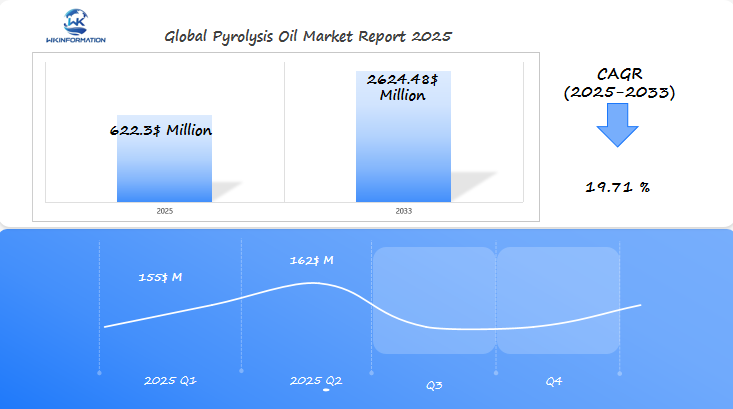

Pyrolysis Oil Market to Reach $622.3 Million by 2025: Explosive Growth Driven by the U.S., India, and Japan

Discover the explosive growth potential of the pyrolysis oil market as it reaches $622.3 million by 2025. Explore how the U.S., India, and Japan are driving innovation and expansion in this sustainable energy sector, with technological breakthroughs and strategic market developments shaping its future.

- Last Updated:

Pyrolysis Oil Market Q1 and Q2 2025 Forecast

The Pyrolysis Oil market is expected to reach $622.3 million in 2025, with an impressive CAGR of 19.71% from 2025 to 2033. In Q1 2025, the market is projected to generate approximately $155 million, driven by the increasing use of renewable energy sources and growing interest in waste-to-energy technologies. The market will be particularly strong in the U.S., India, and Japan, where interest in sustainable fuels and environmentally friendly energy alternatives is growing.

By Q2 2025, the market will likely reach $162 million, as the adoption of pyrolysis oil accelerates due to its potential to reduce reliance on fossil fuels. The expansion of waste management and bioenergy initiatives, along with favorable government policies for sustainable energy solutions, will contribute to rapid market growth. India and Japan will be key players in utilizing pyrolysis oil for industrial applications and energy production.

Understanding the Upstream and Downstream Factors in Pyrolysis Oil

The supply chain of pyrolysis oil involves complex components both before (upstream) and after (downstream) the production process. These components influence how the market operates and how efficient the production is.

Upstream Factors

The following factors play a crucial role in the production of pyrolysis oil:

1. Biomass Resources

- Agricultural waste

- Forest residues

- Municipal solid waste

- Industrial organic waste

2. Collection Infrastructure

- Local waste management systems

- Agricultural collection networks

- Industrial partnerships

The quality and availability of these raw materials directly impact production costs and final product specifications. Seasonal variations in biomass availability create supply fluctuations, requiring strategic inventory management.

Downstream Factors

The distribution and application network includes:

1. Distribution Channels

- Direct industrial supply

- Bulk storage facilities

- Transportation networks

- Regional distribution centers

2. Key Application Sectors

- Power generation facilities

- Chemical manufacturing

- Industrial heating

- Transportation fuel blending

Market dynamics are shaped by:

Storage Requirements:

- Temperature-controlled facilities

- Specialized handling equipment

- Safety protocols

Quality Control:

- Standard compliance

- Product certification

- Performance testing

End-user Specifications:

- Industry-specific requirements

- Regional regulations

- Performance standards

The interaction between upstream and downstream forces creates unique market challenges. Supply chain optimization requires careful coordination between raw material suppliers, production facilities, and end-users. Companies investing in vertical integration gain competitive advantages through better control over quality and costs.

Recent technological advancements have improved production efficiency and product consistency. Advanced processing techniques allow for better handling of diverse feedstock sources, meeting specific end-user requirements across different sectors.

Top Trends Shaping the Future of the Pyrolysis Oil Market

The pyrolysis oil market is undergoing significant changes due to several important trends that are reshaping the industry. These developments indicate promising growth potential for those involved in the sector.

1. Sustainable Waste Management Integration

- Agricultural waste conversion into valuable pyrolysis oil

- Municipal solid waste processing capabilities

- Plastic waste recycling initiatives gaining traction

2. Technological Breakthroughs

- Advanced catalytic pyrolysis processes improving oil quality

- Real-time monitoring systems for optimal production control

- Enhanced storage solutions addressing stability issues

- Automated feeding systems reducing operational costs

3. Policy-Driven Market Growth

- Carbon credit programs incentivizing pyrolysis oil production

- Tax benefits for renewable energy investments

- Stricter regulations on conventional fuel emissions

4. Industry 4.0 Integration

- AI-powered process optimization

- IoT sensors for quality control

- Blockchain implementation in supply chain tracking

- Digital twin technology for plant operations

5. Market Adaptation Strategies

- Co-processing facilities with existing refineries

- Strategic partnerships between waste management companies

- Development of specialized transportation networks

6. Research and Innovation Focus

- Bio-oil upgrading technologies

- New feedstock exploration

- Improved catalyst development

- Enhanced storage stability solutions

The demand for cleaner fuels continues to drive innovation in pyrolysis technology. Recent developments include high-efficiency reactors capable of processing multiple feedstock types simultaneously. These advancements have resulted in higher-quality pyrolysis oil with improved stability characteristics.

Government policies promoting renewable energy sources have created favorable market conditions. Countries implementing green energy initiatives are establishing dedicated research centers focused on pyrolysis technology advancement. These facilities are pioneering new methods for bio-oil production and upgrading.

The integration of advanced analytics and automation has revolutionized production processes. Smart factories utilizing machine learning algorithms optimize production parameters in real-time, resulting in increased yields and reduced operational costs.

Addressing the Key Challenges in the Pyrolysis Oil Industry

The pyrolysis oil industry faces significant technical and operational hurdles that impact market growth and widespread adoption. These challenges require innovative solutions and strategic approaches to ensure sustainable industry development.

Production Process Complexities

- High viscosity issues during oil storage and transportation

- Thermal instability leading to changes in chemical composition

- Inconsistent product quality due to varying feedstock characteristics

- Complex reactor design requirements for optimal yield

Technical Barriers

- Limited shelf life of pyrolysis oil products

- Corrosive nature affecting storage and handling equipment

- Need for specialized catalysts and processing conditions

- High energy consumption during production

Regulatory and Market Challenges

- Strict environmental compliance requirements

- Lack of standardized quality parameters

- Limited infrastructure for large-scale production

- High initial capital investment needs

Cost-Related Issues

- Expensive pre-treatment processes for raw materials

- Maintenance costs for specialized equipment

- Competition from conventional fuel prices

- Research and development expenses

Proposed Solutions

Technology Enhancement

- Implementation of advanced catalyst systems

- Development of improved storage stabilization techniques

- Integration of automation for quality control

- Investment in corrosion-resistant materials

Market Development

- Creation of industry-wide quality standards

- Establishment of dedicated supply chains

- Formation of strategic partnerships

- Development of specialized transportation networks

The industry’s stakeholders are actively working on technological improvements to address these challenges. Research institutions and private companies are investing in advanced processing techniques and material science innovations to enhance production efficiency and product quality. These efforts, combined with growing market demand, signal positive developments in overcoming current industry limitations.

Geopolitical Factors Influencing Pyrolysis Oil Production

Global energy markets are highly affected by geopolitical tensions, which directly impact the development and adoption of alternative fuel sources like pyrolysis oil. The Russia-Ukraine conflict has reignited interest in energy independence, prompting countries to diversify their energy sources.

Key Geopolitical Influences on Pyrolysis Oil Markets:

- Trade restrictions and sanctions affecting traditional fossil fuel supply chains

- Political alliances shaping technology transfer and knowledge sharing

- Regional conflicts disrupting raw material supply routes

- Economic partnerships influencing market access and distribution

Countries with limited fossil fuel reserves are actively pursuing pyrolysis oil production to reduce their import dependence. This shift creates new power dynamics in the global energy landscape, as nations leverage their waste-to-energy capabilities.

Strategic Energy Independence Initiatives:

- Development of domestic pyrolysis facilities

- Investment in research and development programs

- Creation of supportive regulatory frameworks

- Formation of strategic partnerships with technology providers

The Middle East’s traditional oil-producing nations are diversifying their energy portfolios by investing in pyrolysis technology. These investments serve as hedging strategies against potential shifts in global energy demands.

Regional Energy Security Measures:

- North America: Focus on agricultural waste conversion

- European Union: Emphasis on plastic waste pyrolysis

- Asia-Pacific: Investment in municipal solid waste processing

- Middle East: Integration with existing petrochemical infrastructure

Cross-border tensions have prompted countries to establish domestic pyrolysis oil production capabilities. Japan’s recent investments in pyrolysis technology reflect its strategy to reduce dependence on imported energy sources. Similar patterns emerge in India, where agricultural waste conversion to pyrolysis oil addresses both energy security and environmental concerns.

The race for technological supremacy in pyrolysis oil production creates new diplomatic leverage points. Countries with advanced pyrolysis technology gain strategic advantages in international negotiations, while those lacking technical expertise seek collaborative partnerships to bridge the gap.

Key Insights on Pyrolysis Oil Market Segmentation

The pyrolysis oil market divides into two primary product categories: bio-oil and synthetic oil, each serving distinct industrial applications and market needs.

Characteristics and Applications of Bio-Oil

- Feedstock SourcesAgricultural residues

- Forest waste

- Municipal solid waste

- Primary UsesPower generation

- Industrial heating

- Transportation fuel blending

Properties and Uses of Synthetic Oil

- Raw Material Base Plastic waste

- Tire waste

- Industrial polymers

- Key Applications Chemical manufacturing

- Industrial lubricants

- Specialty fuels

Distribution of the Market by Region

North American Market

- Dominant in bio-oil production

- Strong focus on agricultural waste conversion

- Advanced technological infrastructure

- High demand in industrial heating sector

Asia-Pacific Dynamics

- Rapid growth in synthetic oil segment

- Rising demand for waste plastic conversion

- Industrial heating applications lead market share

- Emerging transportation fuel market

European Landscape

- Stringent sustainability regulations drive adoption

- Focus on municipal waste conversion

- Growing demand in chemical manufacturing

- Advanced research and development initiatives

The market segmentation reflects varying regional priorities and technological capabilities. North America leads in bio-oil production technology, while Asia-Pacific shows significant growth in synthetic oil development. European markets demonstrate balanced growth across both segments, driven by strict environmental regulations.

Regional demand variations stem from different industrial needs and regulatory frameworks. North American markets prioritize agricultural waste conversion, Asia-Pacific focuses on plastic waste management solutions, and European markets emphasize sustainable chemical production processes.

These distinct regional characteristics shape product development strategies and market penetration approaches for industry players. The segmentation patterns indicate a growing specialization trend, with regions developing expertise in specific pyrolysis oil types and applications.

In line with these trends, it’s worth noting that recent studies have highlighted the potential for further expansion in the pyrolysis oil market, driven by technological advancements and increasing environmental awareness.

How Applications are Fueling Pyrolysis Oil Demand

The diverse applications of pyrolysis oil create substantial market opportunities across multiple industries. Let’s examine the key sectors driving demand growth:

1. Power Generation

- Direct combustion in boilers and furnaces

- Co-firing with conventional fossil fuels

- Combined heat and power (CHP) systems

- Industrial steam production

2. Transportation Fuel Applications

- Blend stock for conventional diesel

- Marine fuel alternatives

- Aviation fuel development programs

- Heavy machinery fuel supplements

3. Chemical Industry Uses

- Raw material for bio-based chemicals

- Production of phenolic compounds

- Extraction of valuable chemicals

- Manufacturing of adhesives and resins

4. Industrial Heating Solutions

- Process heating applications

- Kiln operations

- Metal processing

- Glass manufacturing

The industrial sector demonstrates particularly strong demand growth, with manufacturers seeking cost-effective alternatives to traditional fossil fuels. The latest data shows some growth in the adoption of pyrolysis oil in industrial heating applications.

Research institutions and commercial entities are actively developing new applications. The chemical industry leads innovation, creating high-value products from pyrolysis oil components. These developments include specialized resins, bio-based plastics, and green chemicals.

Power generation remains the largest application area, accounting for less than half of the total pyrolysis oil consumption.This dominance stems from increasing renewable energy mandates and the push for cleaner power generation methods. Utility companies report significant cost savings when incorporating pyrolysis oil into their fuel mix.

The transportation sector presents emerging opportunities, particularly in marine applications where stricter emissions regulations drive the search for alternative fuels. Several shipping companies now run pilot programs testing pyrolysis oil blends in their vessels.

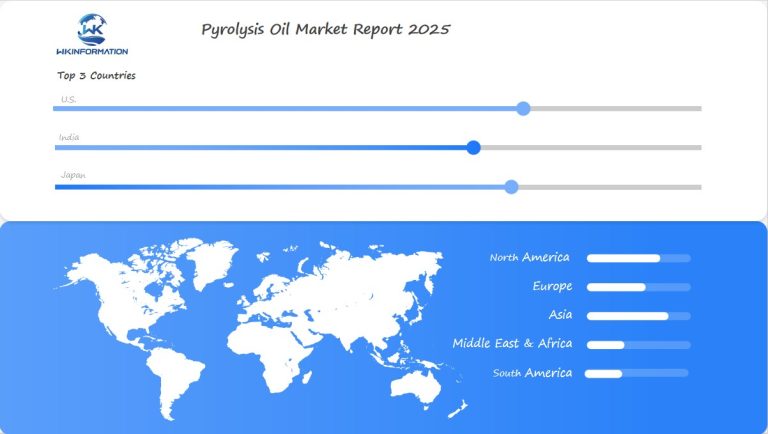

Global Regional Breakdown of the Pyrolysis Oil Market

The pyrolysis oil market exhibits distinct regional characteristics across different geographical zones:

1. North America

- Holds some market share

- Advanced technological infrastructure

- Strong regulatory framework supporting renewable energy

- High investment in R&D facilities

2. Europe

- Second-largest market contributor

- Strict environmental regulations driving adoption

- Focus on waste-to-energy conversion

- Leading in biomass pyrolysis technology

3. Asia-Pacific

- Fastest-growing region

- Rapid industrialization driving demand

- Agricultural waste management initiatives

- Emerging markets showing significant potential

4. Middle East and Africa

- Growing interest in waste management solutions

- Investment in renewable energy infrastructure

- Developing regulatory frameworks

- Rising focus on sustainable development

The market distribution reflects varying levels of technological advancement and regulatory support across regions. North America’s dominance stems from established infrastructure and substantial investment in sustainable technologies. Europe’s position is strengthened by stringent environmental policies and technological innovation. The Asia-Pacific region’s growth is fueled by rapid industrialization and increasing environmental awareness, while the Middle East and Africa show promising development through emerging sustainability initiatives.

U.S. Pyrolysis Oil Market: Key Growth Factors and Trends

The U.S. pyrolysis oil market shows strong potential for growth, driven by several key factors:

1. Advanced Infrastructure Development

- State-of-the-art processing facilities

- Extensive research and development capabilities

- Strong supply chain networks

2. Regulatory Support

- Implementation of the Renewable Fuel Standard (RFS) program

- Tax incentives for renewable energy producers

- State-level policies promoting clean energy adoption

The market benefits from strategic partnerships between technology providers and waste management companies. These collaborations create efficient waste-to-energy conversion systems, reducing landfill dependency while producing valuable pyrolysis oil.

3. Key Market Drivers

- Rising demand for sustainable aviation fuel

- Growing industrial need for bio-based chemicals

- Increasing corporate sustainability commitments

U.S. companies have pioneered innovative pyrolysis technologies, including mobile processing units and automated feedstock handling systems. These advancements reduce production costs and improve oil quality, making pyrolysis oil competitive with conventional fossil fuels.

The agricultural sector plays a crucial role, providing abundant biomass feedstock for pyrolysis oil production. Farmers benefit from additional revenue streams through agricultural waste conversion, creating a sustainable circular economy model.

Recent investments in pyrolysis facilities across states like California, Texas, and Illinois signal strong market confidence. These developments align with the national goal of reducing carbon emissions while fostering domestic energy independence.

India's Role in Pyrolysis Oil Development

The pyrolysis oil industry in India shows a huge growth potential and is expected to grow at a substantial CAGR in the next few years. The country’s unique position stems from its abundant agricultural residue and significant plastic waste generation, creating ideal conditions for pyrolysis oil production.

Key drivers propelling India’s pyrolysis oil market:

1. Agricultural Waste Management

- Converting crop residues into valuable pyrolysis oil

- Reducing environmental impact of stubble burning

- Creating additional income streams for farmers

2. Urban Waste Solutions

- Transforming municipal solid waste through pyrolysis

- Addressing plastic pollution challenges

- Supporting circular economy initiatives

The Indian government’s support through policies like the National Policy on Biofuels has created a favorable environment for pyrolysis oil development. Several states, including Gujarat and Maharashtra, have established dedicated pyrolysis facilities, setting benchmarks for sustainable waste management practices.

Indian companies are pioneering innovative approaches to pyrolysis technology:

- Development of small-scale processing units

- Integration of IoT for process optimization

- Creation of standardized quality control measures

The market growth is in line with India’s commitment to reduce crude oil imports, positioning pyrolysis oil as a strategic alternative fuel source while addressing waste management challenges.

Japan's Growing Pyrolysis Oil Market and Future Outlook

Japan’s pyrolysis oil market is shifting towards sustainable waste management solutions. The country’s commitment to reducing plastic waste has led to significant investments in pyrolysis technology, with major corporations like Mitsubishi Chemical and JGC Holdings at the forefront of innovation.

Key Market Characteristics in Japan

- Advanced Technology Integration: Japanese firms prioritize automated systems and AI-driven processes in pyrolysis facilities

- Quality Control Standards: Strict regulations ensure high-grade pyrolysis oil production

- Municipal Support: Local governments provide incentives for waste-to-energy projects

The market is growing every year, driven by:

- Increasing demand for alternative chemical feedstock

- Adoption of circular economy practices

- Strict environmental regulations

Japanese companies have developed proprietary technologies that enhance pyrolysis oil quality:

Recent developments highlight Japan’s innovative efforts:

- Construction of integrated pyrolysis facilities in industrial areas

- Collaborations with Southeast Asian countries for technology transfer

- Research projects focused on optimizing catalysts

The market value is expected to reach the target by 2025, consolidating Japan’s leading position in waste-to-energy technology.

The Future of Pyrolysis Oil: What's on the Horizon?

Innovative advancements in pyrolysis technology have the potential to transform the industry. New catalytic process is making a major breakthrough, which is expected to increase oil production. These advancements could make pyrolysis oil production more commercially feasible at various scales.

Key Technological Breakthroughs

- Microwave-assisted pyrolysis systems

- AI-powered process optimization

- Hybrid reactor designs

- Advanced separation techniques

Research institutions are working on intelligent reactor systems that use machine learning algorithms to optimize production parameters in real-time. These systems have the capability to adjust temperature, pressure, and residence time in order to maximize yield quality, potentially reducing waste by 30%.

The combination of IoT sensors and blockchain technology is expected to improve transparency in the supply chain and control over product quality. This digital transformation has the potential to establish standardized quality metrics throughout the industry by 2033.

Market Predictions 2025-2033

- Increased production efficiency,

- Reduced costs,

- Market penetration in emerging sectors such as transportation and pharmaceuticals

- Increased investment in research and development

Emerging research is focusing on optimizing bio-based feedstocks and developing catalysts. Scientists are investigating new materials such as metal-organic frameworks (MOFs) that could revolutionize the conversion process, potentially achieving high conversion rates.

The creation of modular pyrolysis units opens up opportunities for decentralized production. These units could enable local waste-to-energy solutions, which would be especially beneficial for remote communities and developing regions.

Collaborative research initiatives between industry leaders and academic institutions are speeding up innovation cycles. Current projects are exploring the integration of carbon capture and co-production of hydrogen, positioning pyrolysis oil as a key player in the transition to a hydrogen economy.

Competitive Overview: Key Players in the Pyrolysis Oil Market

The pyrolysis oil market has several key players who are influencing the industry through strategic actions and technological advancements.

Key Market Leaders

- Bioenergy AE Côte-Nord— Canada

- Kerry Group— Ireland

- Pyrocell— Sweden

- TWENCE— Netherlands

- Green Fuel Nordic— Finland

- Ensyn— Canada

- Agilyx Corporation— United States

- Plastic Energy— United Kingdom

- BTG Bioliquids— Netherlands

- Covanta Holding Corporation— United States

Overall

| Report Metric | Details |

|---|---|

| Report Name | Pyrolysis Oil Market Report |

| Base Year | 2024 |

| Segment by Type |

· Bio-Oil · Synthetic Oil |

| Segment by Application |

· Power Generation · Transportation Fuel · Chemical Industry · Industrial Heating |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The pyrolysis oil market is at a crucial stage in its development, ready to transform the global energy scene.The market size is expected to gradually expand in the next few years, which shows that the industry has great potential and the market acceptance is constantly improving.

The way forward indicates a need for increased investment in research and development (R&D), stronger international partnerships, and improved production capabilities. As sustainability becomes a global necessity, pyrolysis oil’s position as a viable fossil fuel substitute continues to grow, supported by government initiatives and rising industrial demand.

The market’s trajectory suggests a future where pyrolysis oil plays a central role in the global transition toward renewable energy sources, supporting both environmental preservation and economic growth.

Global Pyrolysis Oil Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Pyrolysis Oil Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Pyrolysis Oil MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Pyrolysis OilPlayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Pyrolysis Oil Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Pyrolysis Oil Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Pyrolysis Oil Consumer Insights

- Demographics and Buying Behaviors

- TargetAudience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Pyrolysis Oil MarketInsights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the pyrolysis oil market from 2025 to 2030?

The pyrolysis oil market is projected to grow from $622.3 million in 2025 to $2624.48 Million by 2030, highlighting its increasing importance as a renewable energy source.

What are the upstream and downstream factors affecting the pyrolysis oil market?

Upstream factors include raw materials sourcing which impacts production processes, while downstream forces encompass distribution channels and application sectors where pyrolysis oil is used, both of which shape market dynamics significantly.

What trends are currently shaping the future of the pyrolysis oil market?

Key trends driving the growth of the pyrolysis oil market include sustainability initiatives, technological advancements in pyrolysis processes, and government regulations promoting cleaner renewable energy sources.

What challenges does the pyrolysis oil industry face?

The pyrolysis oil industry faces several challenges including production complexities, technical difficulties in manufacturing processes, regulatory barriers to market entry, and strategies must be developed to overcome these obstacles.

How do geopolitical factors influence pyrolysis oil production?

Geopolitical tensions can affect energy policies and subsequently impact the production and trade of pyrolysis oil. Countries are strategizing to enhance energy independence by utilizing pyrolysis oil as an alternative fuel source.

What applications are driving demand for pyrolysis oil?

Demand for pyrolysis oil is fueled by its various applications such as an alternative fuel source for power generation, heating processes, and its use as a chemical feedstock in different industrial sectors.