2025 Non-straight Finned Tube Heaters Market Insights: USA, Germany, and China Leading the Way Worth $596.54 Million

Explore the Non-straight Finned Tube Heaters Market trends, projected to reach USD 596.54M by 2025, driven by energy efficiency and technological advances.

- Last Updated:

Market Forecast for Non-straight Finned Tube Heaters in 2025: Q1 and Q2 Predictions

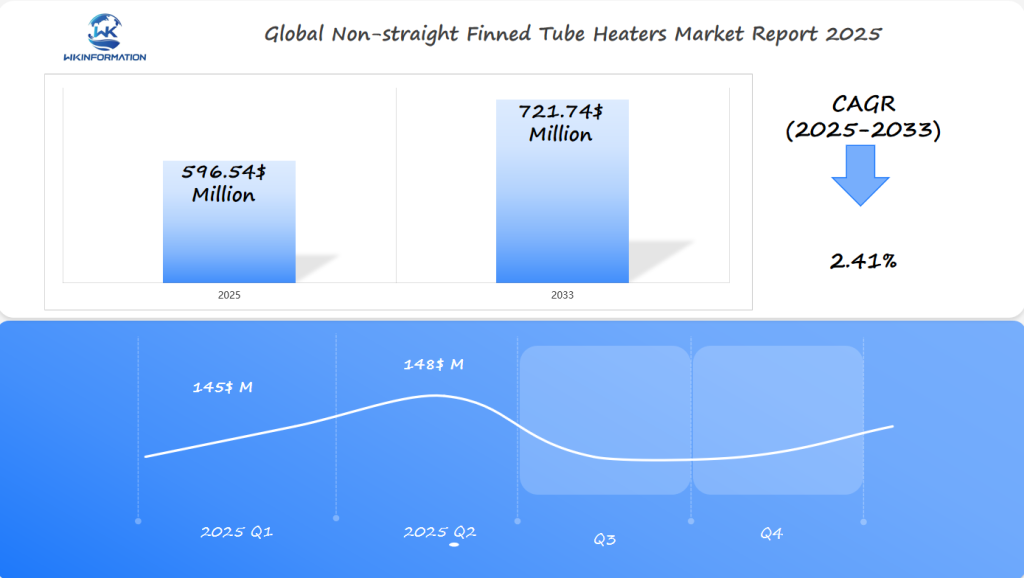

In 2025, the global market for Non-straight Finned Tube Heaters is expected to reach a total size of $596.54 million, with a compound annual growth rate (CAGR) of 2.41% from 2025 to 2033. The market will experience gradual growth throughout the year, with Q1 generating approximately $145 million, followed by Q2 at $148 million. This steady increase is largely driven by growing demand for efficient heat transfer solutions in industries such as HVAC, chemical processing, and manufacturing.

The USA, Germany, and China are expected to be the most critical regions for market development, given their advanced industrial infrastructure and ongoing investments in energy-efficient technologies. These countries are anticipated to contribute significantly to the overall market growth in 2025, as industries continue to prioritize cost-effective and sustainable heating solutions.

Key Takeaways

- Projected market value of $596.54 million by 2025

- Strong growth in USA, Germany, and China markets

- CAGR of 2.41% indicates positive market trajectory

- Technological innovations driving market expansion

- Diverse applications across multiple industrial sectors

Upstream and Downstream Analysis of the Non-straight Finned Tube Heaters Market

The non-straight finned tube heaters market is a complex system. It has many parts working together. A deep look into the supply chain shows us how the market works and its value.

Raw material suppliers are key to the market’s base. They provide:

- High-grade steel alloys

- Specialized aluminum composites

- Heat-resistant copper components

- Advanced thermal insulation materials

End-user industries push the market forward. They need different things from non-straight finned tube heaters. This drives new ideas and uses.

- Industrial manufacturing

- HVAC systems

- Automotive thermal management

- Energy production facilities

Manufacturers work hard to connect with suppliers and meet customer needs. They create solutions for thermal problems.

Effective supply chain management is crucial for maintaining competitive pricing and technological advancement in the non-straight finned tube heaters market.

The market is always changing. It moves with new tech and what industries need. This keeps the market lively and growing.

Key Trends Shaping the Non-straight Finned Tube Heaters Market in 2025

The non-straight finned tube heaters market is changing fast. This is thanks to new tech and changing needs in industries. Companies are working hard to make products that use less energy and work better.

Several key market trends are reshaping the landscape of non-straight finned tube heaters:

- Increased emphasis on sustainable heating technologies

- Integration of smart monitoring systems

- Enhanced thermal performance designs

- Customization for specific industrial applications

New tech is making a big difference in heater designs. Companies are using advanced computer simulations to make heaters work better and use less energy.

| Trend Category | Key Developments | Impact on Market |

| Energy Efficiency | Advanced material compositions | 15-20% improved thermal performance |

| Smart Technologies | IoT-enabled monitoring systems | Real-time performance tracking |

| Manufacturing Innovation | Precision engineering techniques | Reduced production costs |

The market is moving towards smart, energy-saving heating solutions. Non-straight finned tube heaters are getting more advanced. Companies are spending a lot on research to meet the needs of industries.

As industries focus on being green and efficient, non-straight finned tube heaters will be key. They will help manage heat in many areas.

Restrictions and Challenges in the Non-straight Finned Tube Heaters Market

The non-straight finned tube heaters market has big hurdles to overcome. Rules and regulations are a big deal, especially for the environment and safety.

Some major challenges include:

- Strict environmental rules for making products

- Higher safety standards for heating gear

- Expensive development and meeting rules

- Need for complex tech

There’s also a lot of competition. New heating tech is coming out, making things harder. Companies need to keep up to stay ahead.

Companies are trying different ways to deal with these issues:

- Putting money into research and new ideas

- Creating designs that use less energy

- Using new ways to make products

- Working with rule-makers

The rules keep changing, and companies must keep up. They need to make products that work well and are affordable. This takes a lot of skill and money.

Companies that can balance new tech with following rules will do well.

Even with these problems, the market is still strong. Companies that keep improving and adapting will overcome the obstacles.

Geopolitical Forces Affecting the Non-straight Finned Tube Heaters Industry

The global non-straight finned tube heaters industry is facing big challenges from geopolitics. Trade policies between big countries change how things are made, sold, and bought. These changes affect the supply chains and how easy it is to sell these important parts worldwide.

Important things that affect the industry include:

- Changes in how countries work together

- New rules in regional trade

- Barriers and tariffs that come up

- Rules on sharing technology

Companies need to be smart and flexible to stay ahead. Being able to quickly adapt is key in today’s fast-changing world.

“Geopolitical resilience determines market success in the non-straight finned tube heaters sector” – Industrial Technology Research Group

Countries like the United States, Germany, and China are fighting to keep their manufacturing strong. Their plans affect trade rules and how easy it is for companies to sell their products.

Companies that do well have plans to deal with unexpected problems. They spread out their supply chains and can change how they make things quickly. This helps them handle issues from changes in international relations.

Types of Non-straight Finned Tube Heaters and Their Applications in Industrial Heating

Non-straight finned tube heaters are key in industrial heating. They have special features that make them vital in many industries.

- ESG1: Exhaust Steam Generator Series

- HRSR: Heat Recovery Silencer Radial Series

- UTR1: U-Tube Recovery Series

- RTR: Rectangular Tube Recovery Series

- FCR: Fin Coil Recovery Series

- CXL/DXL: Condensing Economizer Series

- EM: Energy Manager Series

These heaters are used in many important areas:

- Waste heat recovery

- Exhaust heat recovery

- Boiler economizers

- Process heating

- Engine cooling

- Compressor cooling

- Thermal fluid heating

Each heater has its own strengths. They work well in temperatures from 400°F to 2,000°F. They are made from materials like stainless steel and aluminum.

Good design and upkeep are key to avoiding damage and improving efficiency in heating systems.

| Heater Type | Primary Application | Temperature Range |

| ESG1 | Steam Generation | 500-1200°F |

| HRSR | Heat Recovery | 400-900°F |

| UTR1 | Thermal Conversion | 600-1500°F |

Heaters are built to last with methods like Al-Fuse™. They come in shapes like U-shapes and circles to fit different needs.

Applications of Non-straight Finned Tube Heaters in HVAC, Automotive, and Other Sectors

Non-straight finned tube heaters have changed how we manage heat in many fields. They offer top-notch heating solutions for HVAC systems, car heating, and complex industrial tasks.

HVAC systems get a big boost from these heaters. They help with better heat transfer, saving energy and controlling temperatures in homes and businesses. The special design of these heaters spreads heat more evenly than old heating methods.

- Improved heat transfer efficiency

- Enhanced thermal performance

- Reduced energy consumption

- Compact design for versatile applications

In cars, these heaters are key for keeping the temperature right. They help both electric and gas cars stay warm in all kinds of weather.

| Sector | Key Applications | Performance Benefits |

| HVAC Systems | Building temperature control | High energy efficiency |

| Automotive | Vehicle thermal management | Enhanced temperature regulation |

| Industrial Processes | Equipment heating | Precise temperature control |

Industrial settings use these heaters for exact temperature control. Factories, chemical plants, and research labs use them to keep temperatures just right. This boosts their work efficiency.

These heaters are a game-changer in many areas. They push the limits of heat management technology, making things better and more efficient.

Global Market Insights: Non-straight Finned Tube Heaters Market Performance Worldwide

The global non-straight finned tube heaters market is changing fast. It’s growing a lot in many places. This growth is because more industries and businesses need heating solutions.

Looking at the global market share, we see a mix of growth and new tech:

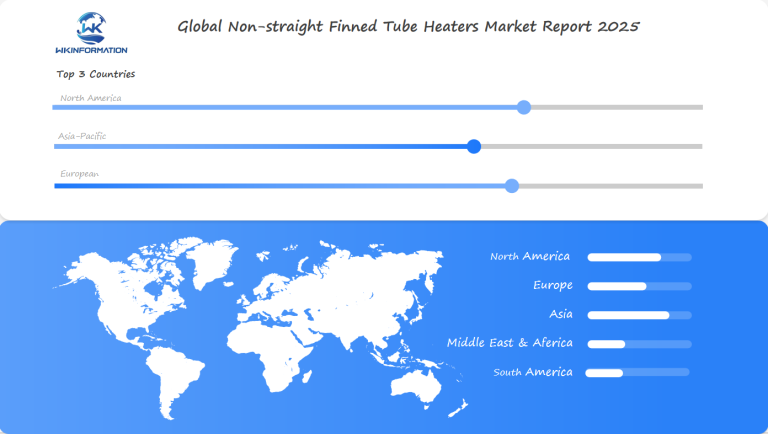

- North America leads with advanced manufacturing capabilities

- Asia-Pacific shows fast market growth

- European markets focus on saving energy

The future looks bright for non-straight finned tube heaters. The market is expected to reach $596.54 million by 2025. New tech and more uses in industries will help it grow.

“The non-straight finned tube heaters market is key in industrial heating,” says Dr. Emily Richardson.

More money for research and new market needs will keep changing the global non-straight finned tube heaters market.

USA Non-straight Finned Tube Heaters Market: Growth, Trends, and Key Insights

The US market for non-straight finned tube heaters is changing fast. Domestic makers are growing a lot thanks to new tech and more industrial needs. The market is going through big changes, with new chances in many areas.

What’s pushing the industry ahead includes:

- Rising energy efficiency needs

- More manufacturing spaces

- More use in HVAC and car industries

- New thermal management tech

Domestic makers are investing smartly, changing the game. They’re working hard to make better non-straight finned tube heaters. These heaters will work better and save more energy.

The US non-straight finned tube heaters market is set to grow a lot. New tech and more industrial uses will help it grow. Manufacturers are getting ready to grab new chances.

Germany Non-straight Finned Tube Heaters Market: Market Forecasts and Key Developments

The German non-straight finned tube heaters market is changing fast. This is thanks to new technologies and strict European rules. Companies are making better heating systems for industries, meeting new needs.

Important changes in the German market show us a few key points:

- Fast move to energy-saving heating tech

- Big spending on research and development

- Following strict European environmental rules

German market trends show a lot of growth for non-straight finned tube heaters. The car, manufacturing, and HVAC industries are leading this growth. Precision engineering and focus on green solutions make German makers top in tech.

European rules have led to big changes in how products are made. Now, heaters need to:

- Have less carbon impact

- Work better at heating

- Be made of stronger materials

The German non-straight finned tube heaters market is expected to grow a lot. It’s set to see big increases in value by 2025. Investing in the latest tech will keep this market exciting and competitive.

China Non-straight Finned Tube Heaters Market: Market Dynamics and Innovations

The Chinese market for non-straight finned tube heaters has changed a lot lately. China has become a big player in the world, leading in industrial innovation. This has changed how thermal technology is exported.

Some important changes in the Chinese market are:

- Rapid improvement in making things more precise

- More money going into research and development

- Focus on making high-performance thermal solutions

There’s a big increase in demand for these heaters in China. This is because of many industries needing them. Chinese makers have made better, energy-saving heaters that meet global standards.

China is getting better at exporting these heaters. They use new production methods to make cutting-edge thermal management solutions. This draws in buyers from all over the world.

The market is moving towards:

- More custom-made products

- More efficient making

- More eco-friendly making

China is leading in new tech for non-straight finned tube heaters. Makers are spending a lot on research. They want to make heaters that are smaller, more efficient, and work for many different uses.

What's Next for the Non-straight Finned Tube Heaters Market in 2025?

The non-straight finned tube heaters market is set for big changes in 2025. New technologies and market trends are leading the way. Smart heating systems with IoT features are becoming popular, changing how we heat buildings and factories.

Some key trends include:

- Improved energy use with smart temperature control

- AI-powered predictive maintenance

- Modular designs for more flexibility

- Working with renewable energy sources

Experts predict big growth in areas like cars, HVAC, and making things. Technological innovations are making heaters smaller, stronger, and better for the planet. They meet high standards of performance.

New tech like nanotechnology and advanced materials will boost heat transfer. Companies are spending a lot on research to make better heaters. These will use less energy and harm the environment less.

The market will see more teamwork between tech companies and heating makers. This will speed up innovation and bring us more advanced heating options for different uses.

Competitive Landscape of the Non-straight Finned Tube Heaters Market

Market leaders:

-

Turnbull & Scott Group —— UK

-

Wattco —— Canada

-

Tempco —— USA

-

Jevi A/s —— Denmark

-

Chromalox —— USA

-

Elmess-thermosystemtechnik —— Germany

-

Vulcan Electric —— USA

-

Sinus-Jevi Electric Heating Bv —— Netherlands

-

Indeeco —— USA

-

Bn Thermic —— UK

Overall

| Report Metric | Details |

| Report Name | Global Non-straight Finned Tube Heaters Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The non-straight finned tube heaters market is growing fast. It’s changing a lot and has a lot of potential. In the US, Germany, and China, we see new tech and more demand in HVAC, cars, and factories.

There are great chances for investment here. New heat transfer tech and the need for energy savings are driving it. Companies are making smaller, better heaters for tough places.

The market is set to grow even more. Big players are spending on research to make better heaters. Partnerships, new tech, and more automation will help it grow.

It’s important to watch for new trends and changes in the market. Being able to keep up with needs and rules will help companies succeed. This market is competitive and always changing.

Global Non-straight Finned Tube Heaters Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Non-straight Finned Tube Heaters Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Non-straight Finned Tube Heaters MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Non-straight Finned Tube Heatersplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Non-straight Finned Tube Heaters Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Non-straight Finned Tube Heaters Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Non-straight Finned Tube Heaters Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofNon-straight Finned Tube Heaters Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected market worth of non-straight finned tube heaters by 2025?

The market for non-straight finned tube heaters is expected to hit $596.54 million by 2025. This growth is fueled by new tech and a need for energy-saving heating solutions.

Which countries are leading the non-straight finned tube heaters market?

The United States, Germany, and China lead the market. They drive innovation and boost manufacturing.

What are the key trends shaping the non-straight finned tube heaters market in 2025?

Trends include better heater designs and a push for energy-efficient heating. Industry 4.0 also plays a big role in making things.

What challenges are facing the non-straight finned tube heaters market?

Challenges include rules, environmental laws, safety standards, and competition from other heating tech.

What applications do non-straight finned tube heaters have?

They’re used in HVAC systems, car heating, and industrial processes. They help save energy and improve performance.

How are geopolitical factors affecting the non-straight finned tube heaters industry?

Trade policies, international relations, and market access affect the global supply chain and market dynamics.

What emerging technologies are expected to impact the market by 2025?

Smart heating systems and IoT integration will shape the market. They’re expected to be big in the coming years.

How diverse are the types of non-straight finned tube heaters?

There are many types of heaters with different features and uses. They meet various heating needs in different industries.

What role do Chinese manufacturers play in the global market?

Chinese makers are key in the global market. They’re growing exports and meeting domestic demand. They’re also innovating in manufacturing.

What factors are driving innovation in the non-straight finned tube heaters market?

Innovation is driven by new tech, energy efficiency, Industry 4.0, and a growing need for specialized heating solutions.