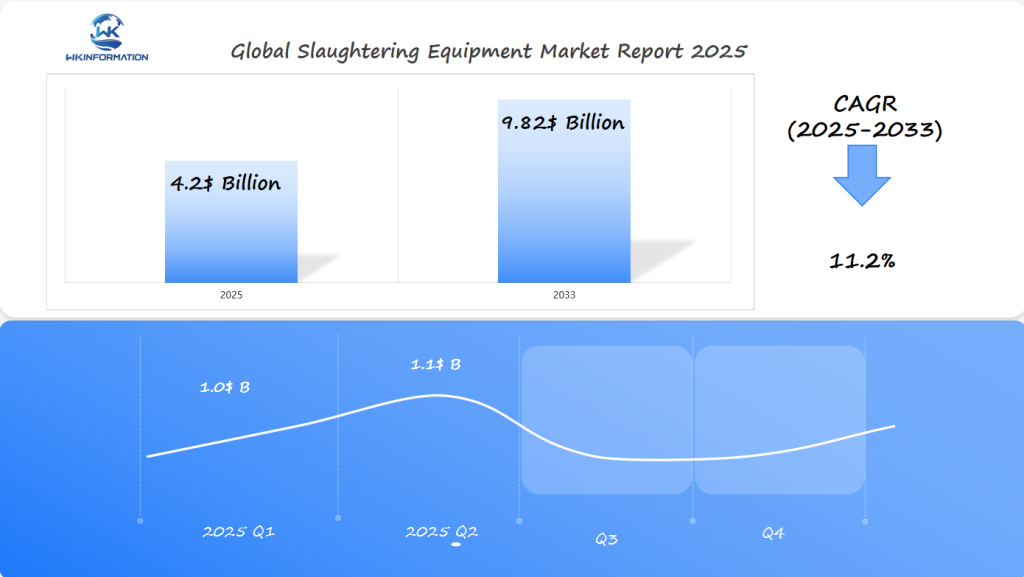

2025 Slaughtering Equipment Market Growth: Reaching $4.2 Billion with Efficient Meat Processing in Germany, France, and the Netherlands

Explore how Trump’s trade policies impact the European slaughtering equipment market, focusing on Germany, France, and the Netherlands. Discover market trends, technological innovations, and regulatory influences shaping this vital industry. Learn about growth projections, challenges, and opportunities in meat processing equipment.

- Last Updated:

Slaughtering Equipment Market: Q1 and Q2 2025 Predictions

The Slaughtering Equipment market, valued at approximately USD 4.2 billion in 2025, will experience growth driven by advancements in automation and efficiency in meat processing industries.

In Q1 2025, the market is expected to generate around USD 1.0 billion, with Germany, France, and the Netherlands contributing significantly to this demand. By Q2 2025, the market is projected to increase to approximately USD 1.1 billion as meat processing plants continue to invest in more efficient and automated systems to meet the rising demand for meat products while reducing labor costs and improving safety standards.

Understanding the Slaughtering Equipment Market: Supply Chain Dynamics

To understand the current trends in the slaughtering equipment market, it’s important to look at the supply chain dynamics. There are two key factors at play here: upstream factors and downstream implications.

Upstream Factors

Upstream factors have a significant impact on equipment demand. These factors include:

- Availability of raw materials

- Manufacturing capabilities

The production of slaughtering equipment heavily relies on materials such as stainless steel and electronic components. If there are fluctuations in the availability of these resources, it can directly affect manufacturing timelines and costs. Additionally, advancements in manufacturing processes like precision engineering and automation can improve production efficiency and the quality of equipment.

Downstream Implications

Downstream implications are equally important for meat producers and processors. As consumer preferences shift towards processed meat products, the demand for sophisticated slaughtering equipment increases. This demand requires advanced machinery that improves operational efficiency while maintaining high safety standards.

Here are some specific requirements for meat producers and processors:

- Meat producers need equipment that not only meets their production volume needs but also integrates smoothly into their existing processing lines.

- Processors prioritize operational efficiency, which includes minimizing downtime and ensuring consistent product quality.

These requirements highlight the importance of choosing reliable and adaptable slaughtering solutions to meet changing market demands.

The Dynamic Market Environment

The interaction between upstream supply constraints and downstream operational needs creates a dynamic market environment. Companies in this industry must navigate these complexities to stay competitive. This means they need to focus on both innovating equipment design and managing their supply chain strategically.

By doing so, these companies can effectively meet the growing demands of the industry while also following strict safety and quality standards.

Key Trends Shaping the Slaughtering Equipment Industry

Technological Advancements are leading the way in the slaughtering equipment industry, greatly impacting its development. One of the key trends is the integration of automation and robotics into slaughtering processes. These technologies are not just improving efficiency; they are completely transforming productivity by streamlining operations, reducing labor costs, and increasing precision in meat processing tasks.

1. Automation Technologies

These include robotic arms for cutting and deboning, automated conveyors for efficient movement of carcasses, and advanced sensors for quality control. These technologies minimize human error and ensure consistent product quality.

2. Innovations Driving Automation

Recent innovations such as machine vision systems allow equipment to make precise cuts based on real-time data analysis. This capability not only improves yield but also reduces waste—a critical factor in cost management for meat processors.

The adoption of these automation technologies contributes to substantial efficiency improvements throughout the slaughtering process. By using robotics, companies can achieve higher throughput rates without compromising on safety or quality standards. This technological leap is particularly beneficial in countries like Germany, France, and the Netherlands where high production demand necessitates cutting-edge solutions.

In addition to enhancing operational efficiency, automation in slaughtering equipment also supports compliance with stringent food safety regulations. Automated systems can be programmed to adhere strictly to hygiene protocols, thus preventing contamination risks and ensuring that meat products meet international safety standards.

The rapid pace of technological advancements in this sector is not only shaping the market landscape but also creating new opportunities for innovation and growth among equipment manufacturers. As automation technologies continue to evolve, they will play an increasingly vital role in addressing both current challenges and future demands within the global meat processing industry.

Overcoming Challenges in the Slaughtering Equipment Sector

Navigating the slaughtering equipment market comes with a unique set of challenges for manufacturers and processors. One major obstacle is the need to comply with stringent regulatory requirements. In Europe, regulations around meat processing are rigorous, focusing on ensuring food safety and animal welfare. This necessitates a high level of diligence from equipment manufacturers to ensure their products meet these standards.

Industry Challenges

1. Regulatory Compliance

The European Union enforces strict guidelines on meat processing operations, which means that slaughtering equipment must be designed to adhere to these protocols. For instance, regulations require specific hygiene controls and traceability systems within the slaughterhouse environment. This adds complexity to the manufacturing process but is essential for maintaining market access across Europe.

2. Cost Management

The development and production of sophisticated slaughtering technology can be expensive. Companies must balance the costs of innovation with competitive pricing strategies. This involves not only manufacturing costs but also expenses related to compliance testing and certification.

Adhering to safety and quality standards is paramount in overcoming these challenges. Advanced equipment solutions are being developed that integrate innovative technologies such as automation and robotics. These innovations help streamline operations, reduce human error, and maintain consistent product quality.

The application of cutting-edge technology ensures that machinery not only complies with existing regulations but also anticipates future changes within the regulatory landscape. By investing in technology that enhances operational efficiency while ensuring compliance, companies can better manage costs and improve their market position.

Leading firms are setting benchmarks by developing equipment that exceeds current standards, leveraging automation for precision and reliability. This proactive approach helps them stay ahead in a highly competitive market where regulatory compliance is non-negotiable.

The ability to effectively navigate these industry challenges will define success for companies operating in this sector, emphasizing the importance of continual innovation in slaughtering equipment solutions.

Geopolitical Impact on Slaughtering Equipment Manufacturing and Distribution

The European slaughtering equipment market is heavily influenced by geopolitical factors and evolving trade policies. Trade agreements within Europe significantly affect the distribution of slaughtering equipment, impacting key players such as Germany, France, and the Netherlands.

Influence of Trade Agreements

The European Union’s trade policies facilitate the seamless movement of goods across member states. For countries like Germany, France, and the Netherlands, these agreements are crucial in maintaining a steady flow of slaughtering equipment. The EU’s common market allows these nations to leverage their advanced manufacturing capabilities, ensuring that equipment can be distributed efficiently throughout Europe. This framework supports not only local demand but also strengthens export potential by reducing tariffs and streamlining regulatory compliance.

Geopolitical Tensions

Despite the benefits of trade agreements, geopolitical tensions pose significant challenges. Rising protectionism and shifts in political landscapes can disrupt supply chains. For instance, Brexit has introduced uncertainties around trade tariffs and border regulations between the UK and EU countries. Such changes necessitate strategic adjustments by manufacturers to maintain market access and manage costs effectively.

This intricate balance between cooperative trade policies and geopolitical uncertainties plays a pivotal role in shaping the operational strategies of slaughtering equipment manufacturers. The ability to navigate these external factors is essential for sustaining growth in this competitive market landscape.

Market Segmentation: Types of Slaughtering Equipment and Their Applications

The slaughtering equipment market is diverse, with a range of specialized tools designed to meet the needs of the meat processing industry. Understanding the different equipment types and their specific applications is crucial for stakeholders looking to optimize operations.

Key Types of Slaughtering Equipment

- Stunning Devices

- Stunning devices play a critical role in ensuring humane animal treatment before slaughter. These devices are engineered to render animals unconscious quickly, reducing stress and improving meat quality. Common types include electric, pneumatic, and captive bolt stunners.

- Processing Machinery

- Processing machinery encompasses a wide array of equipment used downstream in the slaughtering process:

- Slicers and Portioning Machines: Essential for precision cutting and portion control, these machines are driven by technological advancements that enhance speed and accuracy.

- Deboning Tools: Automated deboning equipment improves efficiency by reducing manual labor while ensuring consistent quality.

- Grinders and Mixers: Used for processing ground meats and mixes, these machines are vital for producing sausages and other processed meat products.

Applications and Trends

- Stunning Devices: Increasingly utilized in facilities prioritizing humane practices, these devices align with evolving regulatory standards focused on animal welfare.

- Slicers and Portioning Machines: The rise in consumer demand for portion-controlled packaged meats has fueled advancements in slicing technology, leading to more precise equipment offerings.

- Deboning Tools: As labor shortages continue to challenge the industry, automated deboning solutions are becoming essential for maintaining productivity levels.

- Grinders and Mixers: With the growing preference for processed foods, companies are investing in advanced grinders that ensure consistency in texture and flavor across large production volumes.

These varied applications highlight the segmentation within the market, where each category addresses specific operational needs while driving innovation. The ability to adapt to these trends is crucial for manufacturers aiming to capture market share in a competitive landscape.

The Importance of Slaughtering Equipment in Maintaining Meat Quality and Safety Standards

Advanced slaughtering technology is crucial for improving processing efficiency and ensuring meat quality. As the market for slaughtering equipment grows, it becomes increasingly important to maintain strict quality control measures throughout production.

Slaughtering equipment is essential for ensuring that meat products meet safety standards. By using automation and robotics, these systems reduce human error, minimize contamination risks, and improve the handling of meat products. As a result, both safety and quality outcomes are significantly enhanced.

How Slaughtering Equipment Contributes to Meat Quality and Safety

- Precision and Consistency: Advanced equipment allows for precise control over critical parameters such as temperature, pressure, and timing. This precision ensures that each cut of meat is processed consistently, meeting specific quality standards.

- Hygienic Design: Modern slaughtering machines are designed with hygiene as a priority. Features like easy-to-clean surfaces and stainless-steel components help to prevent bacterial growth, ensuring that sanitary conditions are maintained throughout the production cycle.

- Real-Time Monitoring: The integration of digital monitoring tools enables real-time tracking of key quality indicators. This capability allows processors to quickly identify and rectify any deviations from standard operating procedures, thereby maintaining high-quality output.

- Regulatory Compliance: Adherence to international food safety standards is crucial for market access. Advanced slaughtering technology supports compliance with these regulations by providing reliable documentation and traceability of processes.

The development and adoption of innovative slaughtering equipment are essential for meeting consumer expectations for safe, high-quality meat products while also supporting efficient production practices. As the industry advances, these technologies will continue to play a pivotal role in shaping the future landscape of meat processing standards.

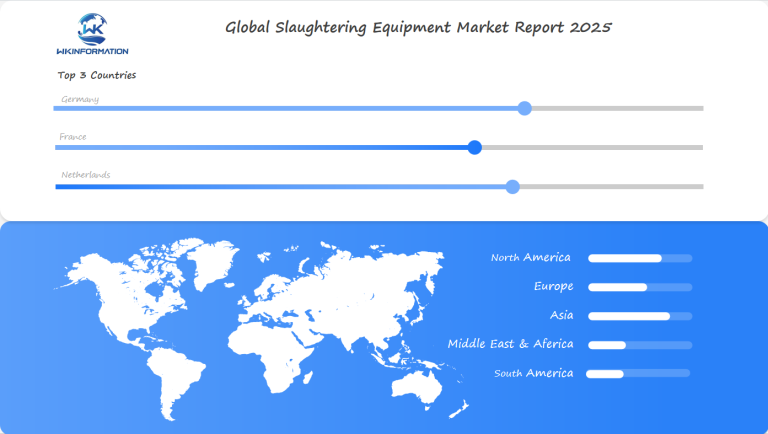

Regional Insights: Slaughtering Equipment Market Growth in Germany, France, and the Netherlands

Regional Analysis of the slaughtering equipment market highlights the significance of Germany, France, and the Netherlands as pivotal players in Europe. These countries are not only driving technological advancements but also responding to evolving consumption patterns and production capabilities.

Germany

- Consumption Patterns: Germany’s meat consumption remains robust, with a strong preference for pork and poultry. This demand fuels the need for advanced slaughtering equipment capable of handling high volumes efficiently.

- Production Capabilities: As a leader in manufacturing technology, Germany continually invests in cutting-edge meat processing facilities. This investment ensures that domestic producers can meet both local demand and export requirements with precision and efficiency.

France

- Consumption Patterns: French consumers exhibit a growing inclination towards quality-assured meat products. The emphasis on stringent quality standards increases the demand for sophisticated slaughtering technologies that guarantee product integrity.

- Production Capabilities: France’s strategic focus on enhancing its meat export industry necessitates state-of-the-art equipment. The integration of automation within slaughterhouses is pivotal to maintaining competitiveness in both European and global markets.

The Netherlands

- Consumption Patterns: The Netherlands boasts a dynamic meat market characterized by innovative consumer products. This diversity drives demand for versatile slaughtering solutions that can cater to varied processing needs.

- Production Capabilities: Known for its agricultural innovation, the Netherlands invests heavily in sustainable and efficient meat processing technologies. Advanced equipment solutions are central to supporting the country’s ambition as a leading exporter.

Each country’s unique market dynamics contribute significantly to the overall growth trajectory of the slaughtering equipment industry within Europe. These regional insights underscore the importance of adapting equipment solutions to local needs while maintaining an eye on global market trends.

Germany’s Leading Role in Slaughtering Equipment Technology

Germany is a leader in slaughtering equipment technology, thanks to its strong engineering industry and tradition of innovation. The country is known for its precise engineering and has built a reputation for creating advanced machines that improve efficiency and quality in meat processing.

1. Technological Innovations

German companies are leading the way in automation and robotics advancements. These innovations not only make the slaughtering process more efficient but also ensure higher safety standards, reducing human error in meat production.

2. Industry Leaders

Companies like GEA Group and Marel play a crucial role in this industry. They are recognized for their contribution to developing highly efficient slicing and portioning machines that serve both local and international markets.

3. Research and Development (R&D)

Germany’s dedication to research and development is a key factor in maintaining its leadership position. Investments in advanced technologies have resulted in equipment that meets strict European safety and quality standards, appealing to global markets seeking dependable solutions.

4. Export Capabilities

The country’s strong export framework supports the distribution of German-made slaughtering equipment across Europe and beyond. This capability reflects not only Germany’s technological expertise but also its strategic market positioning.

The combination of technological innovation and strategic market factors solidifies Germany’s leadership role in slaughtering equipment technology, setting industry standards worldwide.

France’s Demand for Slaughtering Equipment in the Meat Export Industry

France is a major player in the European meat export industry, creating a strong need for advanced slaughtering equipment. Several factors are driving this demand:

1. Export-Oriented Market

French producers have a strong focus on exporting high-quality meat products, which requires them to use cutting-edge equipment that ensures efficiency and meets international standards. This equipment is crucial for maintaining France’s reputation as a producer of premium meat products.

2. Quality and Safety Standards

Global markets are imposing strict quality and safety standards, leading French meat exporters to invest more in innovative slaughtering technology. This investment is necessary to ensure that their products meet the demanding requirements of foreign markets.

3. Technological Integration

Slaughterhouses are integrating automated systems to increase productivity and maintain consistent product quality. Technologies like robotics and AI-driven monitoring systems are becoming essential in French facilities to streamline operations and reduce human error.

4. Sustainability Concerns

Environmental considerations are influencing the industry’s choice of equipment. French meat processors who want to minimize their environmental impact are increasingly adopting sustainable practices such as energy-efficient machinery and waste reduction technologies.

These increased investments demonstrate France’s commitment to staying competitive in the global meat market. The industry’s focus on sophisticated equipment shows its willingness to adapt to changing demands while striving for excellence in both quality and sustainability.

Netherlands’s Contribution to Advanced Slaughtering Equipment Solutions

The Netherlands has become a major player in developing advanced slaughtering equipment, demonstrating its strong commitment to improving efficiency and sustainability in the meat processing industry. Using its rich agricultural history and innovative technological abilities, the country is crucial in shaping modern slaughtering methods.

1. Technological Innovation

Dutch companies are leading the way in incorporating cutting-edge technologies, such as AI-driven systems and IoT solutions, into slaughtering equipment. This integration not only boosts operational efficiency but also ensures adherence to stringent quality standards.

2. Focus on Sustainability

Environmental considerations are central to the Dutch approach. By investing in eco-friendly machinery that minimizes waste and reduces energy consumption, the Netherlands sets a benchmark for sustainable meat processing solutions worldwide.

3. Research and Development

With numerous research institutions dedicated to food technology, the Netherlands fosters an environment conducive to innovation. Collaborative efforts between academia and industry result in continuous advancements in equipment design and functionality.

4. Global Influence

The impact of Dutch innovations is felt beyond its borders, with many countries adopting their advanced slaughtering technologies. This international reach underscores the Netherlands’ position as a leader in exporting not just products but also expertise in meat processing solutions.

These contributions highlight how the Netherlands is playing a vital role in advancing global slaughtering equipment through innovation and sustainable practices.

Innovations in Slaughtering Equipment for Automation and Efficiency

The meat processing industry is rapidly evolving with advancements in automation and efficiency-driven technologies. Modern slaughtering equipment now integrates robotic systems, AI-powered vision inspection, and automated stunning methods to enhance precision, speed, and hygiene. Smart conveyor and sorting systems equipped with IoT and RFID technology optimize workflow and minimize human intervention. Additionally, water and energy-efficient solutions, along with antimicrobial surface treatments, are improving sustainability and food safety. These innovations not only streamline operations but also ensure compliance with strict regulatory standards while meeting the growing global demand for high-quality meat products.

Key Competitors in the Slaughtering Equipment Market

The slaughtering equipment market is dominated by several major players who are crucial in shaping its landscape.

- Marel

- BAADER Group

- BAYLE SA

- Prime Equipment Group

- CTB

- Brower Equipment

- Jarvis Equipment

- Industries Riopel

- ASENA

- Dhopeshwar Engineering Private Limited

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Slaughtering Equipment Market Report |

| Base Year | 2024 |

| Segment by Type | ·Stunning Devices ·Processing Machinery ·Slicers and Portioning Machine ·Deboning Tools ·Grinders and Mixers ·Others |

| Segment by Application | ·Stunning Devices ·Slicers and Portioning Machines ·Deboning Tools ·Grinders and Mixers ·Others |

| Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The future outlook for the slaughtering equipment market in Europe remains promising, driven by continued advancements in technology and evolving consumer preferences. As automation and robotics become more deeply integrated into meat processing operations, stakeholders can anticipate significant improvements in efficiency and productivity.

- Technological Innovations: The ongoing development of advanced machinery will play a crucial role in meeting the growing demand for high-quality and safe meat products. This is especially pertinent as consumer expectations rise.

- Market Growth Potential: With projections indicating the market reaching $4.2 billion by 2025, there’s substantial opportunity for businesses to expand their footprint within Germany, France, and the Netherlands.

- Regulatory Compliance and Safety Standards: Companies that effectively navigate stringent regulatory landscapes while implementing innovative solutions will likely gain a competitive edge.

Stakeholders should focus on leveraging these technological advancements to optimize processes and meet both domestic and international demands. Embracing innovation while maintaining rigorous safety standards will be key to thriving in this dynamic sector. The path forward presents numerous opportunities for those willing to adapt and invest in cutting-edge solutions.

Global Slaughtering Equipment Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Slaughtering Equipment Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Slaughtering EquipmentMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Slaughtering Equipment players and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Slaughtering Equipment Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Slaughtering Equipment Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Slaughtering Equipment Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary of Slaughtering EquipmentMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the projected growth of the slaughtering equipment market by 2025?

The slaughtering equipment market is projected to grow to $4.2 billion by 2025, driven by increasing demand for efficient meat production in key European countries.

Which countries are considered key players in the European slaughtering equipment market?

Germany, France, and the Netherlands are identified as key players in the European slaughtering equipment market, significantly influencing market dynamics and consumption patterns.

How do technological advancements impact the slaughtering equipment industry?

Technological advancements, particularly in automation and robotics, are enhancing efficiency and productivity in slaughtering processes, contributing to overall improvements in operational efficiency within the meat processing industry.

What challenges do manufacturers face in the slaughtering equipment sector?

Manufacturers face several challenges including stringent regulatory compliance requirements and cost management issues, which necessitate innovative solutions to maintain safety and quality standards.

How do geopolitical factors affect the distribution of slaughtering equipment in Europe?

Geopolitical factors, including trade policies and tensions, significantly influence the distribution of slaughtering equipment across Europe, impacting supply chains and market access for manufacturers.

What types of slaughtering equipment are commonly used in the meat processing industry?

Common types of slaughtering equipment include stunning devices and processing machinery. Each type serves specific applications within the meat processing sector, with trends driving segmentation in product offerings.