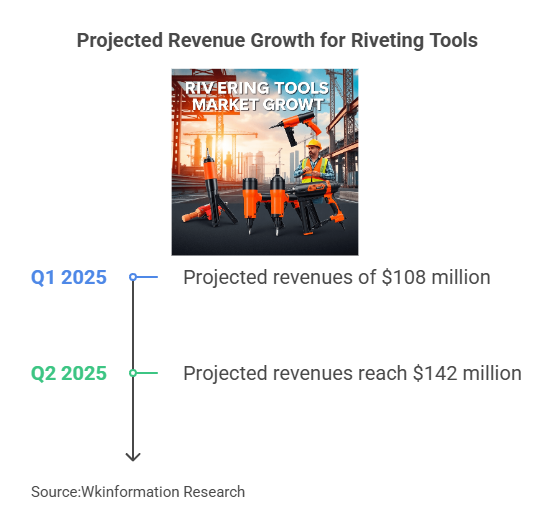

Quarterly Outlook: Riveting Tools Q1 and Q2 2025

Based on the overall 2025 market size of approximately $530 million and an expected CAGR of 6.6% by 2030, Wkinformation Research forecasts an uneven yet dynamic performance for Riveting Tools in the early part of the year.

Our detailed analysis indicates that Q1 could realize revenues in the vicinity of $108 million as market momentum begins to build, while Q2 is poised for a sharper upswing—projected to reach roughly $142 million—driven by accelerated industrial activity and a rebound in supply chain efficiencies. This uneven quarterly progression not only reflects seasonal variances and operational realities but also underscores the strategic importance of key regions such as India, the USA, and China, where robust infrastructure investments and a thriving manufacturing base continue to propel market growth.

Key Trends Influencing the Riveting Tools Market

Technological Advancements

The riveting tools market is witnessing a significant shift towards advanced technologies. One of the most notable changes is the growing preference for battery-powered tools. These tools are increasingly favored due to their efficiency and ease of handling, particularly in transportation applications such as vehicle body and flooring installations. The rise of battery-powered riveting tools has led to a decline in demand for traditional pneumatic tools, highlighting a broader trend towards more versatile and user-friendly solutions in the industry.

Regional Insights

Asia (China and India)

The Asia Pacific region, spearheaded by China and India, plays a pivotal role in the global riveting tools market. This dominance can be attributed to the surging demands for maintenance, repair, and operations (MRO), alongside assembly operations within these countries. As manufacturing hubs, both nations are experiencing rapid infrastructural development which propels market growth further.

USA

The United States also remains a significant player in the riveting tools market. However, its growth rate is expected to trail behind that of Asia. The slower pace can be linked to mature infrastructure projects and a more saturated market environment. Despite this, ongoing technological advancements continue to support steady progress.

Application Areas

Riveting tools are integral across various sectors, showcasing their versatility and importance:

- Automotive Industry: This sector stands out with riveting tools being crucial for enhancing production rates of passenger cars and commercial vehicles. With an anticipated revenue-based CAGR of 4.8%, the automotive industry exemplifies the potential for growth driven by increased vehicle manufacturing needs.

- Aerospace & Construction: Beyond automotive, riveting tools are extensively used in aerospace and construction sectors. Their application in assembling aircraft components and building steel structures underscores their indispensability in ensuring structural integrity and longevity.

These trends collectively shape the future trajectory of the riveting tools market, underscoring pivotal shifts in technology adoption, regional dynamics, and sectoral applications.

Market Segmentation Analysis

Product Categories

The riveting tools market is a diverse landscape, segmented into several key product categories. Each category plays a unique role in fulfilling industry-specific needs:

- Pneumatic Tools: Known for their speed and efficiency, pneumatic riveting tools are a staple in sectors requiring rapid assembly and minimal maintenance. They are favored in high-volume production environments due to their durability and cost-effectiveness.

- Hydro-Pneumatic Tools: These tools blend the benefits of hydraulic and pneumatic technologies, offering enhanced power and precision. Commonly used in heavy-duty applications such as aerospace and automotive manufacturing, hydro-pneumatic tools provide superior performance where strength is paramount.

- Handheld Lever Tools: Ideal for small-scale operations or fieldwork, these tools offer portability and simplicity. Handheld lever tools are often employed in maintenance, repair, and operations (MRO) across various industries.

Growth Drivers by Segment

Different segments within the riveting tools market experience growth due to specific industry demands:

- Pneumatic Tools: Their popularity stems from high-speed performance coupled with low operational costs. Industries like automotive and general manufacturing favor pneumatic options for large-scale production lines.

- Hydro-Pneumatic Tools: The need for precision and power drives demand in sectors such as aerospace, where component integrity is critical. These tools’ ability to handle complex tasks ensures their continued growth within specialized applications.

- Handheld Lever Tools: The rise of on-site maintenance and repair tasks fuels the demand for portable solutions. Industries focusing on mobility and adaptability find handheld lever tools indispensable.

The 2025 riveting tools market explosion highlights the pivotal role of India, USA, and China. These countries drive 80% of global growth by leveraging diverse product categories tailored to meet regional industrial demands. This segmentation not only reveals the dynamic nature of the market but also underscores the importance of aligning product offerings with industry-specific requirements.

Country-Specific Analysis

India’s Role in Market Growth

India is expected to play a crucial role in the significant growth of the riveting tools market projected for 2025. The country’s strong manufacturing industry, supported by initiatives like Make in India, greatly increases the demand for advanced riveting solutions. Furthermore, rising investments in infrastructure and construction projects further drive the need for efficient and durable tools, solidifying India’s position as an important player.

Key Factors Driving India’s Contribution

- Manufacturing Sector: A rapidly growing automotive industry demands high-quality riveting tools for vehicle assembly and maintenance.

- Construction Boom: Urbanization and government-backed infrastructure projects necessitate extensive use of riveting tools.

USA’s Positioning

The USA remains a key player in the global riveting tools market, despite facing challenges from faster-growing regions like Asia. The country’s focus on technological innovation and advanced manufacturing processes ensures its continued importance.

Factors Influencing USA’s Market Presence

- Advanced Technologies: Adoption of battery-powered and automated riveting systems is prevalent, catering to sectors such as aerospace and automotive.

- Market Challenges: Competition from Asian markets, particularly China and India, poses growth challenges due to cost advantages and rapid industrialization.

China’s Dominance

China is expected to be a major driving force behind the growth of the riveting tools market in 2025. With its large industrial base and aggressive infrastructure developments, China leads in both production and consumption of riveting tools.

Key Elements Contributing to China’s Dominance

- Industrial Base: Massive manufacturing capabilities support large-scale production of various tool types.

- Infrastructure Investments: Government-driven projects enhance demand across construction and transportation sectors.

Moreover, China’s focus on robotic automation, as highlighted in a recent report, is set to revolutionize its manufacturing sector further, optimizing production processes and increasing output efficiency.

This analysis highlights the significant roles that India, USA, and China play in shaping the future of the global riveting tools market. Each country’s unique strengths contribute to the dynamic growth trajectory anticipated through 2025.

Competitive Landscape

The global riveting tools market is driven by key players that specialize in advanced fastening solutions across various industries. Stanley Engineered Fastening, Cherry Aerospace, and GESIPA Blindniettechnik GmbH are recognized for their high-performance riveting systems, catering to aerospace, automotive, and industrial applications. Arconic Fastening Systems and Howmet Aerospace (Marson) provide precision fastening solutions tailored for structural integrity and durability. Companies like Rivtec, Sioux Tools, Inc., and AVK Industrial Products focus on innovative hand and power-driven riveting tools to enhance efficiency and productivity. Meanwhile, Ingersoll Rand and Ace Rivet & Fastener Inc. contribute to the market with robust and versatile riveting solutions designed for diverse industrial requirements.

Major Market Players

In the riveting tools industry, several key manufacturers dominate the landscape. Notable companies include:

- GESIPA Blindniettechnik GmbH: Known for its innovation in blind riveting technology, GESIPA offers a wide range of tools designed for various industrial applications.

- Arconic Inc.: With a strong focus on aerospace and automotive sectors, Arconic provides advanced fastening systems designed to meet demanding specifications.

- Stanley Black & Decker Inc.: A global leader in tool manufacturing, this company combines traditional craftsmanship with modern technological advancements to deliver high-performance riveting solutions.

Strategies for Growth

To maintain a competitive advantage, these market leaders employ several growth strategies:

- Innovation and R&D Investment: Continuous investment in research and development enables companies to introduce cutting-edge products such as battery-powered tools that cater to evolving consumer needs.

- Mergers and Acquisitions: By acquiring smaller firms or forming strategic alliances, major players expand their market reach and enhance their product portfolios.

- Market Expansion: Targeting emerging markets in Asia and increasing presence in established regions like North America are crucial strategies for tapping into new customer bases.

- Customer-Centric Solutions: Developing customized solutions tailored to specific industry requirements helps manufacturers build lasting relationships with clients across diverse sectors.

By Application:

Automotive and Aerospace: Riveting tools are essential in the automotive and aerospace industries for assembling components, ensuring structural integrity, and meeting stringent safety standards.

Building and Construction: In the construction sector, riveting tools are used for joining metal structures, contributing to the durability and stability of buildings and infrastructure projects.

Transportation: Riveting tools play a crucial role in the manufacturing and maintenance of transportation vehicles, including trains and ships, where strong and reliable joints are necessary.

Woodworking and Decorative: In woodworking, riveting tools are used for decorative applications and in the assembly of furniture and cabinetry, providing both functionality and aesthetic appeal.

Others: This category includes various other applications where riveting tools are utilized, such as in the production of machinery and equipment across different industries.

Conclusion

The riveting tools market is expected to undergo a major change by 2025, with India, the USA, and China leading 80% of its global growth. This expansion is driven by strong demands in construction, automotive, and manufacturing industries. The shift towards advanced technologies like battery-powered tools shows an industry-wide evolution. As key players continue to innovate and adapt, the future outlook looks promising. Keeping an eye on these global industry trends shows a market full of opportunities, preparing for what can be called the 2025 Riveting Tools Market Explosion.

Frequently Asked Questions (FAQ)

What are the key growth drivers in the riveting tools market?

The market is primarily driven by technological advancements, increasing demand in construction and automotive industries, and growing manufacturing activities across regions.

Which countries are leading the market growth?

India, USA, and China are the dominant players, collectively accounting for 80% of the global market growth by 2025.

What are the major trends shaping the industry?

Key trends include the adoption of battery-powered tools, technological innovations, and the development of customer-specific solutions.

How are manufacturers expanding their market presence?

Companies are focusing on emerging Asian markets while strengthening their position in established regions like North America.

What strategies are companies using for growth?

Major strategies include product innovation, portfolio expansion, targeting emerging markets, and developing customized solutions for specific industries.

What is the market outlook for 2025?

The market is expected to experience significant growth, termed as the “2025 Riveting Tools Market Explosion,” driven by industrial demands and technological evolution.

Which sectors show the highest demand for riveting tools?

Construction, automotive, and manufacturing industries demonstrate the strongest demand for riveting tools.

How are companies adapting to market changes?

Companies are investing in R&D, enhancing product portfolios, and developing customer-centric solutions to meet evolving market demands.