2025 Vacuum Eutectic Reflow Oven Market Insights: USA, China, and Japan Leading the Growth Worth $143.77 Million

Explore the Vacuum Eutectic Reflow Oven market trends, growth drivers, and industry analysis, with a focus on technological advancements and market dynamics.

- Last Updated:

Market Forecast for Vacuum Eutectic Reflow Oven in 2025: Q1 and Q2 Predictions

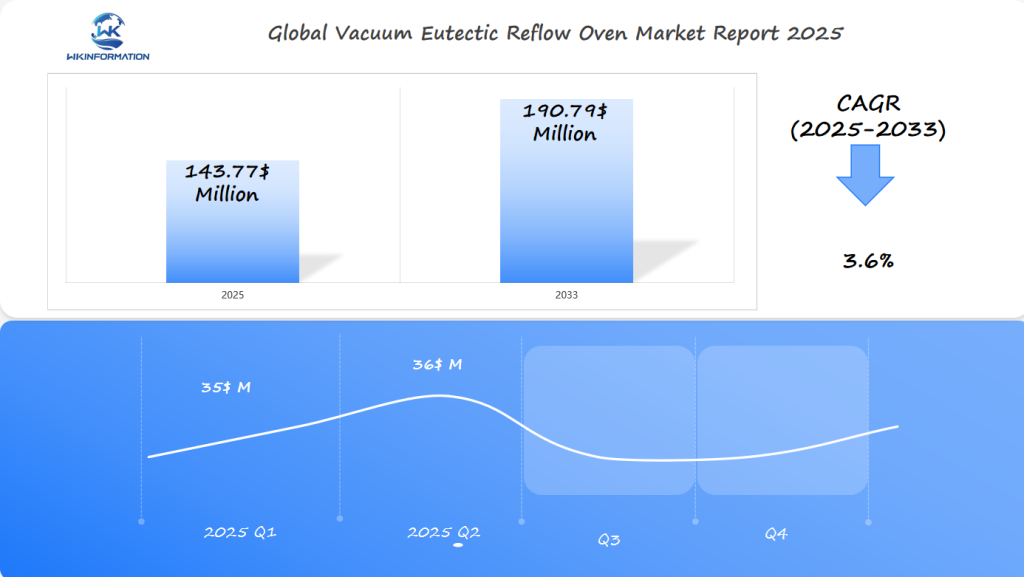

The Vacuum Eutectic Reflow Oven market is projected to reach $143.77 million in 2025, with a CAGR of 3.6% from 2025 to 2033. Q1 is expected to account for around $35 million, with Q2 showing a slight increase to $36 million. Growth is driven by the need for precise soldering and advanced manufacturing processes in electronics and semiconductor industries.

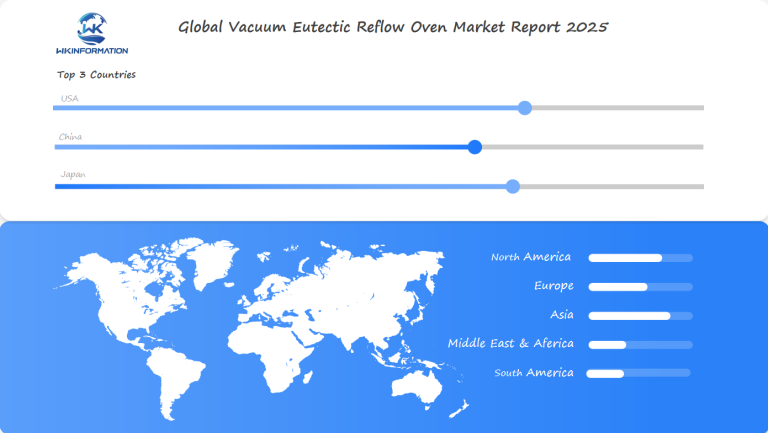

Key regions, including the USA, China, and Japan, are anticipated to lead the market, as their strong electronics manufacturing sectors and technological advancements push the demand for high-performance reflow ovens. With the ongoing miniaturization of electronic components and the increasing complexity of printed circuit boards (PCBs), the need for advanced soldering techniques that ensure high reliability in critical electronic devices is on the rise. Additionally, emerging technologies in areas like 5G and IoT will continue to drive the demand for innovative manufacturing processes, which vacuum eutectic reflow ovens support.

Key Takeaways

- Global market value projected at $143.77 million by 2025

- Asia-Pacific region leads market expansion

- Key technological advancements in precision soldering

- Strong growth in semiconductor and electronics sectors

- Increasing demand for miniaturized electronic components

Upstream and Downstream Analysis of the Vacuum Eutectic Reflow Oven Market

The vacuum eutectic reflow oven market is complex. It links raw materials, component makers, and users in the electronics world. Knowing these links is key to understanding growth and new tech.

Raw Material Suppliers and Component Manufacturers

Raw materials are vital for making vacuum eutectic reflow ovens. The chain starts with makers of high-quality parts needed for precise heat processing tools.

- Advanced ceramic materials

- High-temperature resistant alloys

- Precision electronic control systems

- Specialized thermal insulation components

End-Users and Applications in Electronics Industry

The market’s end-users are in the electronics making world. These advanced machines are key to complex making processes.

| Industry Sector | Primary Applications |

| Semiconductor Manufacturing | PCB Assembly, Chip Packaging |

| Consumer Electronics | Mobile Device Production |

| Automotive Electronics | Advanced Electronic Control Units |

More and more electronics makers use vacuum eutectic reflow ovens. They help with exact soldering and part joining. These machines are vital for today’s electronic gadgets.

Key Trends Shaping the Vacuum Eutectic Reflow Oven Market in 2025

The vacuum eutectic reflow oven market is changing fast. New technologies and trends are leading the way. Electronics makers are looking for better ways to make things.

Now, we see a big move towards better manufacturing. New tech is changing how we make and solder electronic parts.

Technological Advancements in Reflow Soldering

Reflow soldering has gotten a lot better. Some big changes include:

- Improved temperature control systems that are super precise

- Using vacuum to help solder, making fewer mistakes

- Smart systems that check quality as it happens

Increasing Demand for High-Density Interconnect (HDI) PCBs

More people want HDI PCBs because of the need for smaller devices. Things like phones, tablets, and smartwatches are driving this need.

Companies are spending a lot on HDI PCB tech. They want to make:

- Smaller electronics

- More parts in a smaller space

- Better signal quality

New tech and market needs are opening up big chances in the vacuum eutectic reflow oven field.

Restrictions and Challenges in the Vacuum Eutectic Reflow Oven Market

The vacuum eutectic reflow oven market has big challenges. These affect both manufacturers and those in the electronics industry. These hurdles make it hard for these technologies to be widely used and adopted.

Companies face many obstacles when trying to use new reflow soldering tech. One big problem is the cost. This is especially tough for smaller electronics makers who don’t have a lot of money.

High Initial Investment Costs

Getting started with vacuum eutectic reflow ovens is very expensive. The costs include:

- Advanced equipment

- Specialized technical setup

- Training for staff

- Expenses for upkeep and calibration

Technical Complexities in Operation and Maintenance

There are also technical challenges in the vacuum eutectic reflow oven market. Keeping the temperature just right is key. This helps avoid damage from heat and prevents oxidation of solder.

| Technical Challenge | Potential Impact |

| Temperature Variation | Risk of component thermal shock |

| Solder Joint Integrity | Compromised electronic performance |

| Production Environment Control | Potential contamination risks |

Companies need to spend a lot on sophisticated operational protocols. This is to deal with these technical issues. It helps ensure quality and consistency in production.

Geopolitical Impact on the Vacuum Eutectic Reflow Oven Industry

The global vacuum eutectic reflow oven market is changing a lot. This is because of complex geopolitical factors. Trade policies and where things are made are changing the industry a lot.

Big economic powers are causing big changes in how things are made. Trade policies and tariffs are making companies think about their production and supply chains differently.

Trade Policies and Tariffs Reshaping Market Dynamics

International trade changes have made things exciting for vacuum eutectic reflow oven makers. Here are some key points:

- Higher tariffs between the USA and China are messing with supply chains

- New places are becoming important for making things because of trade rules

- Production is being moved around to different places for better chances

Regional Manufacturing Shifts

Manufacturing is moving around a lot in the vacuum eutectic reflow oven world. Countries are moving their electronics making to get ahead.

| Region | Manufacturing Strategy | Key Impact |

| USA | Reshoring Electronics Production | More things made in the USA |

| China | Technological Innovation | Better at making things |

| Japan | Advanced Manufacturing Technologies | Makes things very precisely |

These changes are making the vacuum eutectic reflow oven market very complex and changing fast.

Types of Vacuum Eutectic Reflow Ovens and Their Technological Developments

The vacuum eutectic reflow oven market is always changing. It’s thanks to new soldering technologies that meet the needs of making electronics. Each type of reflow oven has special features for precise soldering in different electronic projects.

Today’s reflow oven technologies have changed how we make electronics. They use new designs and better performance. This helps solve big problems in soldering and managing heat.

Convection Reflow Ovens

Convection reflow ovens are a big step forward in soldering. They use hot air to heat components evenly.

- Precise temperature control

- Consistent thermal distribution

- Suitable for complex PCB designs

Vapor Phase Reflow Ovens

Vapor phase reflow ovens have special benefits. They create a clean environment that protects components from oxidation during soldering.

| Feature | Benefit |

| Condensation Heating | Uniform Temperature Distribution |

| Inert Atmosphere | Reduced Oxidation Risk |

| Precise Thermal Profile | Enhanced Solder Quality |

Infrared Reflow Ovens

Infrared reflow ovens use electromagnetic waves for precise heating. This makes soldering fast and accurate for many electronic projects.

- Direct component heating

- Quick thermal transfer

- Ideal for dense circuit boards

The ongoing improvement in reflow oven types shows the electronics industry’s dedication. It’s all about better soldering technologies and making things more precise.

Applications of Vacuum Eutectic Reflow Ovens in Electronics and Semiconductor Industries

Vacuum eutectic reflow ovens are key in today’s electronics world. They change how we package semiconductors and assemble Surface Mount Technology (SMT). These ovens help make top-notch electronic parts for many fields.

These ovens are super precise. They help make soldering in complex electronics better and more reliable. They support many important ways to make products.

Surface Mount Technology (SMT) Assembly

SMT assembly is a big use for vacuum eutectic reflow ovens. They work great in attaching electronic parts to circuit boards. The benefits are:

- Less stress on small parts

- Better soldering

- Less chance of part damage

- More reliable circuit boards

Ball Grid Array (BGA) Packaging

Ball Grid Array packaging also gets a big boost from these ovens. They help make detailed, high-density connections with great accuracy.

Flip Chip Technology

Flip chip tech uses these ovens to make things even smaller and better. They allow for exact alignment and bonding of tiny electronic parts.

Vacuum eutectic reflow ovens keep improving electronics making. They offer advanced thermal control and precise settings.

Global Market Insights: Vacuum Eutectic Reflow Oven Market Performance Worldwide

The global market for vacuum eutectic reflow ovens is changing fast in 2025. New technologies and more electronics being made are pushing growth in many areas.

Looking at the global market size, we see big growth in semiconductors and electronics. This opens up new chances for innovation and getting into new markets.

Regional Market Share Analysis

Different parts of the world have their own market traits. The U.S., China, and Japan are key players. They bring their own tech and manufacturing styles to the table.

“The vacuum eutectic reflow oven market represents a critical technological frontier in advanced electronics manufacturing” – Industry Research Report

More money being spent on research, and a growing need for advanced PCBs are driving growth. Electronics makers focus on precise soldering to improve quality and speed up production.

USA Vacuum Eutectic Reflow Oven Market: Growth, Insights, and Forecasts

The United States is leading in vacuum eutectic reflow oven technology. This is boosting growth in the electronics manufacturing sector. The demand for advanced reflow soldering solutions is rising in various tech fields.

Market leaders are changing the tech scene with new ideas. They are spending a lot on research and development. This is to make reflow oven systems more efficient and accurate.

Market Players Driving Innovation

- Advanced semiconductor equipment manufacturers

- Electronics manufacturing service providers

- Specialized equipment engineering companies

Technological Innovation and R&D Activities

In the USA, R&D is focused on the next big thing in vacuum eutectic reflow ovens. Research is all about:

- Improving thermal management systems

- Creating precise temperature control

- Using artificial intelligence for better processes

The market is set to grow a lot. Specialized equipment manufacturers are putting a lot of money into new tech. These advancements will make production more efficient and cheaper for the electronics industry.

The future of vacuum eutectic reflow oven technology in the USA lies in continuous technological advancement and strategic industry partnerships.

China Vacuum Eutectic Reflow Oven Market: Key Developments and Innovations

The China market for vacuum eutectic reflow ovens is changing the game in electronics making. China is leading the way in new soldering tech.

China’s focus on top-notch manufacturing has boosted its vacuum eutectic reflow oven field. The country’s electronics sector has seen big tech leaps. This is thanks to:

- Big investments in research and development

- Strong backing from the government for high-tech making

- More demand for complex electronic parts

Manufacturing Capabilities and Export Trends

Chinese makers of vacuum eutectic reflow ovens have grown a lot. Now, Chinese makers compete worldwide with precise, advanced soldering gear. Their exports are on the rise, making them a big player globally.

Government Initiatives and Industry Support

Government plans have helped the vacuum eutectic reflow oven market a lot. Key programs include:

- Money for semiconductor and electronics research

- Grants for tech innovation

- Help for local makers to create new soldering tech

These efforts have made China a key player in the vacuum eutectic reflow oven market. We can expect more growth and new tech in the future.

Japan Vacuum Eutectic Reflow Oven Market: Market Trends and Forecasts

The Japanese market for vacuum eutectic reflow ovens is a leader in electronics manufacturing. Known for its precision engineering, Japan keeps pushing the limits of soldering technology. This innovation is changing how electronics are made worldwide.

Japan’s market trends show important advancements in vacuum eutectic reflow oven technology:

- Advanced high-precision soldering capabilities

- Specialized solutions for automotive and industrial electronics

- Integration of cutting-edge semiconductor packaging techniques

Technological Leadership and Innovation

Japanese makers are leading the way in new reflow oven technologies. Technological leadership comes from deep research and development. They focus on making these ovens better and more reliable.

Key areas of innovation are:

- Miniaturization of electronic components

- Enhanced thermal management systems

- Intelligent process control mechanisms

Market Challenges and Opportunities

Even with tough competition, market opportunities for vacuum eutectic reflow ovens in Japan are strong. The rise of 5G, IoT devices, and advanced semiconductors opens up big growth chances for creative makers.

Strategic moves include tapping into new electronics areas. Also, developing unique soldering solutions for complex manufacturing needs.

What's Next for the Vacuum Eutectic Reflow Oven Market in 2025?

The vacuum eutectic reflow oven market is on the verge of big changes. As electronics get better, makers are looking for new ways to meet needs. We’re seeing a big change in how we solder electronics.

New tech is changing the world of vacuum eutectic reflow ovens. Scientists are working on new solutions that will change how we make electronics.

Emerging Technologies and Future Applications

Here are some new techs that will help the market grow:

- Advanced AI-driven process control systems

- Laser-assisted reflow technologies

- Quantum computing packaging capabilities

- Miniaturized electronic device integration

Market Predictions and Growth Opportunities

The market is set to grow a lot in different areas. Precision manufacturing and advanced electronic packaging will lead the way. There are big chances for growth in:

- Semiconductor manufacturing

- Aerospace electronics

- Medical device technology

- Advanced telecommunications infrastructure

Companies are spending a lot on research to make better vacuum eutectic reflow oven tech. The future looks bright for making electronics better.

Competitive Landscape of the Vacuum Eutectic Reflow Oven Market

-

Heller Industries —— USA

-

Palomar Technologies —— USA

-

SMT Wertheim —— Germany

-

PINK GmbH —— Germany

-

Centrotherm Eco Systems LLC —— USA

-

Origin —— USA

-

Shinko Seiki —— Japan

-

Quick Intelligent —— China

-

Yantai Huachuang Intelligent Equipment —— China

Overall

| Report Metric | Details |

|---|---|

| Report Name | Global Vacuum Eutectic Reflow Oven Market Report |

| Base Year | 2024 |

| Segment by Type |

|

| Segment by Application |

|

| Geographies Covered |

|

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |

The vacuum eutectic reflow oven market is growing fast. It’s expected to hit $143.77 million by 2025. This growth is driven by the need for advanced electronics in places like the United States, China, and Japan.

There have been big steps forward in reflow soldering. This is especially true for making high-density interconnect (HDI) printed circuit boards. But, there are still challenges like high costs and complex operations.

Strategic Market Insights

Experts say investing in research and development is key. Companies need to make more efficient vacuum eutectic reflow ovens. These should solve current problems and prepare for future needs in electronics.

Future Market Perspective

The future looks bright for vacuum eutectic reflow oven technology. To stay ahead, companies should form partnerships, keep innovating, and adapt to new manufacturing ways. Staying ahead of new tech trends will help leaders in this fast-changing field.

Global Vacuum Eutectic Reflow Oven Market Report (Can Read by Free sample) – Table of Contents

Chapter 1: Vacuum Eutectic Reflow Oven Market Analysis Overview

- Competitive Forces Analysis (Porter’s Five Forces)

- Strategic Growth Assessment (Ansoff Matrix)

- Industry Value Chain Insights

- Regional Trends and Key Market Drivers

- Vacuum Eutectic Reflow Oven MarketSegmentation Overview

Chapter 2: Competitive Landscape

- Global Vacuum Eutectic Reflow Ovenplayers and Regional Insights

- Key Players and Market Share Analysis

- Sales Trends of Leading Companies

- Year-on-Year Performance Insights

- Competitive Strategies and Market Positioning

- Key Differentiators and Strategic Moves

Chapter 3: Vacuum Eutectic Reflow Oven Market Segmentation Analysis

- Key Data and Visual Insights

- Trends, Growth Rates, and Drivers

- Segment Dynamics and Insights

- Detailed Market Analysis by Segment

Chapter 4: Regional Market Performance

- Consumer Trends by Region

- Historical Data and Growth Forecasts

- Regional Growth Factors

- Economic, Demographic, and Technological Impacts

- Challenges and Opportunities in Key Regions

- Regional Trends and Market Shifts

- Key Cities and High-Demand Areas

Chapter 5: Vacuum Eutectic Reflow Oven Emerging and Untapped Markets

- Growth Potential in Secondary Regions

- Trends, Challenges, and Opportunities

Chapter 6: Product and Application Segmentation

- Product Types and Innovation Trends

- Application-Based Market Insights

Chapter 7: Vacuum Eutectic Reflow Oven Consumer Insights

- Demographics and Buying Behaviors

- Target Audience Profiles

Chapter 8: Key Findings and Recommendations

- Summary ofVacuum Eutectic Reflow Oven Market Insights

- Actionable Recommendations for Stakeholders

Access the study in MULTIPLEFORMATS

Didn’t find what you’re looking for?

TALK TO OUR ANALYST TEAM

Need something within your budget?

NO WORRIES! WE GOT YOU COVERED!

Call us on: +1-866-739-3133

Email: infor@wkinformation.com

What is a vacuum eutectic reflow oven?

A vacuum eutectic reflow oven is a high-tech soldering tool for making electronics. It controls temperature precisely and forms top-notch solder joints in a vacuum. These ovens are key for making reliable connections in complex electronics, especially in semiconductors and PCBs.

Why are vacuum eutectic reflow ovens important in electronics manufacturing?

These ovens are vital for their top-notch soldering of tiny electronic parts. They ensure even heating, less oxidation, and better solder joints. This is crucial for making high-density PCBs and advanced packages like BGA and Flip Chip.

What is the projected market value for vacuum eutectic reflow ovens by 2025?

The market is expected to hit $143.77 million by 2025. This growth comes from the need for advanced electronics, new semiconductor packaging tech, and precise soldering.

What are the key challenges in implementing vacuum eutectic reflow ovens?

Big challenges include high start-up costs, complex operation, and the need for special training. Also, there’s the issue of energy use and environmental effects from soldering.

Which countries are leading in vacuum eutectic reflow oven technology?

The US, China, and Japan lead in this tech. They drive innovation with strong semiconductor sectors, R&D, and advanced manufacturing.

What types of vacuum eutectic reflow ovens exist?

There are convection, vapor phase, and infrared ovens. Recent tech has improved heating, temperature control, and vacuum systems in these ovens.

What are the primary applications of vacuum eutectic reflow ovens?

These ovens are key in SMT assembly, advanced packaging, semiconductor making, and new fields like MEMS and 3D packaging.

How are geopolitical factors affecting the vacuum eutectic reflow oven market?

Trade policies, tariffs, and tensions between big markets like the USA and China are big issues. They affect production, distribution, and where electronics are made.

What emerging technologies might impact vacuum eutectic reflow ovens?

Future tech could include laser-assisted systems, AI control, advanced additive manufacturing, and new packaging for quantum computing.

How is Industry 4.0 influencing vacuum eutectic reflow oven design?

Industry 4.0 is making ovens smarter with advanced sensors, real-time monitoring, predictive maintenance, and data use. This improves how ovens are designed and run.