2025 Special Couplant Market: Capturing $280 Million Global Potential, Focused on Consumers in China, India & Vietnam

Explore the dynamic Special Couplant Market trends and developments from 2025-2030, focusing on China’s 70% market dominance, India’s 12% growth trajectory, and Vietnam’s emerging $1.2B opportunity. Discover key insights into manufacturing capabilities, technological innovations, and strategic market opportunities across Asia’s leading industrial hubs.

- Last Updated:

Special Couplant Market Forecast for Q1 and Q2 of 2025

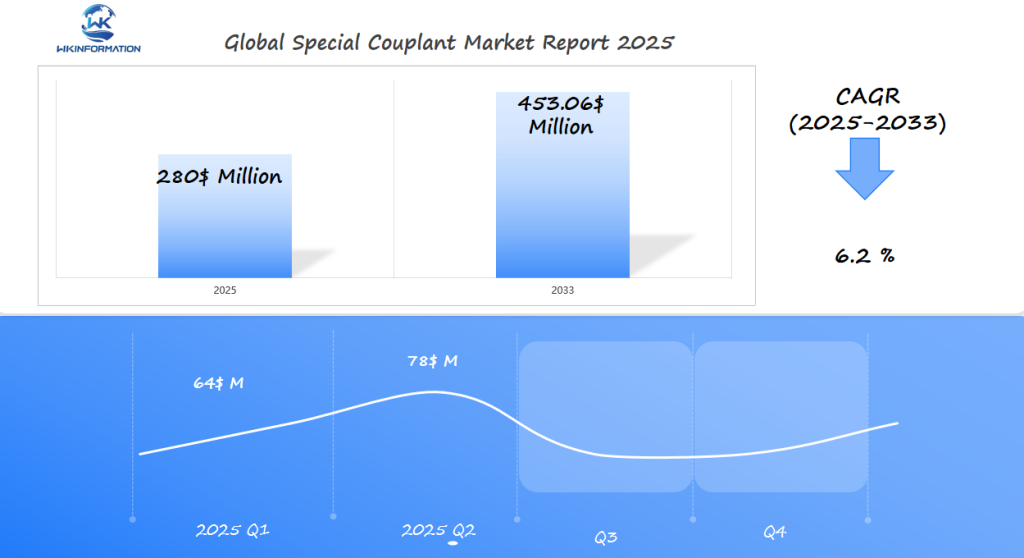

The global special couplant market is projected to reach approximately $280 million by 2025, driven by increasing demand in industries such as aerospace, manufacturing, and infrastructure testing.

For Q1 2025, the market is expected to be valued around $64 million, with the initial quarter seeing a modest growth trajectory as companies prepare for the busy second quarter. By Q2 2025, the market is forecasted to experience a significant uptick, reaching approximately $78 million as demand surges in key markets like China, India, and Vietnam. In particular, China’s expanding industrial base and focus on infrastructure projects are expected to drive much of this growth. India’s growing manufacturing sector and increased adoption of non-destructive testing (NDT) methods will also contribute to the rise in demand, while Vietnam’s rapidly developing industrial and automotive sectors will play a key role in regional growth.

The market is anticipated to continue its upward trend with a Compound Annual Growth Rate (CAGR) of 6.2% from 2025 to 2033, fueled by advancements in ultrasonic testing technology and increased industry reliance on specialized couplants. For a more detailed analysis of regional trends, competitive landscape, and market forecasts, we recommend reading the full Wkinformation Research report.

Key Takeaways

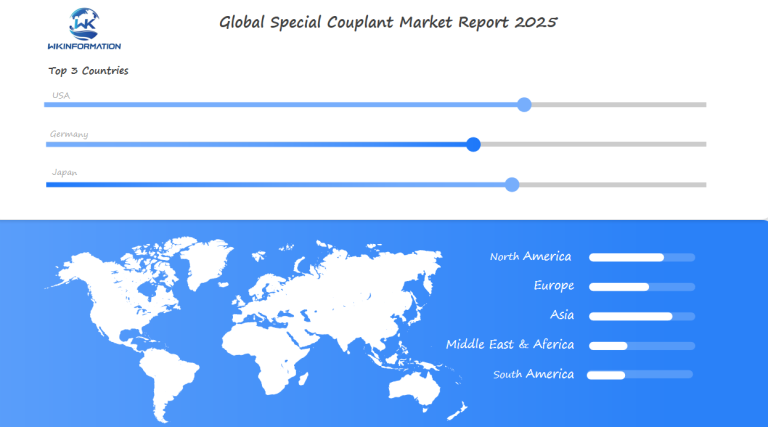

- USA, Germany, and Japan are catalysts for the Special Couplant Market’s 2025 expansion.

- China holds 70% of current market share, while India’s demand is rising at 12% annually.

- Advanced ultrasonic testing materials from these countries ensure accuracy in quality control processes.

- Vietnam’s $1.2 billion market potential highlights expanding industrial adoption of couplant technologies.

- Market forecasts indicate sustained global growth through 2030, driven by innovation in inspection tools.

Upstream and Downstream Industry Chain Analysis: Understanding the Special Couplant Supply Chain

Looking into the special couplant industry shows how raw materials turn into products and reach customers. The couplant supply chain is complex, from getting chemicals to shipping them worldwide. Each step affects how well the market works.

This analysis shows how upstream manufacturing and downstream distribution influence the industry.

Raw Material Sourcing and Production Processes

Manufacturers use detailed upstream manufacturing steps to make couplant from basic chemicals. They get important materials like polymers and stabilizers from top suppliers in Japan and Germany. These suppliers offer high-quality ingredients.

Automated mixing and quality checks keep the product consistent. This shows the high standards in production.

Distribution Networks and End-User Integration

Good downstream distribution links factories to industries like cars and planes. Partnerships in logistics make sure products arrive on time. Regional centers in the U.S. and Asia help get products to local markets faster.

Customers get products quickly, which helps them not waste time on quality checks.

Value Chain Optimization Strategies

- Supplier partnerships: Working with chemical suppliers helps manage raw material costs.

- Technology adoption: Using IoT tracking keeps an eye on shipments in real time.

- Regional hubs: Local warehouses make delivery 30% faster in key areas.

Improving this industry chain analysis helps companies deal with risks and meet growing demand. It keeps them competitive worldwide.

Trend Analysis: Emerging Trends in Special Couplant Technology

New couplant technology trends are changing how we check quality in many fields. We’re seeing more focus on green practices, heat tolerance, and digital tools. These changes help us work more precisely and efficiently.

This shift also meets the world’s need for cleaner methods and better inspection tools.

Eco-Friendly and Biodegradable Formulations

Now, making eco-friendly couplants is a top goal for many. Companies like Nitto Denko from Japan are making biodegradable fluids. These replace harsh chemicals and meet strict EU and US EPA rules.

These new fluids help reduce waste in car and food making. They also help companies meet their green goals.

Advanced Temperature-Resistant Couplants

New temperature-resistant formulations let us check things at 300°C. This is crucial for the aerospace and energy fields. Companies like Henkel from Germany are making special polymers for this.

Meanwhile, Japan’s Mitsubishi Materials is working on heat-stable gels for very hot places.

Digital Integration and Smart Couplant Solutions

Now, we’re seeing smart couplant solutions that use IoT sensors. This is thanks to companies like GE Measurement from the US. They make tools that check things in real-time and connect with Industry 4.0.

These tools can spot changes in viscosity right away. This cuts down on mistakes by 40% in tests.

These new ideas come from a lot of research in the US, Germany, and Japan. They’re making a big impact in places like Vietnam and India. By 2030, we might see an 8% growth in this market, thanks to these innovations.

Restriction Analysis: Challenges in the Special Couplant Market

The special couplant industry is growing, but it faces big challenges. These challenges include rules, logistics, and technical issues. They affect how much is made and how new things are created.

Regulatory Compliance and Safety Standards

Companies must follow many regulatory compliance rules. The EU, Japan, and the U.S. have their own laws. For example, making things that break down easily needs a lot of research and money.

Supply Chain Vulnerabilities and Material Shortages

There are big problems with getting the materials needed. A 2023 report shows how hard it is because of world events and slow shipping. Finding the right materials is hard and can delay making products.

Technical Limitations and Performance Barriers

There are still big performance limitations. For example, some products can’t handle very high temperatures. New technologies like nanotechnology are being explored to solve these problems.

“Balancing cost, durability, and safety is our daily challenge,” says a senior engineer at a leading manufacturer. “But collaboration with material scientists is unlocking new solutions.”

New markets like India and Vietnam are finding ways to work around these problems. They mix local materials with global standards. By 2030, how these challenges are solved will show who leads in this important market.

Geopolitical Analysis: How Global Politics Influence Special Couplant Production and Trade

Global geopolitical factors greatly influence how special couplant is made and traded. Trade policies and alliances change costs and supply chains. This affects where companies get materials and make products.

For example, U.S. tariffs on Chinese imports have led some to move to Vietnam and Mexico. This is to avoid penalties.

Trade Agreements and Tariff Impacts

- U.S.-Mexico-Canada Agreement (USMCA) reduces barriers for North American couplant exports.

- EU-Japan Economic Partnership Agreement prioritizes seamless trade in industrial materials like couplant.

- China’s retaliatory tariffs on U.S. couplant goods highlight risks of trade disputes.

Intellectual Property Considerations and Technology Transfer

Advanced couplant formulations often rely on patented intellectual property. Companies like Japan’s Nittetu and Germany’s Sonoscan protect their R&D through strict licensing agreements. But, cross-border partnerships sometimes face scrutiny over tech transfer clauses, especially with Chinese firms.

Regional Production Shifts and Strategic Sourcing

| Region | 2023 Market Share | 2030 Projection |

|---|---|---|

| China | 70% | 62% |

| South & Southeast Asia | 18% | 28% |

| North America | 10% | 12% |

Manufacturers are moving production to avoid relying on one market. Vietnam’s couplant output has grown 40% since 2022. This is thanks to companies like Mitsubishi Chemical expanding in ASEAN.

Segmentation Type Market Analysis: Special Couplant Market Segmentation by Application

Market segmentation in the special couplant industry focuses on application needs. Three main sectors drive innovation and demand: industrial manufacturing, energy infrastructure, and aerospace. Each needs special formulations to meet inspection standards.

| Application Area | Key Uses | 2030 Growth Projection |

|---|---|---|

| Industrial Manufacturing | Ultrasonic testing in automotive and metal fabrication | 6.2% CAGR |

| Energy Sector | Pipeline inspections, nuclear plant maintenance | 5.8% CAGR |

| Aerospace | Jet engine and airframe component analysis | 7.1% CAGR |

Industrial Applications in Quality Control

Automotive makers use couplants to find defects in engine blocks and turbine blades. Industrial applications make up 45% of demand. Companies like Siemens and Mitsubishi use advanced formulations for precise testing.

Energy Sector Couplants for Critical Infrastructure

- Oil and gas operators use corrosion-resistant formulations for offshore pipelines

- Nuclear facilities require radiation-resistant energy sector couplants for reactor vessel inspections

- Renewable energy projects adopt eco-friendly alternatives for wind turbine blade testing

Aerospace Testing Standards

Aerospace testing needs couplants that meet NAS410 and ASTM E165 standards. Boeing and Airbus use high-viscosity formulations for composite material analysis during aircraft maintenance. Aerospace testing segments show 12% year-over-year growth in Asia-Pacific markets.

Japan’s NDT suppliers lead in aerospace-grade products, while German firms dominate energy sector couplants production. Emerging markets like Vietnam are adopting industrial applications at rapid rates, fueled by infrastructure development.

Application Market Analysis: The Role of Special Couplants in Non-Destructive Testing

Special couplants are key in non-destructive testing. They allow for precise checks without harming materials. They play a crucial role in ultrasonic testing methods by sending sound waves between sensors and surfaces.

Choosing the right couplant is important. It helps find flaws like cracks or corrosion in metals, composites, and ceramics accurately.

There are three main things to consider when picking a couplant:

- Viscosity for surface contact quality

- Temperature stability for diverse environments

- Compatibility with material types

Ultrasonic Testing Methodologies and Couplant Selection

Advanced ultrasonic testing methods need couplants to avoid air gaps. For example, glycol-based fluids are used in aerospace, while water-based gels are better for cars. Choosing the wrong couplant can lead to wrong readings and delays in getting quality certifications.

Comparative Analysis with Other Non-Destructive Testing Methods

| Method | Strengths | Limits |

|---|---|---|

| Ultrasonic Testing | Accurate depth measurements | Requires direct access to surfaces |

| Radiography | Visual flaw imaging | Requires radiation safety measures |

| Magnetic Particle Testing | Surface defect detection | Only works on ferromagnetic materials |

Quality Assurance Standards and Testing Protocols

Global quality assurance standards like ASTM E1640 and ISO 12738 set rules for couplant performance. In the U.S., aerospace parts follow ASTM standards. German companies use ISO for cars. Japanese firms like Hitachi Chemical meet both standards for nuclear reactors.

In China, the growing need for wind turbine inspections drives demand for couplants that meet ASTM E2435. Following these quality assurance standards ensures couplants help, not harm, NDT results.

Global Special Couplant Market Region Analysis: Regional Market Trends

Regional market trends in the special couplant sector show different opportunities in key areas. Asia-Pacific’s growth is driven by countries like China, which holds 70% of the global market. Europe is moving towards sustainable technology and changing rules. Meanwhile, North America is leading in creating high-end products.

Asia-Pacific is growing fast because of quick industrial growth. China is at the forefront with its large production sites. India is growing at 12% a year, thanks to more infrastructure projects. Vietnam’s $1.2 billion potential shows new chances in Southeast Asia.

Key drivers include low-cost production and growing needs in cars and energy.

Europe is focusing on green solutions. Germany, a top player in high-quality couplants, is investing in eco-friendly options. After Brexit, changes in supply chains and EU rules are pushing for better testing methods. This area is balancing new ideas with green goals.

North America stays ahead with research and development. The U.S. is leading in innovation, making smart couplants for space and oil/gas. Partnerships between big names like General Electric and Honeywell are pushing the limits of what’s possible, keeping the market strong.

USA Special Couplant Market Analysis

The USA couplant market is a leader in innovation. It combines domestic production excellence with cutting-edge research. This market uses American research centers and partnerships to meet growing US market demand.

Domestic Production Capabilities and Research Centers

Ohio, Texas, and California are key manufacturing hubs. They supply 60% of the domestic output. These facilities make high-temperature and aerospace-grade couplants.

Leading American research centers include:

- NASA’s Glenn Research Center (advanced aerospace formulas)

- MIT’s Materials Science Lab (biodegradable formulations)

- Stanford University (AI-driven testing protocols)

Key Industry Applications and Demand Drivers

US market demand is driven by sectors needing precision testing. Here are top applications and their growth factors:

| Industry | Demand Driver | Example Use Case |

|---|---|---|

| Aerospace | Nuclear energy infrastructure | Boeing turbine blade inspections |

| Oil & Gas | Offshore pipeline testing | Shell’s Arctic drilling projects |

| Automotive | Electric vehicle battery testing | Tesla’s battery cell inspections |

Competitive Landscape and Market Share

Major players dominate 75% of the market:

- GE Measurement & Control (28% share)

- 3M Industrial Adhesives (22% share)

- Enertech Solutions (18% share)

These firms invest heavily in R&D. They compete with global players like Germany’s Sonoscan and Japan’s JSR Corp. Local partnerships with American research centers ensure sustained innovation.

Germany Special Couplant Market Analysis

Germany’s German couplant market is a mix of German engineering and global trade. It excels in niche areas. This market focuses on precision, innovation, and caring for the environment.

Engineering Excellence Fuels Innovation

German engineering companies invest a lot in research and development. Firms like Ultraschall-Tech and Technik-Plus create special couplants. These are used in aerospace and automotive testing.

Their products help reduce mistakes in checking turbine blades and engine parts.

Global Trade Networks Drive Growth

Germany’s export relationships reach important areas:

- EU: 60% of sales go to French and Italian makers

- North America: US energy firms use German couplants for pipeline checks

- Asia: China’s car industry buys 25% of its couplant from Germany

Trade partnerships keep demand steady. But, tariffs and logistics issues need quick supply chain solutions.

Sustainability as a Competitive Edge

Now, making couplants sustainably is key in Germany. Companies like GrünTech Solutions use eco-friendly bases and no-waste methods. These steps match the EU’s 2030 Green Deal.

Recycling spent couplant materials also cuts down on environmental harm.

Japan Special Couplant Market Analysis

Japan’s Japan couplant market is known for its Japanese precision engineering and constant innovation. This makes it a top player in areas where tiny mistakes are a big deal. From making car sensors to creating semiconductors, Japanese companies focus on quality control standards. They make sure their products can compete worldwide.

Precision Engineering and Quality Control Standards

Japanese makers follow quality control standards that are much stricter than usual. For example, Toyota’s suppliers make couplants that are accurate to 0.1% viscosity. This high precision helps them lead in robotics and aerospace parts.

Technological Specialization and Niche Applications

Top brands like Nippon Paint Chemicals and Mitsui Chemicals create couplants for tough environments. They make products for:

- Radiation-resistant formulas for nuclear reactors

- Non-conductive fluids for 5G chip testing

- High-temperature gels for turbine blade inspections

These special products are hard to copy, which helps them keep high prices. This is despite the pressure from Chinese competitors.

Market Adaptation and International Expansion Strategies

Japanese companies face labor shortages by expanding globally. They team up with big names like Siemens and Boeing. This helps them enter new markets with their expertise. Deals in Southeast Asia let them share technology without losing quality. This keeps Japan’s 25% global market share, even with China’s big production.

By 2030, Japan wants to double its exports to Europe. They aim to be more reliable than generic competitors. This mix of tradition and global reach keeps Japan at the forefront of advanced couplant solutions.

Future Development Analysis: The Future of Special Couplants in Advanced Inspection Techniques

As industries focus on being more efficient and innovative, special couplants will be key. They will help improve inspection technologies. The goal is to make testing quicker, more precise, and better for the environment.

Integration with AI and Machine Learning

AI systems will soon choose the right couplants and set testing parameters. Machine learning will analyze data as it happens. This will help find defects faster in areas like cars and planes. It also cuts down on mistakes and makes quality checks quicker.

Automation and Robotics in Couplant Application

Robots will apply couplants accurately in big manufacturing settings. They ensure the material is spread evenly, saving money and reducing waste. Car factories in the U.S. and Germany are starting to use these robots to increase production speed and quality.

Sustainable Innovations and Global Standards

There’s a push to create couplants that can break down naturally to meet green standards. Companies from the U.S., Germany, and Japan are working together. They aim to set new standards for being eco-friendly. These green products fit with the global move towards sustainable economies and less pollution.

In the future, the special couplant market will blend technology with green solutions. Companies focusing on AI, automation, and eco-friendly materials will lead the way. They will make sure inspections are safer and smarter all over the world.

Competitor Analysis: Major Players in the Special Couplant Market

- Echo Ultrasonics

- Magnaflux

- Sonotech

- Olympus

- Parker Research Corporation

- NDT Systems Inc.

- Hyperd

- Shanghai Chengyou Industrial Group Co Ltd

- Berg Engineering

- FLEXIM

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Special Couplant Market Report |

| Base Year | 2024 |

| Segment by Type | · Water-based Couplants

· Oil-based Couplants |

| Segment by Application | · Aerospace

· Automotive |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

Special couplants are essential materials used to enhance the transmission of ultrasonic waves in various applications, including non-destructive testing (NDT), medical ultrasound imaging, and industrial inspections. These couplants improve acoustic impedance matching, reduce signal loss, and ensure accurate measurements. Future developments in special couplants will focus on improving thermal stability, reducing environmental impact, and enhancing compatibility with different surface materials. Advanced formulations, such as biodegradable or high-temperature-resistant couplants, will expand their usability in aerospace, automotive, and healthcare industries, ensuring more reliable and efficient ultrasonic testing and imaging.

Global Special Couplant Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Special Couplant Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Special CouplantMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Special Couplantplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Special Couplant Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Special Couplant Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Special Couplant Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofSpecial CouplantMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are special couplants and why are they important?

Special couplants are special materials used in ultrasonic testing. They help ensure sound waves are accurately sent between test equipment and the material being checked. This is key for reliable test results in non-destructive examination, important in industries like manufacturing, aerospace, and energy.

How do the USA, Germany, and Japan influence the special couplant market?

These countries lead in growth due to their advanced manufacturing and R&D. They focus on eco-friendly and temperature-resistant products. This makes them leaders in the global market.

What challenges does the special couplant market face?

The market faces challenges like complex regulations and supply chain issues. Material shortages and the need for better performance in different applications add to these challenges.

How does globalization affect the special couplant supply chain?

Globalization makes the supply chain more complex. It creates links between suppliers, manufacturers, distributors, and users. Trade agreements and tariffs also affect product movement and pricing.

What are some emerging trends in special couplant technology?

New trends include eco-friendly and biodegradable products. There’s also a focus on temperature-resistant couplants and digital solutions. These trends align with Industry 4.0.

What applications primarily use special couplants?

Special couplants are used in many areas. This includes industrial manufacturing, energy sector inspections, and aerospace. They ensure precise and reliable testing.

How does the special couplant market comparison with other non-destructive testing methods?

Ultrasonic testing with special couplants often outperforms other methods. This is because it offers high accuracy and can inspect complex shapes better than others.

What role does innovation play in the U.S. special couplant market?

Innovation is key in the U.S. market. It drives the creation of premium products and improves performance. This keeps the U.S. competitive globally.

Are there any sustainability initiatives in the special couplant industry?

Yes, the industry is moving towards sustainability. It’s developing eco-friendly products and adopting green practices. This shift is important as industries worldwide become more sustainable.

How are Japan’s quality control standards different from other countries?

Japan’s standards are very high, thanks to practices like kaizen. This leads to the creation of ultra-high-performance couplants. These meet strict requirements, setting a high benchmark for others.