One Way Degassing Valve Market Forecasted to Surpass $175.2 Million by 2025: Packaging Innovation in China, the U.S., and Italy

Explore the expanding One Way Degassing Valve Market as it revolutionizes coffee packaging solutions, driving growth through increased demand for freshly roasted coffee products globally.

- Last Updated:

One Way Degassing Valve Market Q1 and Q2 of 2025

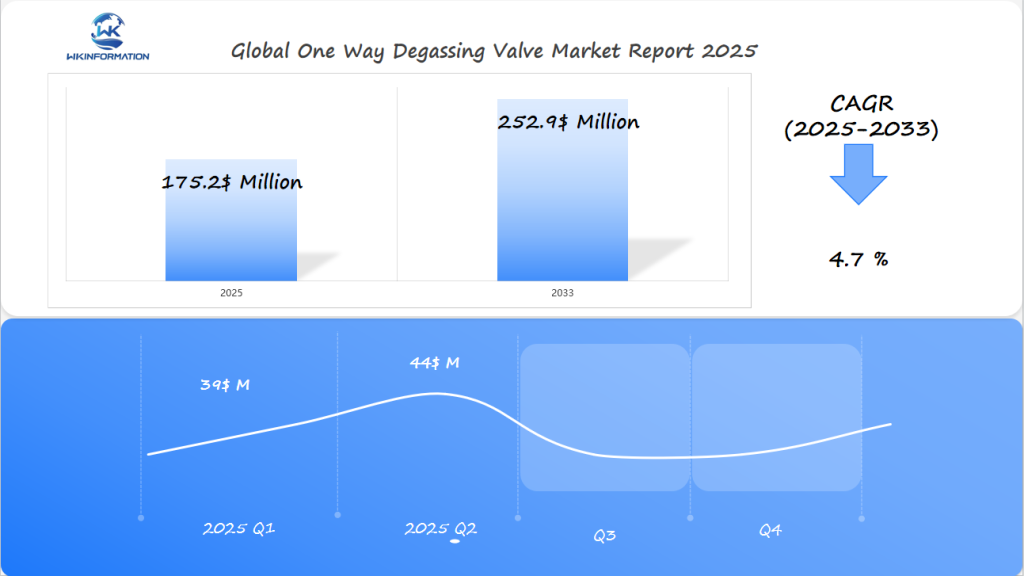

The One Way Degassing Valve market is set to reach $175.2 million by 2025, with a projected CAGR of 4.7% from 2025 to 2033. In Q1 2025, revenue is expected to be around $39 million, growing to nearly $44 million in Q2, driven by rising demand in food packaging, particularly for coffee and dry goods.

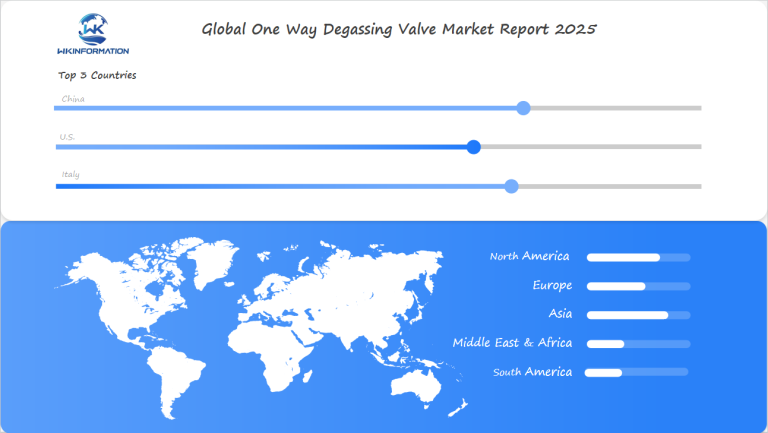

The functionality of degassing valves in maintaining freshness and extending product shelf life is increasingly valued in both premium and mass-market segments. China, the U.S., and Italy lead the market, thanks to their strong packaging manufacturing bases, consumer goods export activity, and innovative adoption of pressure-sensitive valve technologies.

Key Takeaways

- The global market is projected to reach $175.2 million by 2025.

- Packaging innovation is driving technological advancements.

- There is an increasing demand across coffee, food, and industrial sectors.

- China and the U.S. are leading market development.

- There is a growing focus on product quality and shelf life preservation.

Upstream and Downstream Integration in the One Way Degassing Valve Supply Chain

The world of valve making has changed a lot thanks to better supply chain work. Big names in packaging are now thinking differently about making, selling, and getting one way degassing valves out there.

Supply chain work is key for new ideas in valve making. Companies like Goglio S.p.A. and Syntegon are leading the way. They’re working together to link up suppliers with packaging teams.

Upstream Integration

Upstream integration focuses on raw material sourcing and design optimization. This means that valve makers are looking for ways to get their materials directly from suppliers and improve the design of their products at the same time.

Downstream Integration

Downstream integration emphasizes collaborative product development. This involves working closely with packaging teams to create products that meet their specific needs and requirements.

Strategic Partnerships

Strategic partnerships enable faster market responsiveness. By partnering with other companies in the supply chain, valve makers can quickly adapt to changes in the market and deliver their products more efficiently.

The packaging world wants better degassing valves. This has made valve makers work harder on their integration plans. They’re making things better, using less, and making products that are top-notch.

They’re also using new tech to talk and share data all along the supply chain. This digital shift helps with:

- Predictive maintenance of manufacturing equipment

- Enhanced quality control mechanisms

- Rapid prototyping and design iterations

The future of valve making is about making supply chains that work together well. They need to be able to change fast to meet new market needs.

Emerging Trends in Coffee Packaging, Food Safety, and Valve Design

The one-way degassing valve market is changing fast. New coffee packaging trends and food safety tech are leading the way. Companies are working hard to meet consumer demands and solve big problems.

New valve designs are making a big difference. They help keep coffee and other goods fresh and of high quality. The shift towards smarter, greener packaging is clear.

Sustainable Materials and Smart Packaging Solutions

There is now a greater emphasis on using eco-friendly materials. This helps minimize damage to the environment. Some significant advancements include:

- Biodegradable valve components

- Recyclable packaging materials

- Compostable valve designs

- Plant-based polymer technologies

Enhanced Barrier Properties and Improved Flow Rates

Food safety is getting a boost from new valve tech. Companies are making valves that block more gas and flow better.

| Valve Design Feature | Performance Improvement | Industry Impact |

| Micro-perforated membranes | 90% gas release efficiency | Extended product freshness |

| Multi-layer barrier materials | Increased shelf life by 40% | Reduced food waste |

| Smart sensor integration | Real-time quality monitoring | Enhanced food safety |

The coffee packaging world is leading the way in these changes, driving the entire one-way degassing valve market forward. Increased funding for research and development will bring even more innovative ideas to packaging.

Regulatory Constraints and Raw Material Supply Pressures

The one-way degassing valve market is facing big challenges. These come from changing food safety rules and the cost of raw materials. Companies need to find new ways to meet strict packaging standards and use materials in a way that’s good for the planet.

Some big challenges for the industry include:

- Strict food safety regulations requiring advanced packaging technologies

- Environmental compliance mandates for sustainable material use

- Increased scrutiny of packaging material composition

Raw material supply chains are very unstable. Companies must deal with changing costs and keep making high-quality valves.

The economic situation is tough for valve makers. Costs for special plastics and advanced packaging parts are going up. This pushes companies to get creative with their designs and how they make things.

| Regulatory Area | Impact on Valve Manufacturing | Required Adaptation |

| Food Safety Standards | Stricter material restrictions | Advanced filtering technologies |

| Environmental Regulations | Reduced plastic usage | Bio-based material research |

| Quality Control | Enhanced testing requirements | Comprehensive quality management |

Innovative companies are working on next-generation degassing valve solutions. They aim to meet rules while keeping costs down and production efficient.

Geopolitical Factors Affecting Valve Export and Import Routes

The world of global trade for one way degassing valves is complex. Recent data shows that valve exports hit USD 106 billion in 2022. This makes valves the 30th most traded item globally.

Trade rules for valves vary by country, affecting how they move across borders. Key factors include:

- Tariff structures

- Regional economic partnerships

- Technological transfer restrictions

- Intellectual property regulations

Big players like China, the United States, and European countries lead in valve exports. Political tensions can mess up supply chains. This forces makers to find stronger ways to trade internationally.

Emerging markets are becoming key in the valve trade world. Companies face tough rules when importing. They must keep prices low and quality high, meeting international standards.

Global trade is all about adapting. Makers and exporters need to stay quick, watching for changes that could affect their trade paths and markets.

Type-Based Market Segmentation: PE Valves, Composite Valves, Bio-Based Valves

The one way degassing valve market is complex, with different types of valves. PE valves lead in packaging, thanks to their strong performance in various industries. Companies are now creating new valve designs to fit different needs.

Key valve types in the market include:

- PE (Polyethylene) Valves

- Composite Valves

- Bio-Based Valves

Circular valves are the most common, making up about 65% of the market. Square valves are becoming more popular, especially in flexible packaging. This is because they save space.

| Valve Type | Primary Applications |

|---|---|

| PE Valves | Coffee Packaging, Food Storage |

| Composite Valves | Industrial Packaging, Specialty Foods |

| Bio-Based Valves | Sustainable Packaging Solutions |

Bio-based valves are a new and exciting part of the market. They are made to be eco-friendly and are getting more attention. This is because people want packaging that is good for the planet.

Application Segments: Coffee, Pet Food, Powdered Goods, Industrial Uses

The one way degassing valve market covers many important areas. Each field has its own packaging problems. Coffee packaging is a big part of this, making up a lot of the demand for these valves.

New uses for degassing valves are growing in different fields:

- Coffee Packaging: Keeps the aroma fresh and stops oxidation

- Pet Food Industry: Keeps food fresh for longer

- Powdered Goods: Controls moisture and pressure in sealed bags

- Industrial Applications: Meets complex packaging needs

The food and drink industry uses the most of these special valves. Coffee packaging shows the most advanced use of valves. These valves help keep coffee beans fresh from roasting to drinking.

| Application Segment | Key Packaging Challenge |

|---|---|

| Coffee Packaging | Oxygen and moisture control |

| Pet Food Industry | Freshness preservation |

| Powdered Goods | Pressure regulation |

| Industrial Applications | Specialized barrier protection |

New trends show more interest in pet food and industrial uses. Companies are making better valve technologies to protect products better.

Understanding the Global Market for Degassing Valves

The market for one-way degassing valves is complex, with different regions having their own needs and manufacturers tailoring their products accordingly. Valve makers employ smart strategies to serve markets all over the world.

What Makes Each Region Unique?

Here are some key factors that differentiate each region:

- North America has a focused market with cutting-edge technology

- Europe values high-quality and eco-friendly packaging

- Asia-Pacific has a varied manufacturing scene

How Different Regions Manufacture Valves

Each region has its own approach to valve manufacturing:

- North American valve makers focus on the latest technology

- Asian producers aim for low costs

- Europeans lead in precision and green design

Getting Valves to Customers Worldwide

Distributing valves to customers around the world is a significant task. Manufacturers use specific plans to meet the demands of each area, taking into account:

- Following local regulations

- Understanding buyer preferences in packaging

- Exploring options for local valve production

- Managing shipping and delivery logistics

The distribution landscape for valves is constantly evolving, highlighting the importance of flexibility for manufacturers to succeed in diverse markets.

China's Production Dominance and Export Leverage in the Valve Industry

China has become a leader in the one-way degassing valve market. It has leveraged its strong manufacturing capabilities to lead global exports. The country’s smart approach to manufacturing valves has placed it at the top of international packaging technology.

Chinese valve production has several key strengths:

- Advanced manufacturing infrastructure

- Cost-effective production processes

- Rapid technological innovation

- Scalable export markets

The markets for Chinese valves have grown a lot. In 2022, they reached an impressive USD 22.9 billion in exports. This shows China can meet the world’s need for top-notch packaging solutions in many industries.

China’s valve making has been boosted by new tech. Companies have put a lot of money into research and development. This has led to advanced one-way degassing valves that meet global quality standards.

These innovations help Chinese companies compete well in the world market. They do especially well in coffee packaging and specialty foods.

Chinese makers have also formed key partnerships and improved their production methods. This has helped them overcome past challenges. Now, they offer top-notch valve solutions that are both effective and affordable, while also caring for the environment.

U.S. Demand Driven by Specialty Coffee and Sustainable Packaging

The US coffee market is growing fast, thanks to specialty coffee. This growth is driving new packaging technologies. Degassing valves are key for keeping coffee fresh and improving the customer experience.

Now, the specialty coffee industry is focusing on environmentally friendly packaging. This shift has made one-way degassing valves increasingly popular. Coffee brands want to keep coffee fresh and protect the planet.

Key Highlights

- Specialty coffee consumption has increased by 20% in the past three years

- Sustainable packaging solutions are becoming a key differentiator for brands

- One-way degassing valves are essential for maintaining coffee quality

Market trends show how important new packaging is:

| Market Segment | Key Driver |

|---|---|

| Specialty Coffee Packaging | Consumer Demand |

| Sustainable Valve Technologies | Environmental Awareness |

| Premium Coffee Packaging | Quality Preservation |

New valve technologies are changing coffee packaging. They focus on keeping coffee fresh and reducing waste.

The U.S. coffee market leads the way in packaging innovation. Companies are investing heavily in advanced degassing valves. These valves meet consumer demands and help protect the environment.

Italy's Innovation Focus in Valve Design for Premium Applications

Italy leads in coffee innovation, especially in one-way degassing valve tech. Its deep coffee culture fuels big leaps in premium packaging. This tech changes how coffee is kept fresh and of high quality.

Italian valve design is a top example of engineering skill. Companies have created new tech to solve big problems in coffee packaging. They focus on:

- Keeping moisture out

- Getting gas out right

- Using eco-friendly materials

The Italian way of improving coffee packaging stands out for its focus on details. Companies like Goglio S.p.A. have made valves that keep coffee’s taste and freshness longer.

| Innovation Aspect | Key Characteristics |

| Material Selection | High-performance polymers |

| Design Complexity | Precision micro-engineering |

| Performance Metrics | Superior gas release efficiency |

These Italian valve design breakthroughs show why Italy is a top name in coffee packaging tech. Italian makers keep setting new standards. They make sure coffee stays fresh and top-notch.

Future Market Evolution and Smart Valve Integration Forecast

The global one-way degassing valve market is set for a big change. Future Market Insights predicts a huge growth. By 2037, the market is expected to hit a big value, thanks to smart packaging and IoT.

Key Changes in Valve Technology

New trends in valve technology are changing packaging. Key changes include:

- Advanced sensor-enabled degassing valves

- Real-time freshness monitoring systems

- AI-powered quality control mechanisms

Smart packaging is changing how we keep products fresh and interact with them. Intelligent degassing valves now do more than just release gas. They give detailed product info through tech integration. IoT lets makers track products from start to finish, ensuring quality and safety.

Investment in Research for New Valve Technology

Companies are spending a lot on research for new valve tech. They want to make products more sustainable, efficient, and meet consumer needs. The mix of nanotechnology, AI, and advanced materials is opening up new chances in the degassing valve market.

Businesses that use these new tech will likely stay ahead in a more complex packaging world.

Competitive Benchmarking and OEM/ODM Presence in the Valve Market

The one way degassing valve market is very competitive. Global OEM manufacturers and ODM partnerships are fighting for market share. They use new designs and advanced manufacturing to stand out.

Key Players:

- Fres-co System USA — USA

- Chemvalve — USA

- WITT-GASETECHNIK GmbH & Co KG — Germany

- Goglio S.p.A. — Italy

- TedPack — China

- TricorBraun Flex — USA

- CCL Industries — Canada

- Syntegon — Germany

- Wojin Plastic Product Factory — China

- Wipf — Switzerland

Prominent companies driving the competitive landscape include:

- Goglio S.p.A. – European packaging innovation leader

- Wipf – Swiss precision engineering specialist

- Wojin Plastic Product Factory – Chinese manufacturing powerhouse

- Syntegon – Advanced packaging technology provider

- TricorBraun Flex – Flexible packaging solutions expert

OEM manufacturers are working hard to create better valve technologies. These technologies help keep products fresh longer. The market is seeing important strategies:

- Invest in research and development

- Create strategic ODM partnerships

- Develop sustainable packaging solutions

- Expand globalmanufacturing capabilities

The competitive landscape continues to evolve, with companies seeking differentiation through technological innovation and strategic collaborations. ODM partnerships are key for manufacturers. They help speed up product development and get products to market faster.

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global One Way Degassing Valve Market Report |

| Base Year | 2024 |

| Segment by Type |

· PE (Polyethylene) Valves · Composite Valves · Bio-Based Valves |

| Segment by Application |

· Coffee Packaging · Pet Food Industry · Powdered Goods · Industrial Applications · Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The One Way Degassing Valve market is growing fast, offering great chances for smart investors. It’s expected to grow at a 4.7% Compound Annual Growth Rate (CAGR) until 2034. The market value is set to hit USD 2.81 billion. There are big opportunities in green packaging and new valve designs in many fields.

Technology is leading the market’s growth. Companies making specialty coffee and food are looking for better degassing valves. These valves help keep products fresh and of high quality. Smart packaging is key, combining new materials and designs.

Looking at different markets, China, the United States, and Europe show great potential. The focus on green materials is a big growth area. Investors can make good money by backing innovations that are good for the planet and keep packaging high-quality.

Investors should spread their bets across different valve tech areas. They should focus on research in eco-friendly materials, new polymers, and smart packaging. The market will favor those who invest in tech and meet consumer needs.

Global One Way Degassing Valve Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: One Way Degassing Valve Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- One Way Degassing Valve Market Segmentation Overview

Chapter 2: Competitive Landscape

- Global One Way Degassing Valve Players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: One Way Degassing Valve Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: One Way Degassing Valve Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: One Way Degassing Valve Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of One Way Degassing Valve Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is a One Way Degassing Valve?

A one way degassing valve lets gases out of packaged items like coffee. It stops air from getting in. This keeps the product fresh and prevents the package from getting too full.

Why are One Way Degassing Valves critical for coffee packaging?

One Way Degassing Valves are key for coffee packaging. They let out carbon dioxide from coffee beans. This keeps the coffee’s flavor and aroma good and stops the package from bursting.

What materials are typically used in manufacturing One Way Degassing Valves?

Polyethylene (PE), composite materials, and bio-based polymers are often used. Each has its own benefits, like cost, performance, and being good for the environment.

How do One Way Degassing Valves contribute to food safety?

These valves keep food quality high by stopping moisture and contaminants from getting in. They let gases out, which helps prevent bacteria and keeps the food’s taste and smell good.

Which industries primarily use One Way Degassing Valves?

One Way Degassing Valves are primarily used in the following industries:

- Coffee

- Pet food

- Powdered goods

- Specialty foods

- Industrial applications

These industries require precise control over gas release and package protection.

What are the key technological advancements in One Way Degassing Valve design?

New advancements include better barrier properties and flow rates. There’s also smart tech like IoT sensors and more eco-friendly materials.

How do geopolitical factors impact the One Way Degassing Valve market?

Trade policies, tariffs, and economic partnerships affect valve production and sales. Countries like China, the U.S., and Italy play big roles.

What drives the growth of the One Way Degassing Valve market?

The growth of the One Way Degassing Valve market is driven by several factors:

- Increasing demand for quality packaged goods

- Growing popularity of specialty coffee

- Emphasis on food safety and hygiene

In addition to these factors, other drivers of market growth include:

- Continuous innovation in packaging solutions

- Rising consumer preference for eco-friendly and sustainable packaging options

Are there environmental considerations in One Way Degassing Valve production?

Yes, makers focus on eco-friendly materials and reducing waste. They aim to use bio-based alternatives to traditional plastics.

What challenges do manufacturers face in the One Way Degassing Valve market?

Makers face tough food safety rules, price changes, and the need for new ideas. They also have to keep up with what consumers want and stay competitive globally.