead of the competition.

Key drivers of innovation in the NBR Foam Products market

One of the main factors driving innovation in the NBR Foam Products market is the development of new formulations. Advanced compounding techniques are being used to create foams with improved thermal insulation properties, reduced toxicity, and enhanced durability. For example, the use of nanomaterials in NBR foam formulations has been shown to improve their thermal conductivity and mechanical properties.

Emerging Formulations

Some of the emerging formulations in NBR Foam Products include:

- Blends of NBR with other polymers, such as PVC or EPDM, to create foams with improved properties

- Use of alternative blowing agents, such as CO2 or hydrocarbons, to reduce environmental impact

- Incorporation of functional fillers, such as silica or talc, to enhance foam performance

These emerging formulations are expected to drive growth in the NBR Foam Products market, as manufacturers look to differentiate their products and meet evolving customer needs.

Technology in NBR Foam Products

Advances in technology are also playing a critical role in shaping the NBR Foam Products market. Improved manufacturing processes, such as continuous compounding and foam extrusion, are enabling the production of high-quality foams with consistent properties.

The use of advanced testing and characterization techniques is also becoming more prevalent, allowing manufacturers to better understand the properties of their foams and optimize their formulations accordingly.

| Emerging Formulation | Key Benefits |

| NBR-PVC blends | Improved flexibility, reduced toxicity |

| CO2 blowing agents | Reduced environmental impact, improved insulation properties |

| Functional fillers | Enhanced foam performance, improved mechanical properties |

As the NBR Foam Products market continues to evolve, it is likely that emerging formulations and technologies will play an increasingly important role in shaping the industry. By staying ahead of the curve, manufacturers can capitalize on new opportunities and drive growth in the market.

Competitive landscape among insulation product manufacturers

- W. KÖPP — Mönchengladbach, Germany

- RG Rom Gummi — Buchholz in der Nordheide, Germany

- Ridderflex — Ridderkerk, Netherlands

- Armacell — Münster, Germany

- Fostek Corporation — Suzhou, China

- Roop Koepp — Hilden, Germany

- L’isolante K-Flex — Busto Arsizio, Italy

- Kaimann GmbH — Wenden, Germany

- Huamei Energy-Saving — Ningbo, China

- Aeroflex — London, UK

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global NBR Foam Products Market Report |

| Base Year | 2024 |

| Segment by Type | · Automotive Applications

· Construction Applications · Healthcare Applications |

| Segment by Application | · Sheets

· Rolls · Blocks |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The NBR Foam Products market is set for significant growth, driven by increasing demand for thermal insulation and soundproofing solutions across various industries. As analyzed in the previous sections, the market’s growth potential is substantial, with the global market forecast to surpass $1.24 billion by 2025.

Future Prospects and Trends

The future of the NBR Foam Products market looks promising, with new formulations and technologies expected to drive innovation. Industry trends indicate a shift towards more energy-efficient and environmentally friendly products, aligning with global sustainability goals. The NBR Foam Products Market Outlook remains positive, with a steady Market Forecast and evolving Industry Trends.

As the construction, automotive, and HVAC industries continue to adopt NBR Foam Products for their insulation needs, manufacturers are likely to focus on developing products that meet strict regulatory requirements while enhancing performance. This will be crucial in shaping the Market Forecast and overall Industry Trends.

Global NBR Foam Products Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: NBR Foam Products Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- NBR Foam ProductsMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global NBR Foam Productsplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: NBR Foam Products Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: NBR Foam Products Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: NBR Foam Products Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofNBR Foam ProductsMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is driving the growth of the NBR Foam Products Market?

The growth of the NBR Foam Products Market is primarily driven by the increasing demand for thermal insulation in various industries, especially in the U.S. and Germany.

What are the key components of the NBR Foam Products supply chain?

The NBR Foam Products supply chain includes upstream and downstream components, involving key players such as manufacturers, suppliers, and distributors.

What are the major applications of NBR Foam Products?

NBR Foam Products are used in various industries, including HVAC, automotive, construction, and industrial insulation, providing thermal efficiency and sound insulation solutions.

What are the challenges facing the NBR Foam Products Market?

The market faces challenges related to regulatory constraints, raw material availability, and geopolitical factors impacting the supply of synthetic rubber.

How is the NBR Foam Products Market segmented?

The market is segmented based on density, thickness, and form, allowing for targeted marketing strategies and product development.

How do regional adoption trends impact the global NBR Foam Products market?

Regional adoption trends have a significant influence on the global market, as different regions exhibit varying demand patterns.

How are energy efficiency policies influencing the adoption of NBR Foam Products?

Energy efficiency policies, such as those in Japan, are driving the adoption of NBR Foam Products, promoting energy-efficient solutions.

What are the emerging trends in NBR Foam Products technology?

The market is seeing the rise of new formulations and technologies, creating chances for innovation and growth.

What is the competitive landscape of the insulation product manufacturing industry?

The industry is highly competitive, with manufacturers employing various strategies to gain a competitive edge.

What is the outlook for the NBR Foam Products Market?

The market is expected to experience significant growth, driven by increasing demand for thermal insulation and energy-efficient solutions. This trend is visually represented in the following image: .