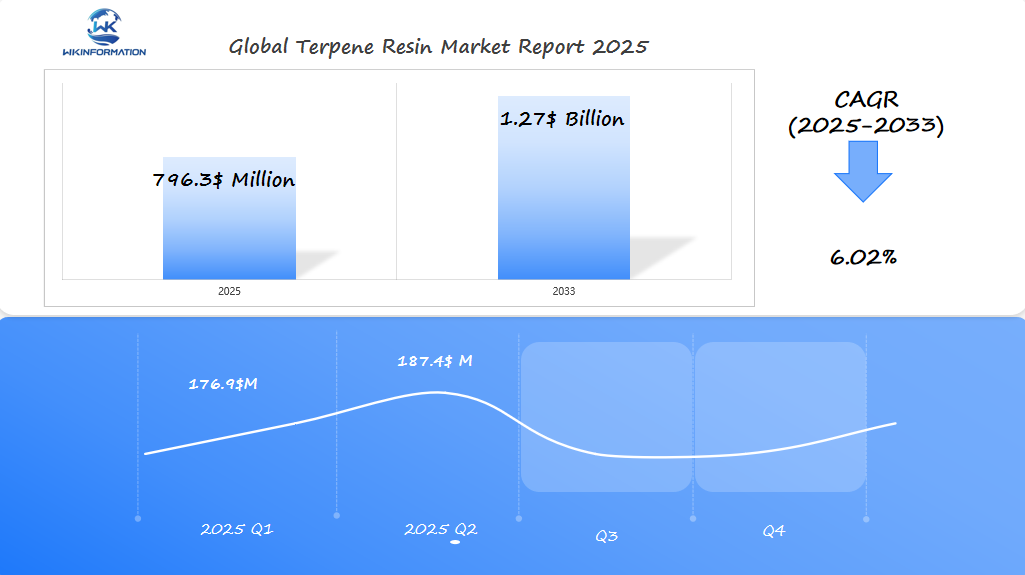

$796.3 Million Terpene Resin Market Expected to Surge in the U.S., China, and Brazil by 2025

Discover key trends in the Terpene Resin Market for 2025, including growth drivers, challenges, and applications in automotive, construction, and packaging.

- Last Updated:

Projected Market Insights for Terpene Resin in Q1 and Q2 of 2025

The Terpene Resin market is expected to reach $796.3 million in 2025, with a CAGR of 6.02% from 2025 to 2033. In Q1, the market is expected to generate around $176.9 million, driven by the growing demand for bio-based and sustainable resins in industries such as adhesives, coatings, and printing inks. By Q2, the market is forecasted to rise to approximately $187.4 million, as the demand for eco-friendly products and green technologies in manufacturing continues to grow.

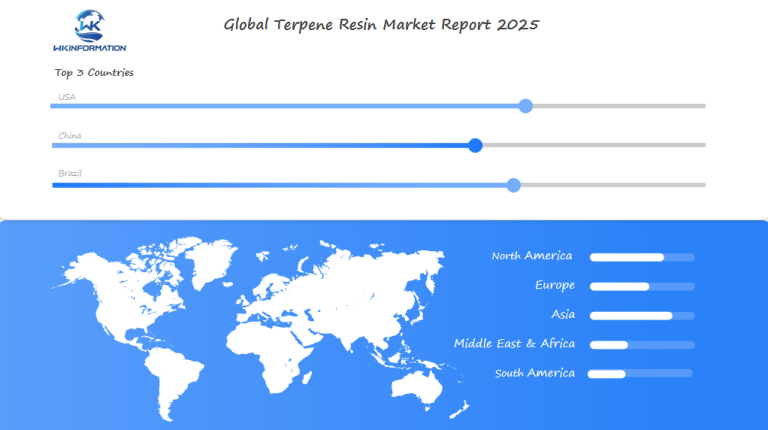

The U.S., China, and Brazil lead the global market. The U.S. is a key player in the production of high-performance resins for various industrial applications, while China drives the market with its manufacturing capabilities, and Brazil continues to support the market with its abundant natural resources for resin production. As the shift towards sustainability strengthens, the Terpene Resin market is expected to expand rapidly in these regions.

Key Takeaways

- The market value is projected to reach $796.3 million by 2025.

- The U.S., China, and Brazil are leading the regional growth.

- The adhesives and coatings industries are major users of terpene resins.

- Terpene resin efficiency helps in reducing production costs and waste.

- Sustainability trends are driving innovation in manufacturing processes.

Exploring the Upstream and Downstream Industry Chains for Terpene Resins

The growth of the resin market depends on the smooth working of both the upstream and downstream sectors. The upstream stages focus on getting raw materials, like tree resins and essential oils from plants. Companies like Arkema and Kraton turn these into base resins through distillation and polymerization.

Downstream uses drive demand across various industries. Terpene resins are mixed with additives to make adhesives or coatings for wood. Suppliers like Leuna-Werke and Hexion provide these to users in construction, cosmetics, and consumer goods. Collaboration between suppliers and processors is key to keeping product quality high, which boosts the resin market.

Key Activities in Upstream and Downstream

- Upstream: Raw material extraction, chemical processing, and refining

- Downstream: Manufacturing, formulation, and distribution to end markets

Efficiency in the supply chain affects prices and innovation. It’s important to have sustainable sourcing and partnerships between suppliers and chemical firms. As industries like packaging move towards eco-friendly materials, this could open up new growth paths for the resin market in the future.

Key Trends in Terpene Resin Applications Across Multiple Industries

Terpene resins are changing the game in many fields because they’re flexible, good-for-the-planet, and sustainable. They are becoming a big deal in sustainable resins for adhesives, replacing old petroleum-based ones. These new resins bond well in packaging, construction, and electronics, all while being kind to the environment.

1. Coatings Industry

Terpene resins are being mixed into wood and paper coatings. This makes them last longer and cuts down on harmful chemicals.

2. Rubber Production

Car and tire makers are using terpene resins. It makes rubber more flexible and heat-resistant, reducing the need for synthetic additives.

3. Beauty and Packaging

The move towards sustainable resins is also seen in biodegradable packaging and cosmetics.

“Customers demand materials that balance performance and planet-friendly practices. Terpene resins meet this need head-on.”

Innovation is all about making things better while being gentle on the planet. Companies are working hard to create more plant-based terpene blends. This isn’t just a trend; it’s a response to the world’s need for greener products. Terpene resins are becoming key players in making production more eco-friendly around the globe.

Challenges in the Production and Sourcing of Terpene Resins

Manufacturers face many challenges when making and sourcing terpene resins. The costs of raw materials can fluctuate significantly, and delays in the supply chain can impact industrial resin applications. Additionally, ensuring high quality adds to the complexity.

Some challenges include:

- Unreliable raw material supplies from natural sources

- Price swings in feedstocks like pine and citrus peels

- Technical challenges in achieving consistent purity levels

| Challenge | Solution |

| Supply shortages | Secure multiple global suppliers |

| Cost instability | Long-term supplier contracts |

| Production complexity | Invest in automation and R&D |

Companies work with suppliers to make supply chains more stable. New ways to make terpene resins improve quality for industrial resin applications. Working together and using new technology help solve these issues.

Geopolitical Impacts on the Terpene Resin Supply Chain

Global politics can affect the resin supply chain in big ways. Disputes between big countries like China and the U.S. can slow down shipments. This makes things more expensive for those who make products.

When there’s trouble in places where resin is found, it’s hard to get the raw materials. And when there are trade barriers, like tariffs, it’s harder to move goods across borders.

Key Factors Influencing the Resin Supply Chain

- Trade policies: Export restrictions or import taxes alter production costs and delivery timelines.

- Regional conflicts: Unstable regions hinder logistics, raising risks for suppliers and buyers.

- Regulatory changes: New environmental or quality mandates force producers to adjust processes rapidly.

Market volatility requires proactive strategies to secure resin supply chain resilience.

In the U.S., companies often get resin from China and Brazil. This makes them sensitive to trade issues. For instance, sanctions could change where goods are shipped, making things take longer.

It’s important for producers to keep an eye on policies in important areas. Talking openly between suppliers and buyers helps deal with risks. Knowing these issues helps businesses stay steady, even when things change.

Market Segmentation: Types and Applications of Terpene Resins

Terpene resins come in many forms and uses, making different market segments. They are made from various sources like pine trees or paper byproducts. Each type has its own purpose, from making adhesives to helping in medicines.

Types of Terpene Resins

- Gum Rosin: Common in packaging and wood adhesives due to its clean, light color.

- Wood Rosin: Used in high-temperature applications like hot-melt adhesives.

- Tall Oil Rosin: Key in inks and coatings for its stability during printing processes.

Demand for Terpene Resins by Industry

Demand for terpene resins varies by industry:

- In adhesives, they replace petroleum-based products, fitting eco-friendly trends.

- Coatings benefit from their weather resistance.

- Medicines use purified resins in pill production.

The geopolitical resin impact influences which segments grow the most. For instance, stricter environmental policies in the U.S. increase demand for bio-based resins. Meanwhile, Asia-Pacific regions focus on cost-effective industrial grades.

How Manufacturers Create Products Based on Regional Needs

Manufacturers create products based on these regional needs. Knowing about segmentation helps businesses find markets where innovation and rules open up opportunities. As industries change, so do the trends in segmentation, influenced by technology and global trade.

Terpene Resins in Adhesives, Coatings, and Rubber Industries

Terpene resins are changing the game in adhesives, coatings, and rubber. They bring together natural and high-performance qualities. This mix is reshaping how we use materials in industry.

In adhesives, they help create strong bonds for packaging and building. This means we use less synthetic stuff. Coatings get better at blocking UV rays and lasting longer. Rubber products, like tires, become more elastic and durable.

Applications of Terpene Resins

- Adhesives: Strengthen wood and paper bonding with renewable materials.

- Coatings: Provide scratch-resistant layers for automotive and industrial surfaces.

- Rubber: Enhance flexibility and thermal stability in high-stress environments.

Now, making things greener is a top priority. Eco-friendly adhesives and rubber blends help cut down on waste. The auto and packaging worlds are jumping on this bandwagon to meet green goals.

As more people want these green products, makers are working on cheaper, better options. Terpene resins are making tires last longer and helping create lighter, stronger stuff. They’re pushing progress in every area.

Global Insights into the Terpene Resin Market

Improvements in terpene resin efficiency are changing how markets work around the world. In places like Asia, Europe, and North America, producers focus on being green to keep up with demand. They’re finding new ways to make terpene resin more efficient, which saves money and reduces waste.

Efficiency gains in terpene resin production are critical to maintaining competitiveness in global supply chains.

- Adoption of AI-driven analytics to refine manufacturing processes

- Partnerships between suppliers and end-users to align quality standards

- Investment in R&D for bio-based additives that enhance resin performance

In Europe, there’s a big push for eco-friendly resins. But in Asia, it’s all about making lots of them. Still, everyone wants to make terpene resin more efficient to fix supply chain problems. Now, tools help buyers see how different suppliers stack up, based on things like how much they make and how much energy they use.

Big names like Basf and Arkema show how making terpene resin better helps keep prices steady, even when raw materials are hard to get. As more industries, from packaging to cars, use these resins, the need for better, greener options keeps growing.

U.S. Market Demand for Terpene Resins in Industrial Applications

The resin market growth in the U.S. is on the rise. This is thanks to growing needs in adhesives, coatings, and rubber. Terpene resins are becoming more popular because they are durable and cost-effective.

| Industry Sector | Key Applications | Demand Drivers |

| Adhesives | Packaging, construction | High-performance bonding solutions |

| Coatings | Wood finishing, automotive | Environmental regulations favoring eco-friendly materials |

| Rubber | Tire manufacturing, insulation | Increased demand for renewable resource-based products |

U.S. companies are focusing on R&D to meet sustainability goals. The resin market growth shows a move towards bio-based materials. Terpene resins help reduce fossil fuel use in making products. This fits with federal goals for green technologies.

- Automotive sector: 22% of U.S. resin demand comes from coatings for vehicle finishes

- Construction: Rising use in sealants and insulation materials

- Packaging: Growth in eco-friendly adhesives for disposable products

There are chances for more partnerships between resin makers and industrial users. These partnerships offer solutions that are both affordable and good for the environment. The U.S. is a key place for new ideas in the resin world.

China’s Growth in Terpene Resin Production and Innovation

China is leading the way in terpene resin technology. Companies like Nantong Jicheng Chemical and Sinopec are making sustainable resins. They use plant-based materials and efficient methods to meet eco-friendly needs.

Key Developments in China’s Sustainable Resin Industry

- Advanced distillation systems cut waste by 30%.

- Government grants support R&D for bio-based resin formulations.

- Export growth targets set to double by 2025.

Comparison of Traditional Resins and Sustainable Resins in China

| Traditional Resins | Sustainable Resins |

| High fossil fuel use | Renewable raw materials |

| Higher carbon emissions | 60% lower emissions |

“China’s factories are pioneers in greener resin tech,” said a 2023 industry report. “Innovation here sets global standards.”

China’s “Made in China 2025” plan focuses on eco-friendly manufacturing. Factories now recycle 95% of byproducts, cutting landfill waste. This makes China a leader in both volume and environmental care.

Brazil’s Role in Terpene Resin Supply and Export

Brazil is becoming a major player in the global terpene resin market. It uses its vast natural resources and strategic location to its advantage. The country’s pine forests are a treasure trove for raw materials needed to make resins. These resins are used in industrial resin applications in many manufacturing fields.

Factors Contributing to Brazil’s Growth in Terpene Resin Supply and Export

- Resource-rich ecosystems: Pine plantations cover millions of hectares, providing consistent raw material for resin production.

- Strategic export hubs: Ports in Paraná and São Paulo enable cost-effective shipping to North America and Europe.

- Strong industrial ties: Partnerships with global manufacturers ensure resins meet standards for adhesives, coatings, and rubber products.

Brazil’s resins are crucial for industries like packaging and construction. They are perfect for industrial resin applications that need to withstand high temperatures. Companies like Rio Polymers and Brazil Resin Co. are increasing their exports to meet growing demand.

Government support for agro-industrial sectors is helping production grow. This growth makes Brazil a key player in global supply chains. As the need for eco-friendly materials increases, Brazil’s importance will only grow.

The Future of Terpene Resins: Bio-based and Sustainable Trends

The terpene resin industry is moving towards eco-friendly practices. Companies are now focusing on reducing waste and carbon footprints. This shift aims to meet global sustainability goals. Innovations in bio-based feedstocks and renewable energy are driving this change.

Current Trends in Sustainability

Here are some current trends in the terpene resin industry:

- Manufacturers are adopting circular production methods to recycle byproducts.

- Renewable raw materials like plant-based oils are replacing fossil fuel-derived inputs.

- Transparency tools track environmental impacts from sourcing to delivery.

“Sustainability isn’t optional—it’s essential for long-term growth,” says a 2023 industry report. “Investing in green tech strengthens market appeal and reduces risks.”

Industry Examples

Companies like Arakawa Chemicals and Kraton Corporation are using solar power and water recycling. These changes help cut costs and meet growing demand for eco-friendly products. The resin supply chain now focuses on traceable, ethical sourcing to meet consumer expectations.

Future Projections

By 2025, bio-based resins could make up 30% of the market. Sustainable practices boost brand reputation and open up green markets. Companies that adapt quickly will lead in this changing industry.

Competitive Dynamics in the Terpene Resin Market

- Mangalam Organics Limited – Mumbai, India

- Yasuhara Chemical Co. Ltd – Kobe, Japan

- Ingevity – North Charleston, South Carolina, USA

- Kraton Corporation – Houston, Texas, USA

- Baolin Chemical Industry Co. Ltd – Hangzhou, China

- Lesco Chemical Company – Hangzhou, China

- Arakawa Chemical Industries Ltd – Osaka, Japan

- Xinyi Sonyuan Chemical Co. Ltd – Xinyi, Jiangsu, China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Terpene Resin Market Report |

| Base Year | 2024 |

| Segment by Type | ·Liquid Type ·Solid Type |

| Segment by Application | ·Ink, Paint and Coating ·Hot Melt and Pressure Sensitive Adhesives ·Rubber and Tape ·Food Industry ·Other |

| Geographies Covered | · North America (United States, Canada)

· Europe (Germany, France, UK, Italy, Russia) · Asia-Pacific (China, Japan, South Korea, Taiwan) · Southeast Asia (India) · Latin America (Mexico, Brazil) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The terpene resin market is expected to reach $796.3 million by 2025. This growth is due to fast progress in resin innovation and increasing demand worldwide. The U.S., China, and Brazil are leading in production and use, thanks to new applications in adhesives, coatings, and eco-friendly materials.

However, sourcing challenges and geopolitical changes are present. Yet, the industry is overcoming these hurdles with technology and partnerships.

Resin innovation is changing many fields, from packaging to clean energy. Companies like Ashland and Eastman are focusing on bio-based resins for green standards. Brazil’s exports are also growing, making it a major supplier.

This shows great opportunities for makers and investors to support sustainability and tap into new markets.

As competition grows, it’s crucial to keep up with supply chain and policy changes. Whether you’re a new company or a big player, the market offers chances to innovate and care for the environment. Watch how resin innovation will change industries and get ready to lead the way.

Global Terpene Resin Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Terpene Resin Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Terpene ResinMarket Segmentation Overview

Chapter 2: Competitive Landscape

- Global Terpene Resinplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Terpene Resin Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Terpene Resin Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Terpene Resin Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofTerpene Resin Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is the terpenes resin market and why is it important?

The terpenes resin market deals with natural terpenes and their products. It’s used in adhesives, coatings, and cosmetics. It’s growing because people want eco-friendly and bio-based products.

What are the main uses of terpene resins?

Terpene resins have a wide range of applications. They are commonly found in:

- Adhesives

- Coatings

- Rubber products

- Inks

These industries benefit from the unique properties of terpene resins, which enhance the quality of their products.

Which regions are leading in terpene resin production?

The top producers are the United States, China, and Brazil. They lead because of their advanced production and growing markets.

What challenges are faced in terpene resin production?

Making terpene resins can be tough. Costs of raw materials change, and supply chains can be uncertain. Also, making them can be tricky.

How do geopolitical factors affect the terpene resin supply chain?

Politics can change how terpene resins are made and sold. Trade policies and stability in regions affect prices and availability. This makes the supply chain complex.

What trends are emerging in the terpene resin market?

The market is moving towards being more sustainable. New ways of making products are being tried. There’s a focus on using terpene resins in bio-based products.

What role does Brazil play in the terpene resin market?

Brazil is becoming more important in the market. It has lots of natural resources and good export conditions. Its location helps it in the global supply chain.

What is the future outlook for the terpene resin market?

The market looks promising for the future. It will focus more on bio-based and sustainable products. New technologies will help meet the demand for eco-friendly products.

How can companies improve their terpene resin sourcing strategies?

Companies can enhance their terpene resin sourcing strategies by collaborating with trusted suppliers. It’s also beneficial to source locally and diversify suppliers to mitigate issues tied to global supply chains.