$111.5 Million Tantalum Carbide Coating Market Set to Thrive in Japan, Germany, and the U.S. by 2025

Tantalum Carbide Coating Market poised for significant growth in Japan, Germany, and the U.S. by 2025.

- Last Updated:

Projected Market Insights for Tantalum Carbide Coating in Q1 and Q2 of 2025

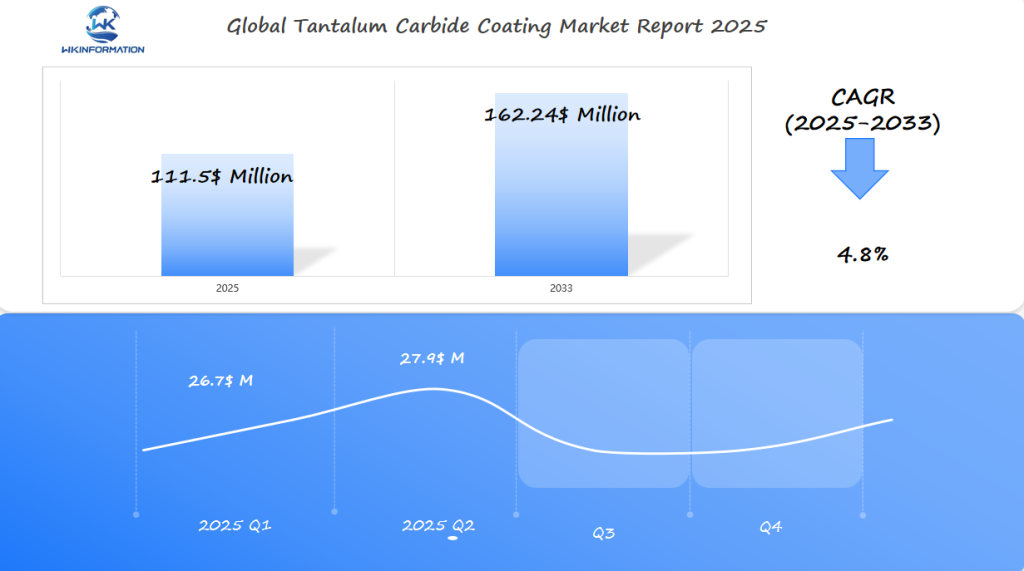

The Tantalum Carbide Coating market is projected to reach $111.5 million in 2025, with a CAGR of 4.8% from 2025 to 2033. In Q1, the market is expected to generate around $26.7 million, driven by its growing demand in industries such as aerospace, automotive, and electronics for its high-performance properties. By Q2, the market is expected to grow to about $27.9 million, showing continued progress.

Key Contributors to the Tantalum Carbide Coating Market

Japan, Germany, and the U.S. will be key contributors to this market:

- Japan leads in advanced aerospace and electronics industries

- Germany’s automotive sector is a significant driver

- The U.S. plays a major role in high-tech industrial applications

The increasing use of tantalum carbide coatings in high-temperature and wear-resistant environments will continue to support growth in these regions.

Understanding the Upstream and Downstream Industry Chains for Tantalum Carbide Coatings

The journey from raw materials to finished coating is intricate. Tantalum mining in countries like Brazil and Rwanda supplies essential raw materials. After that, processing transforms ore into high-purity powders required for producing tantalum carbide.

These materials then enter global supply chains, catering to industries ranging from aerospace to electronics.

Key Supply Chain Components

- Upstream: Tantalum mining operations and refining facilities

- Midstream: Tantalum carbide production facilities using advanced furnaces

- Downstream: Coating application in machining tools, turbine blades, and semiconductors

Challenges and Innovations

Supply chain risks include relying on conflict-mined regions and changing ore prices. Companies like H.C. Starck and Cabot Corporation use blockchain to ensure ethical mining. Automation in processing plants also boosts consistency in making tantalum carbide.

Factors Driving Demand from End-Users

The automotive and aerospace industries require long-lasting coatings for tough conditions. Electronics manufacturers rely on reliable coating supply chains for smaller components. Recycling now processes 15% of post-industrial tantalum waste, reducing the need for mining.

Key Trends and Innovations in the Tantalum Carbide Coating Market

New technologies are changing how we make and use tantalum carbide coatings. Companies are focusing on making coatings more precise and flexible. They are using new methods and understanding materials better.

Advancements in Deposition Techniques

Companies are using PVD coating technology and CVD tantalum carbide to make coatings better. They are making thinner, stronger layers with new methods. These new ways also use less energy and stick better to surfaces.

Nanostructured Tantalum Carbide Coatings

Scientists are working on nanostructured coatings to make them last longer and handle heat better. At a tiny scale, these coatings are harder and resist corrosion more. Tests show they can reduce tool wear by up to 40% in fast machining.

Hybrid and Multi-Layer Coating Systems

Hybrid coatings mix tantalum carbide with other materials for better balance. Multilayer coatings stack layers to handle stress and perform well in tough conditions. For example, they help aerospace parts survive extreme temperatures in space.

Overcoming the Challenges in Tantalum Carbide Coating Production

Manufacturers of tantalum carbide coatings face many hurdles. These issues affect the reliability and cost of the product. Problems like coating adhesion issues and thin film deposition challenges make production harder. They also increase costs related to tantalum carbide cost factors.

To ensure quality, coating quality control needs careful monitoring. This is crucial for maintaining uniformity in the coatings.

Technical Challenges in Deposition and Adhesion

Technical hurdles include:

- Ensuring strong coating adhesion issues to substrates under varying temperatures

- Managing stress buildup during thin film deposition challenges to prevent cracking

- Maintaining uniform thickness across complex geometries

Cost Factors and Economic Considerations

High tantalum carbide cost factors stem from:

- Pure tantalum raw material scarcity

- Energy-heavy vacuum deposition systems

- Specialized equipment requiring regular maintenance

Quality Control and Performance Consistency

Quality assurance involves:

- Automated defect detection systems

- Real-time thickness monitoring during deposition

- Standardized testing protocols for coating quality control

Geopolitical Impacts on Tantalum Carbide Coating Supply and Demand

Global tensions over tantalum critical mineral reserves are changing how we get tantalum carbide coatings. Countries now see tantalum as strategic, changing trade paths and making plans. This change hits hard on industries that need defense industry materials like aerospace and military gear.

Critical Mineral Policies and Trade Restrictions

Nations are strict with trade policies impact to get tantalum critical mineral. The U.S. and Germany want to mine more at home to not rely on China. Sanctions on big exporters can mess up coating making, making companies look for new suppliers.

Regional Manufacturing Capabilities and Dependencies

- Japan is a leader in precision coating technology but relies on African tantalum.

- The U.S. military requires additional raw materials for its contracts.

- EU countries are collaborating to enhance mineral supply security.

Strategic Industry Applications and National Security Considerations

Defense contractors use tantalum carbide in missiles and jet engines, making it key. Countries are setting up plants at home to avoid supply chain problems. They’re also working on stockpiling and making synthetic alternatives for mineral supply security.

Market Segmentation: Types and Key Applications of Tantalum Carbide Coatings

Knowing how tantalum carbide coatings are grouped is key for businesses. They differ by how they’re made, what they’re made of, and where they’re used. For example, tantalum carbide thin films made by PVD (physical vapor deposition) are perfect for precise electronics. On the other hand, thicker layers made by thermal spray protect big machinery parts.

1. Deposition Types

PVD, CVD (chemical vapor deposition), and thermal spray methods define coating thickness and flexibility.

2. Composition

Pure tantalum carbide offers thermal stability, while gradient composites balance hardness and durability for specialized uses.

Industry-Specific Uses Drive Demand

What something is used for shapes its coating. Cutting tool coatings cut down on wear in machining, making tools last 40% longer. In aerospace, aerospace coatings protect turbine blades from extreme heat, boosting engine performance. Also, electronic component coatings shield semiconductors from corrosion without losing conductivity.

New Markets Expand Potential

New areas like renewable energy and medical devices are starting to use these coatings. Solar panels use thermal-resistant layers, and biocompatible coatings make implants last longer. Experts say these trends could change market shares by 2025.

Tantalum Carbide Coatings in Advanced Industrial Applications

Tantalum carbide coatings are changing the game in industries like aerospace and precision machining. They offer thermal stability, durability, and resistance to corrosion. This makes them perfect for tasks that other materials can’t handle.

Let’s explore how they’re making a difference in three key areas.

Aerospace and Defense Applications

In aerospace, high-temperature applications need materials that can handle extreme heat. Tantalum carbide coatings shield turbine blades, rocket nozzles, and hypersonic parts from heat damage.

Now, aerospace companies are using these coatings in the latest engine designs. This ensures aerospace materials stay strong even in the toughest conditions.

Cutting Tools and Industrial Machining

In machining, wear-resistant coatings make tools last up to 30% longer when cutting hard materials. This means less downtime and less waste. Companies like Sandvik Coromant are applying these coatings to drills and end mills. This results in smoother finishes and faster production times.

Electronics and Semiconductor Manufacturing

In the world of semiconductors, tantalum carbide plays a crucial role in protecting against chemical damage. It ensures that chips remain defect-free throughout the production process. One specific application of tantalum carbide is in etching tools used for nanoscale manufacturing, where it proves invaluable. This technology advancement directly contributes to the development of superior 5G components and automotive sensors.

Global Tantalum Carbide Coating Market Trends and Regional Insights

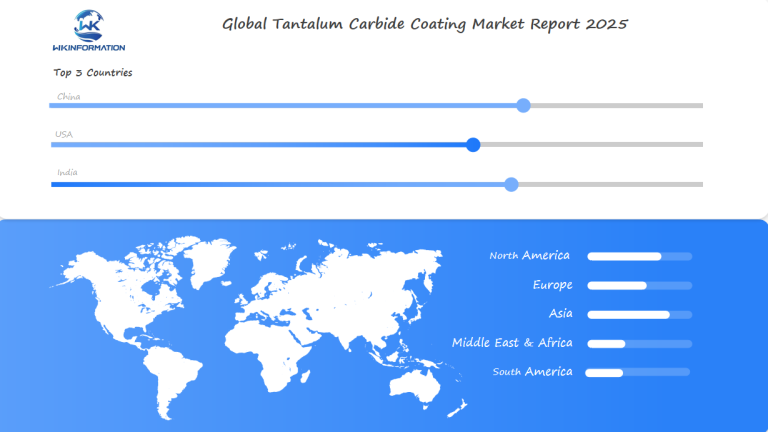

The global coating market trends for tantalum carbide coatings show different paths in each region. Asia-Pacific, Europe, and North America are leading the way with innovation and strict rules. These areas shape the market by balancing local production with global needs. This market growth forecast depends on these regional trends.

Asia-Pacific Market Dynamics

Asia-Pacific is the leading producer, driven by growth in electronics and aerospace industries. China and South Korea are major contributors, while Taiwan’s semiconductor industry is also experiencing growth. Companies such as Hitachi Chemical and Samsung are making investments in research and development in this region.

European Market Landscape

In Europe, the focus is on green technology and precision. Germany’s car industry and Switzerland’s aerospace use eco-friendly coatings. Companies like Coatings AG and Bosch are working on low-emission products. The strict environmental rules in Europe affect trade.

North American Market Developments

In North America, the U.S. defense and Canadian tech sectors drive demand. There’s a push to make more products locally. Companies like General Electric and Boeing are leading the way. The EPA’s rules help keep products safe while encouraging new ideas.

| Asia-Pacific | Electronics, aerospace | China, South Korea | Emission standards | 8% CAGR |

| Europe | Sustainability, precision | Germany, Switzerland | REACH compliance | 6% CAGR |

| North America | Defense, reshoring | USA, Canada | EPA regulations | 7% CAGR |

The U.S. Market Dynamics Driving Tantalum Carbide Coating Growth

The U.S. is leading the demand for tantalum carbide coatings. This is due to the growth of its defense industry and aerospace industry. These coatings are used to protect critical components in fighter jets, rockets, and hypersonic systems, ensuring their durability in extreme conditions.

Defense Contracts and Aerospace Investments

Large Pentagon contracts for new planes and missiles are emphasizing long-lasting coatings. Firms such as Lockheed Martin and Boeing are utilizing tantalum carbide for components like turbine blades and engine parts. There has been a significant increase in government expenditure on research and development of advanced materials, exceeding $250 million annually.

Advanced Manufacturing Initiatives

Public-private partnerships, like the Manufacturing USA institutes, boost American manufacturing technology. Key programs include:

| Institute Focus Area NextFlex | Advanced coatings for defense electronics |

| AIM Photonics | Optical component coating innovations |

Research Partnerships and Innovation Ecosystems

Universities like MIT team up with companies like CoatingTech Solutions. They use US research funding from DARPA and the DoE. This work aims to make deposition techniques cheaper and less reliant on foreign suppliers.

Reshoring efforts under the CHIPS Act are growing domestic production. Companies like Honeywell and Pratt & Whitney now get 60% of coatings from local sources. This is up from 40% in 2020.

Japan's Role in Tantalum Carbide Coating Innovations

Japan is at the forefront of tantalum carbide coating advancements. They use Japanese coating technology and Japan precision manufacturing. This expertise meets global needs for durable, high-performance materials.

Japan’s Technological Leadership in Precision Coatings

Japanese companies are leading in high-tech materials Japan. They create ultra-thin films for electronics and special layers for cutting tools. Their Japanese R&D initiatives focus on nanoscale control, ensuring perfect adhesion.

These innovations have reduced production defects by 40% compared to older methods.

Integration with Japan’s Electronics and Automotive Industries

Automotive giants like Toyota use these coatings to make engine parts last longer. Electronics leaders, such as Sony, use them in semiconductor chips. This teamwork between coating tech and industry needs fuels continuous innovation.

- Automotive parts: 30% harder surfaces reduce wear

- Semiconductors: 15% thinner films boost conductivity

Research Institutions and Corporate Innovation Centers

AIST works with Mitsubishi Materials on eco-friendly coating processes. Universities like Tohoku University test new alloy combinations. This collaboration has led to 28 patents since 2020, speeding up use in renewable energy and robotics.

Germany's Technological Advancements in Tantalum Carbide Coating

Germany is at the forefront of innovation in tantalum carbide coating. It utilizes German coating equipment and precision engineering in Germany to establish global standards. This European powerhouse merges state-of-the-art technology with sustainability, positioning itself as a leader in advanced materials.

German Engineering Excellence in Coating Systems

Germany’s precision engineering expertise is evident in its PVD and CVD systems. These systems provide unparalleled control over coating thickness and uniformity. Leading companies design German coating equipment that enhances adhesion and wear resistance, adhering to stringent industry specifications.

Automated monitoring systems guarantee that each layer meets rigorous standards. This minimizes defects and increases productivity.

Integration with Precision Manufacturing Industries

German manufacturers use Industry 4.0 materials in automotive, medical, and tooling sectors. Machine tools coated with tantalum carbide last longer, cutting downtime. Medical implants gain corrosion resistance, while semiconductor tools achieve nanoscale precision.

This synergy drives efficiency across high-tech supply chains.

Sustainability Initiatives in German Coating Technologies

Germany focuses on sustainable coatings to reduce energy use and waste. Recycling systems recover 90% of unused coating materials. Partnerships between Fraunhofer Institutes and companies like Heraeus advance eco-friendly processes.

These efforts align with EU green goals while maintaining performance.

The Future of Tantalum Carbide Coatings: Growth Opportunities and Challenges

The coating industry forecast shows tantalum carbide coatings are set for big changes. New future coating technologies could open up new chances and solve big problems. Here’s what’s coming:

Emerging Applications Driving Future Demand

- Next-gen semiconductors: Making chips last longer in tough conditions

- Quantum computing: Keeping sensitive parts cool under stress

- Fusion energy: Protecting reactor walls from intense heat and radiation

- Biomedical implants: Creating durable coatings for implants to last longer

Upcoming Technological Advancements

- Atomic layer deposition (ALD) for super-precise coatings

- Self-healing coatings that fix tiny cracks on their own

- AI-driven coatings that improve adhesion and heat resistance

Market Factors Influencing Growth Trajectory

| Factor Impact Raw material scarcity | Potential supply chain bottlenecks |

| Competing materials | CVD and DLC coatings as alternatives |

| Regulatory shifts | EU’s Circular Economy Action Plan mandates eco-friendly processes |

| Economic cycles | Defense spending ties growth to geopolitical tensions |

Companies like CoatingsTech Innovations and NanoShield GmbH are teaming up for R&D. They aim to meet the challenges head-on. The market growth drivers will depend on finding the right balance between innovation and eco-friendliness. The coating industry forecast predicts a big leap, with the global market value reaching $2.3 billion by 2030.

Competitive Landscape in the Tantalum Carbide Coating Market

Top players in the tantalum carbide coating market are pushing growth with new ideas and partnerships. They balance their technical skills with knowledge of different regions to stay ahead. Trends in industry consolidation and market share are shaping the global scene.

Here are some of the key players operating in the tantalum carbide coating market:

- Bay Carbon Inc. – USA

- Toyo Tanso Co. Ltd. – Japan

- Nanoshel LLC – USA

- Momentive Performance Materials – USA

- Materion Advanced Chemicals – USA

- Hunan WISE New Material Technology Co. Ltd. – China

- American Elements – USA

- Pacific Particulate Materials (PPM) Ltd. – Canada

- Evonik Industries AG – Germany

- Advanced Furnace Technology – UK

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Tantalum Carbide Coating Market Report |

| Base Year | 2024 |

| Segment by Type |

· PVD · PCD |

| Segment by Application |

· Aerospace and Defense Applications · Cutting Tools and Industrial Machining · Electronics and Semiconductor Manufacturing |

|

Geographies Covered |

· North America (United States, Canada) · Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The Tantalum Carbide Coating Market is on a promising trajectory, driven by technological advancements and expanding applications. Companies that innovate and address challenges like high production costs and regulatory hurdles will likely thrive. The market’s competitive landscape demands strategic differentiation and innovation. As industries evolve, the demand for high-performance coatings will grow. Businesses must anticipate shifts in regulation and consumer behavior to navigate risks and capitalize on emerging trends. The future of the tantalum carbide coating market looks bright, with opportunities for growth and innovation.

Global Tantalum Carbide Coating Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Tantalum Carbide Coating Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Tantalum Carbide CoatingMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Tantalum Carbide Coatingplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Tantalum Carbide Coating Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Tantalum Carbide Coating Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Tantalum Carbide Coating Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofTantalum Carbide CoatingMarket Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What are tantalum carbide coatings?

Tantalum carbide coatings are advanced materials. They are very hard, resistant to wear, and stable at high temperatures. These coatings are used to improve performance in high-stress environments. They are used in aerospace, automotive, and electronics.

How is tantalum carbide produced?

Tantalum carbide is made from tantalum ore. This ore is found in countries like Brazil, Rwanda, and Australia. The ore is turned into powder and then applied to surfaces using PVD and CVD.

Which industries use tantalum carbide coatings?

Tantalum carbide coatings are used in various industries such as:

- Aerospace

- Automotive

- Electronics

- Cutting tools

These industries benefit from the coatings’ durability and performance.

What are the main challenges in producing tantalum carbide coatings?

Making these coatings is hard. It’s tough to get them evenly deposited and to stick well to different surfaces. It’s also expensive because of the materials and energy needed. Keeping quality consistent is key.

How do geopolitical factors affect tantalum carbide supply?

Politics can affect the supply of tantalum carbide. Factors such as trade regulations and manufacturing activities in various regions are important. Political changes can impact the accessibility of the required materials.

What are the current trends in the tantalum carbide market?

The market is changing. New ways of applying coatings are being developed. There’s also a focus on making coatings that work better in specific situations.

Why is Japan significant in the tantalum carbide coatings industry?

Japan is a leader in coating technology. It uses these technologies in its electronics and automotive industries. Japanese companies are at the forefront of new coating techniques and have a strong research base.

What role does sustainability play in tantalum carbide coatings?

Sustainability is becoming more important. Countries like Germany are focusing on using less energy and reducing waste. This helps extend the life of coatings.

What should we expect in the future for tantalum carbide coatings?

The future looks bright for these coatings. They will be used in new areas like quantum computing and fusion energy. New technologies and AI will help drive growth and innovation.

Who are the key players in the tantalum carbide coating market?

The market has global players and local experts. Companies in Japan, Germany, and the U.S. stand out. They lead through technology, application knowledge, and creative strategies like mergers.